Movable operation platform for installing hydraulic cylinder of ladle slide gate

A technology of operation platform and movable platform, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., and can solve problems such as economic waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

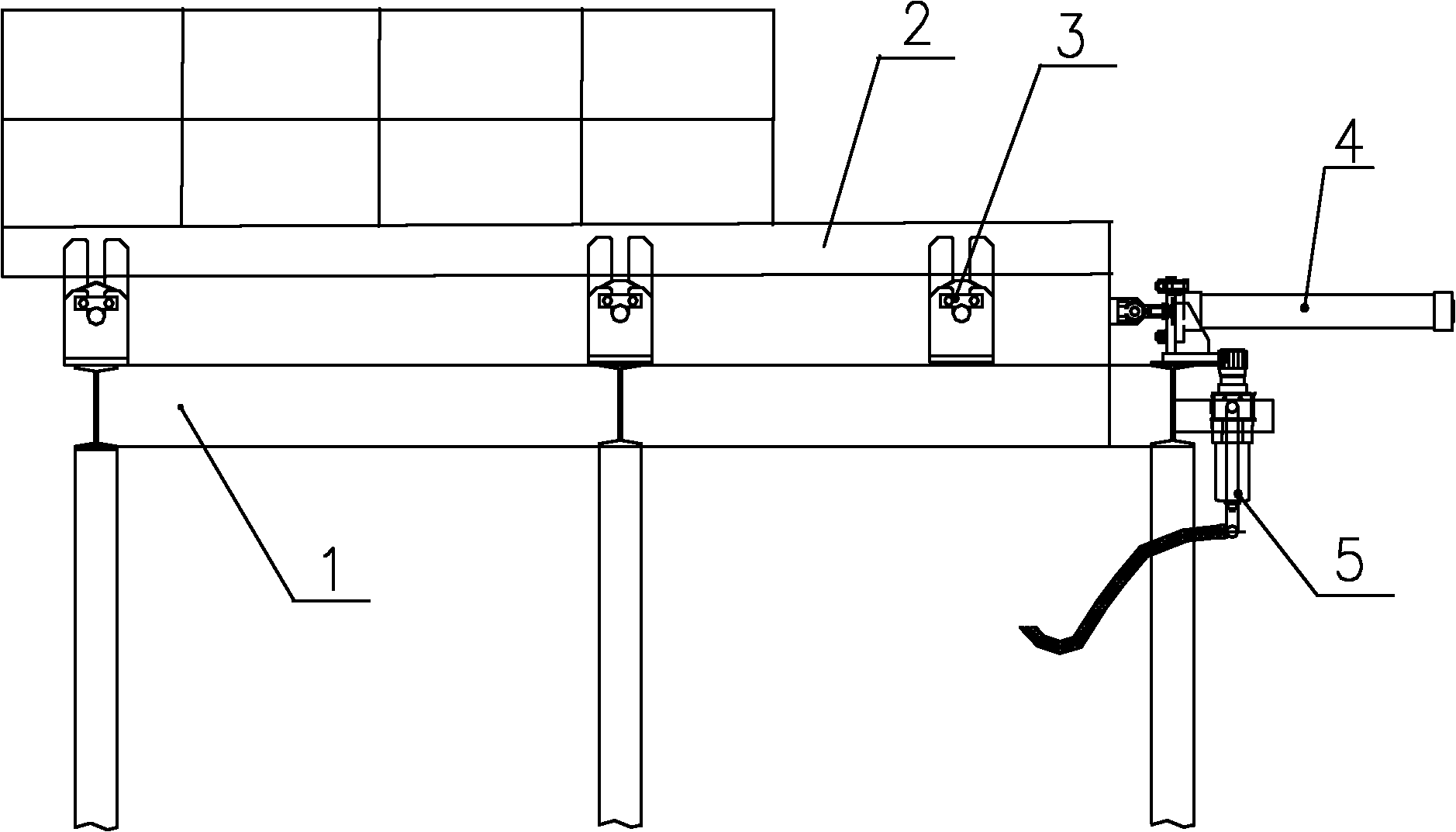

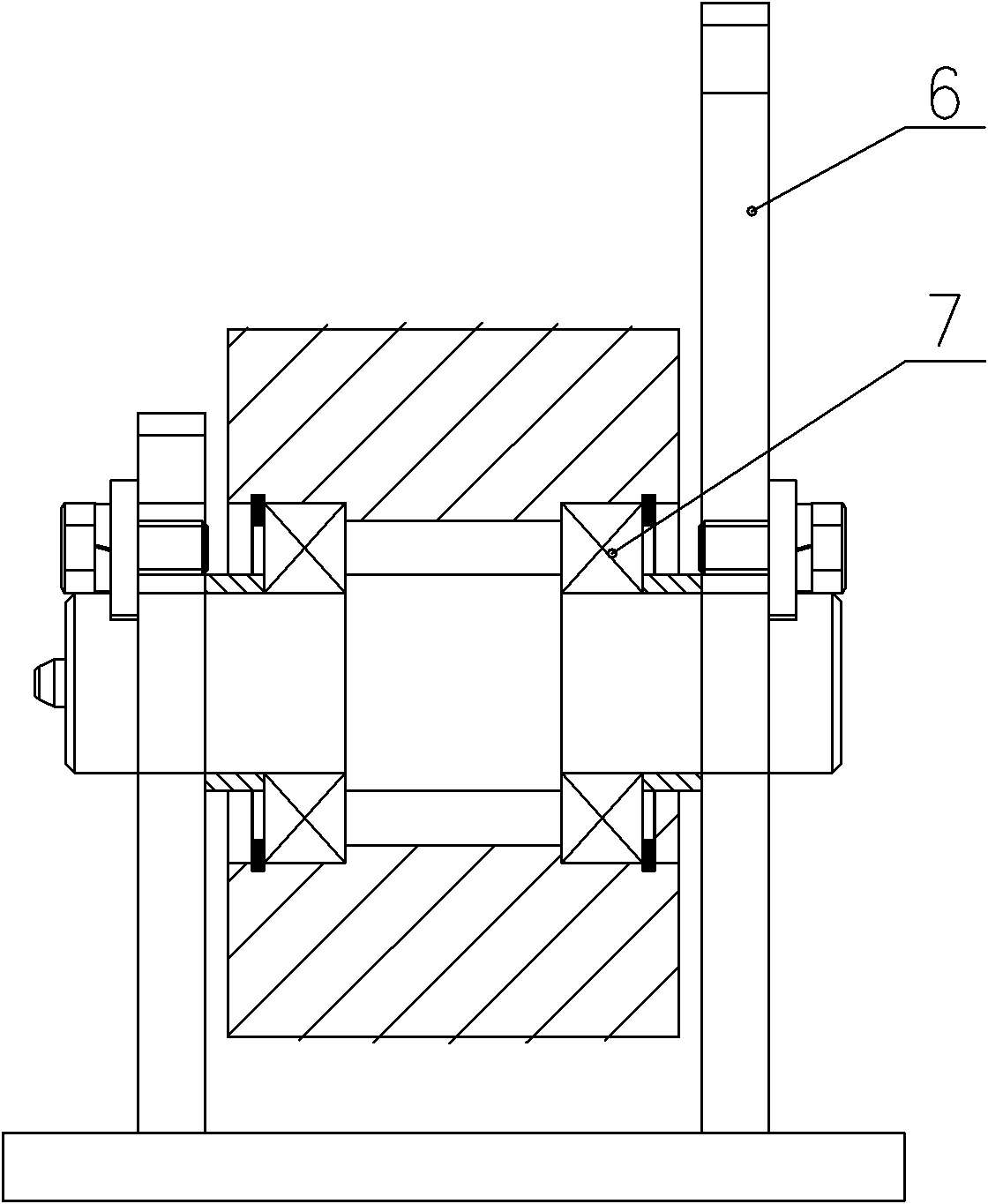

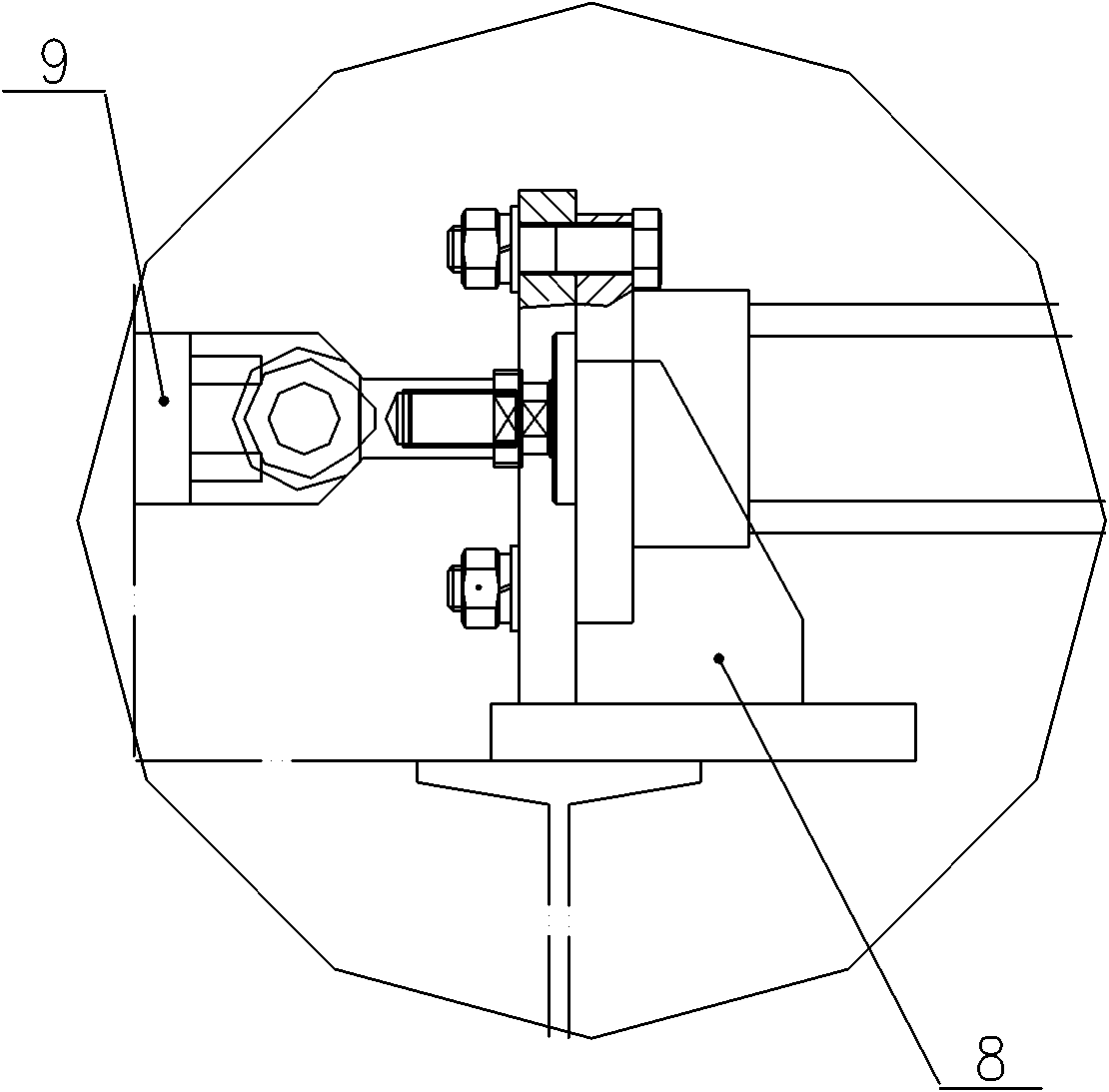

[0020] The movable operating platform provided by the present invention for installing the ladle sliding nozzle hydraulic cylinder is a scalable movable operating platform, and its structure is as follows: figure 1 Shown: including fixed platform 1, movable platform 2, roller 3 and pneumatic system and other parts. Wherein: the bottom of movable platform 2 is provided with roller 3 and positioning hook, and this movable platform is supported on the fixed platform 1 by roller 3 activities, and movable platform 2 is hooked on the fixed platform 1 by positioning hook when advancing to the end point on fixed platform 1. Bottom, to prevent movable platform 2 from tipping over. The forward and backward movement of the movable platform 2 is driven by a pneumatic system.

[0021] The fixed platform 1 is used for the support of the movable platform 2 . The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com