Torsional high-accuracy micro-thrust measuring system

A measurement system and high-precision technology are applied to the high-precision micro-thrust measurement system for the experimental research of micro-thrusters for aerospace devices. It can solve the problems such as difficulty in accurate measurement of thrust of micro-thrusters, influence on measurement accuracy, and influence on accuracy, and achieve good application prospects, high precision, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

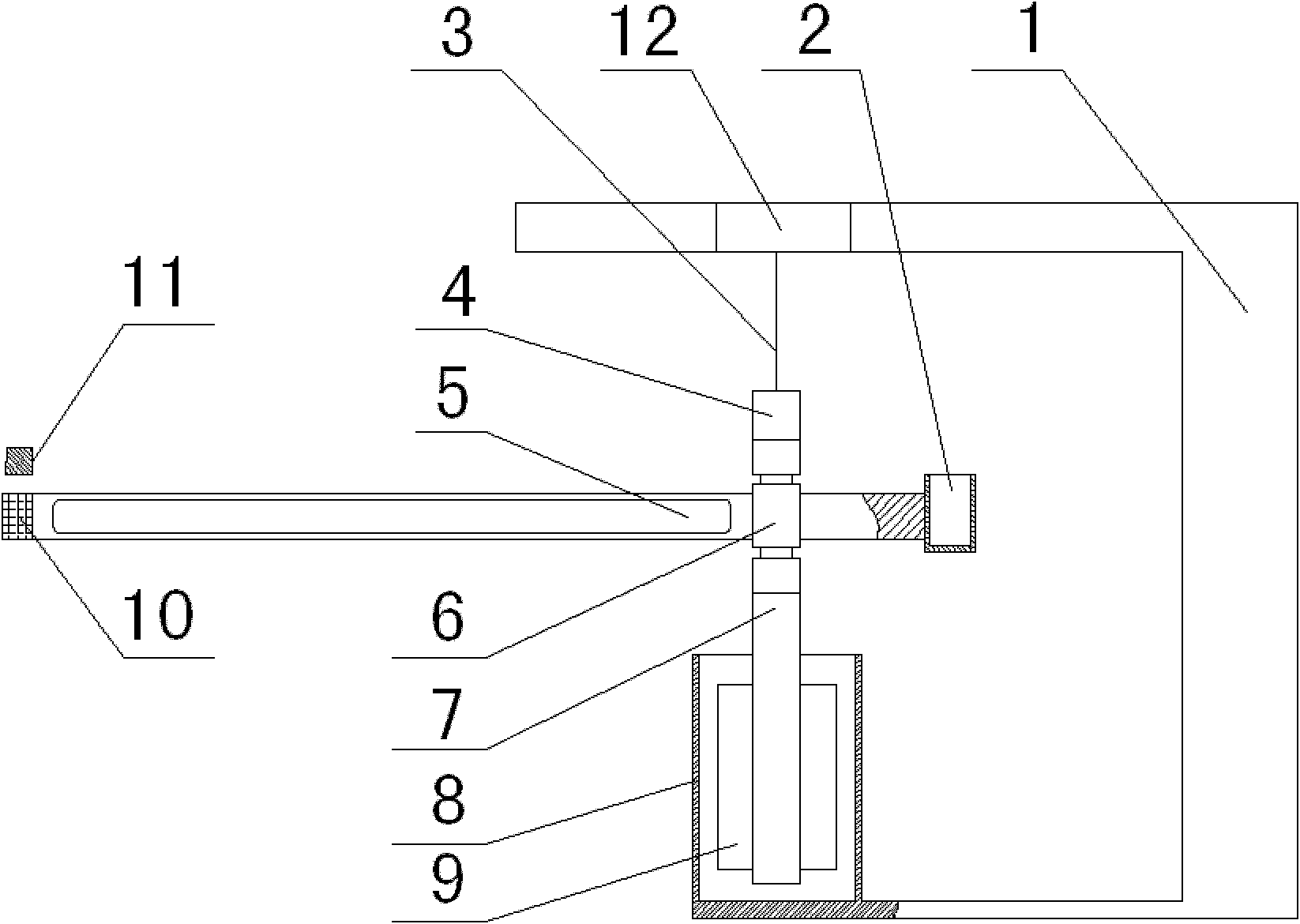

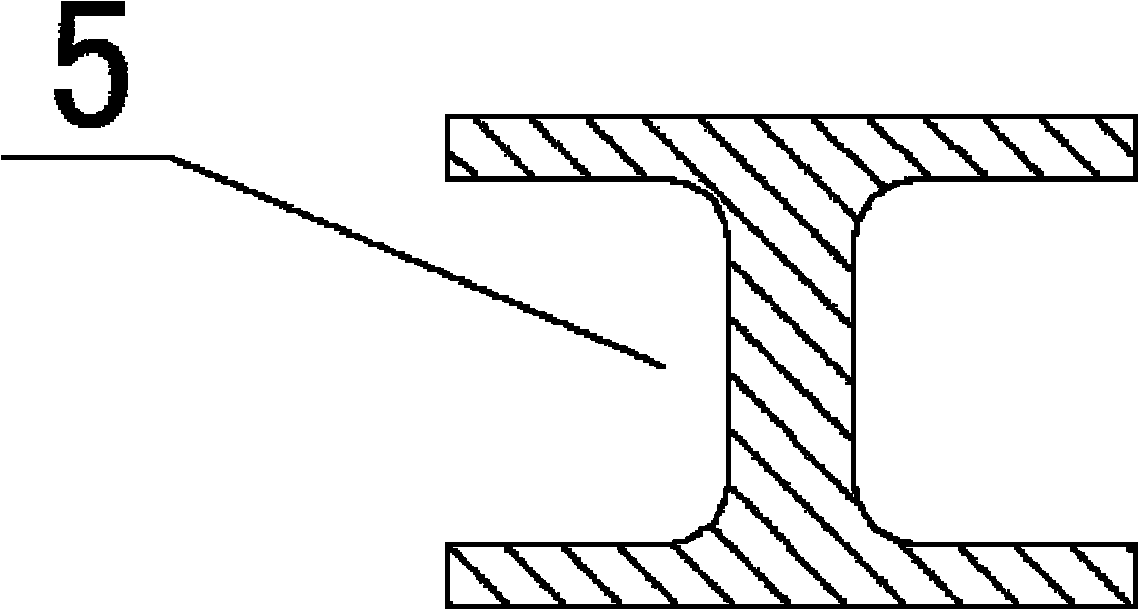

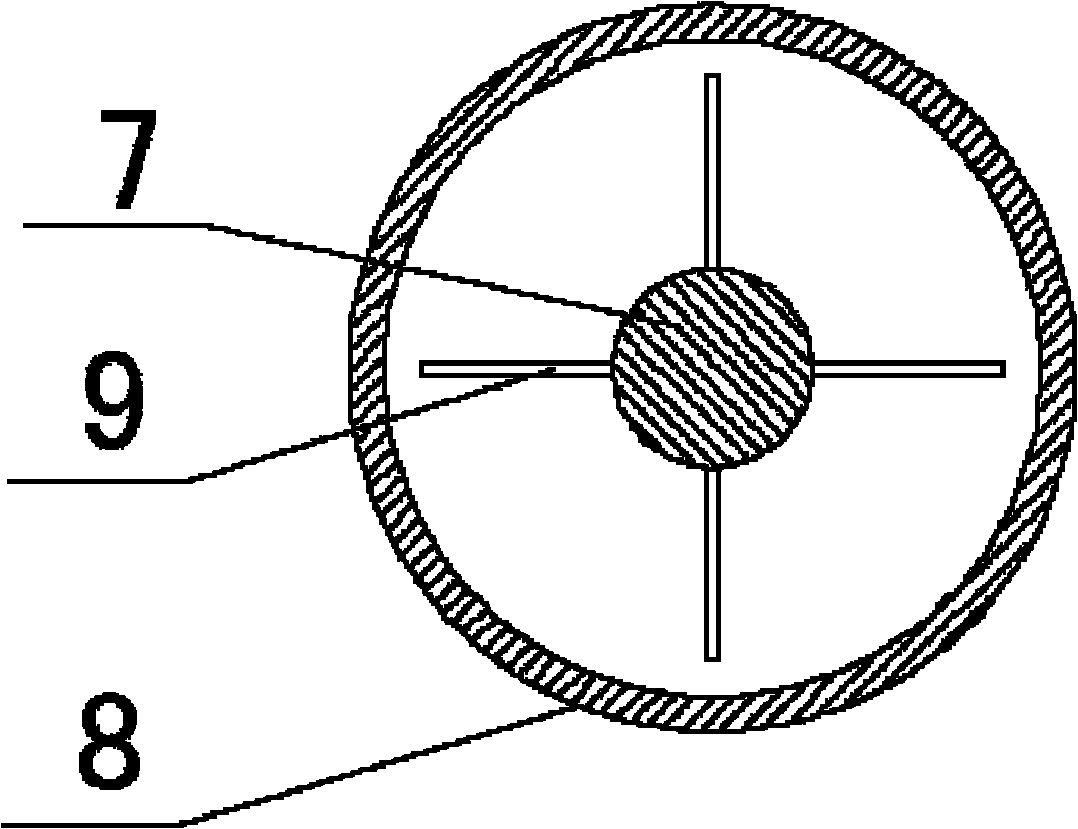

[0022] see figure 1 As shown, the torsion-type high-precision micro-thrust measurement system of the present invention mainly includes: a support frame 1, a connecting line 3, a thrust lever 5, a flexible hinge 6, a rigid shaft 7, a fin structure 9 and a linear displacement sensor 11. The crossbar of the support frame 1 is provided with a position regulator 12, the bottom end of the rigid shaft 7 is connected with a paraffin curing cup 8, and the fin structure 9 is arranged in the paraffin curing cup 8, and is symmetrical with the rigid shaft 7 as the central axis. Located on the lower part of the rigid shaft 7, a micro propeller 10 is provided on the long arm end of the thrust lever 5, and a linear displacement sensor 11 matched with the micro propeller 10, and a counterweight cup 2 is provided on the short arm end of the thrust lever 5; The thrust lever 5 is connected with the top end of the rigid shaft 7 to maintain a horizontal state through a flexible hinge 6 and installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com