Novel high-performance TPU composite material and preparation method thereof

A technology of composite materials and pellets, applied in textiles and papermaking, fiber treatment, physical treatment, etc., can solve the problems of not being widely used, insufficient mechanical strength, poor air permeability, etc., to increase physical and mechanical properties and aesthetics, improve Degree of diversification, effect of increasing tensile strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

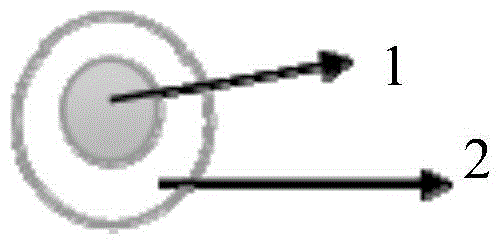

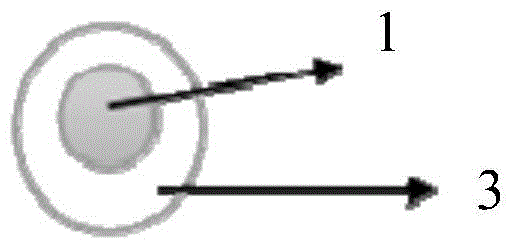

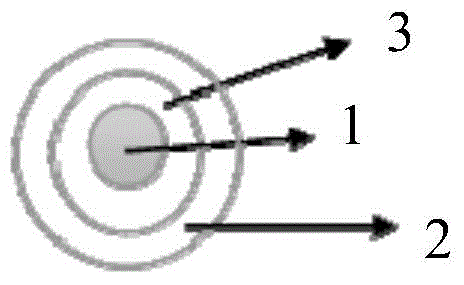

Image

Examples

Embodiment 1

[0050] Carry out the preparation of TPU composite material according to the following steps:

[0051] (1) Proportioning of raw materials by weight: 63 parts of TPU film; 20 parts of silk thread, 17 parts of auxiliary agent, wherein the auxiliary agent is 10 parts of compatibilizer maleic anhydride-styrene copolymer (SMA), antioxidant Cyanox1790 , 5 parts, 2 parts of lubricant polysiloxane;

[0052] (2) Carry out pretreatment to silk thread, comprise adopting water curtain jetting and low-oxygen plasma treatment; Wherein, described water curtain jetting is to adopt the tiny water flow that produces 0.11mm from the porous jetting plate of 100 holes / m to form water curtain Shocks the wire and produces a 1.8×10 8 The pressure of Pa reaches the speed of 410m / s; The described hypoxic plasma treatment conditions are: time 15min, pressure 60Pa, power 80W;

[0053] (3) Put the TPU film material into the hopper, after sealing the hopper, dry and dehumidify for 2 hours at 80°C, start t...

Embodiment 2

[0056] Carry out the preparation of TPU composite material according to the following steps:

[0057] (1) Proportioning of raw materials by weight: 68 parts of TPU hot melt adhesive; 17 parts of cotton thread, 15 parts of auxiliary agent, wherein the auxiliary agent is 8 parts of compatibilizer maleic anhydride-styrene copolymer (SMA), antioxidant Agent Cyanox1790, 4 parts, the lubricant is 3 parts of polysiloxane and pentaerythritol stearate with a weight ratio of 1:1;

[0058] (2) Cotton thread is pretreated, including adopting water curtain jetting and hypoxic plasma treatment; Wherein, described water curtain jetting is to adopt the tiny water flow that produces 0.12mm from the porous jetting plate of 110 holes / m to form water curtain Shocks the cotton thread and produces a 2.0×10 8 The pressure of Pa reaches the speed of 420m / s; the described low-oxygen plasma treatment conditions are: time 18min, pressure 70Pa, power 90W;

[0059] (3) Put the TPU melt material into the...

Embodiment 3

[0062] Carry out the preparation of TPU composite material according to the following steps:

[0063] (1) Proportion of raw materials by weight: 30 parts of TPU film, 40 parts of TPU melt glue; 10 parts of silk thread, 8 parts of cotton thread, 12 parts of auxiliary agent, wherein the auxiliary agent is a compatibilizer maleic anhydride-styrene copolymer (SMA) 8 parts, antioxidant Irganox1076, 3 parts, lubricant polysiloxane 1 part.

[0064] (2) Pretreatment of silk thread and cotton thread, including water curtain jetting and low-oxygen plasma treatment; wherein, the water curtain jetting is formed by using a 0.15mm fine water flow from a porous jetting plate of 120 holes / m The water curtain impacts the silk thread and cotton thread, and produces 2.2×10 8 The pressure of Pa reaches the speed of 450m / s; the described hypoxic plasma treatment conditions are: time 25min, pressure 100Pa, power 100W;

[0065] (3) Add TPU film and hot melt adhesive material into the hopper, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com