Ladder winding method for transformer type sensor coil

A sensor coil and transformer-type technology is applied in the field of stepped winding of transformer-type sensor coils, which can solve the problems of increasing difficulty in sensor development and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

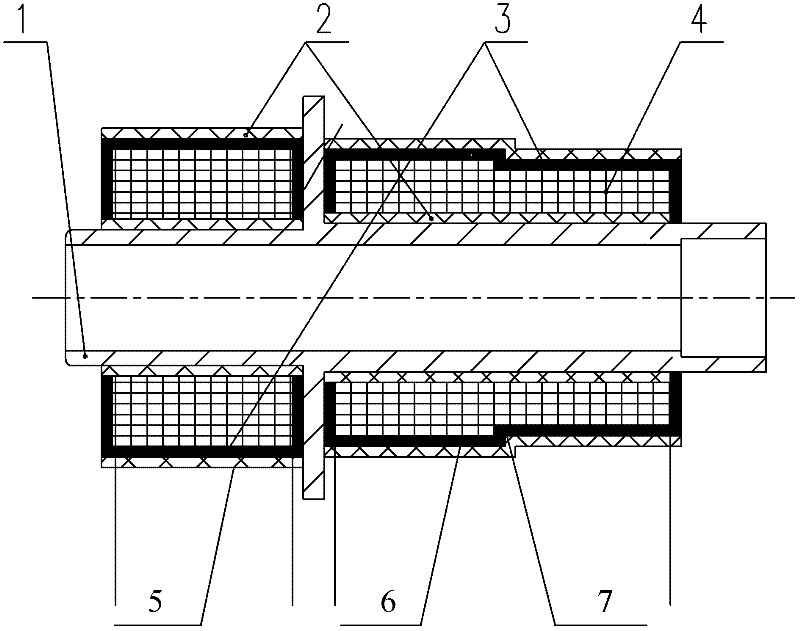

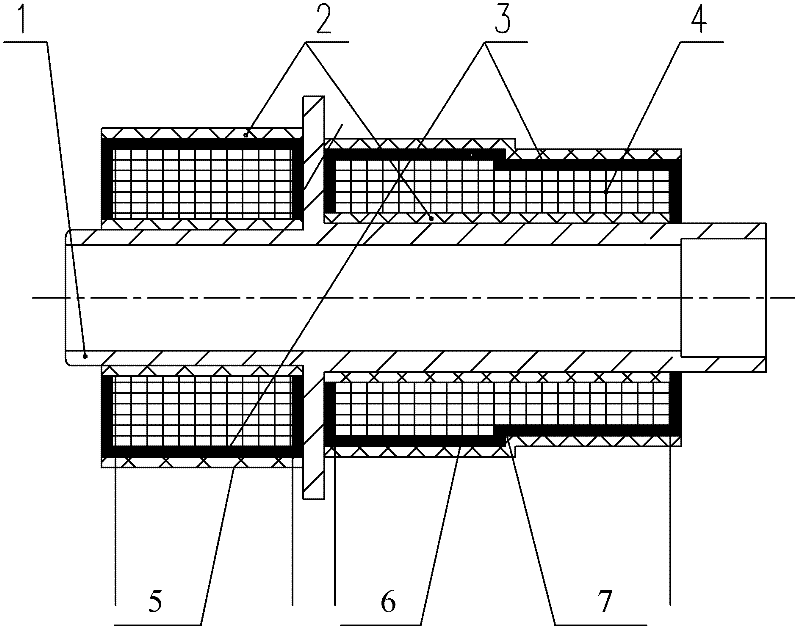

[0016] Attached below figure 1 An embodiment of the present invention is described.

[0017] The step winding method of transformer type sensor coil includes the following steps:

[0018] 1) Wrap the alkali-free glass fiber cloth 2 impregnated with insulating varnish on the outer surface of the winding area of the skeleton 1, and the outer surface of the winding area of the skeleton 1 is wrapped with two layers of alkali-free glass fiber cloth 2 to improve the insulation performance of the skeleton 1 .

[0019] 2) Put the wrapped skeleton 1 into a drying box, heat it up to 200°C, keep it warm for 2 hours, and take it out;

[0020] 3) Wind the enameled round copper wire 4 in the winding area of the skeleton 1 after drying. For each layer, apply a layer of insulating varnish on the enameled round copper wire 4 until the specified number of layers are wound in parallel. The primary coil 5 and the secondary coil 6 are wound;

[0021] 4) The enameled round copper wire 4 is wound in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com