Vibration-damping and locking integrating device of chassis suspension fork of vehicle

A chassis and suspension technology, applied in suspension, elastic suspension, vehicle parts, etc., can solve the problems of complex structure, large chassis space, failure of mechanical locking device, etc., to achieve high action sensitivity, simple working process, occupancy small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

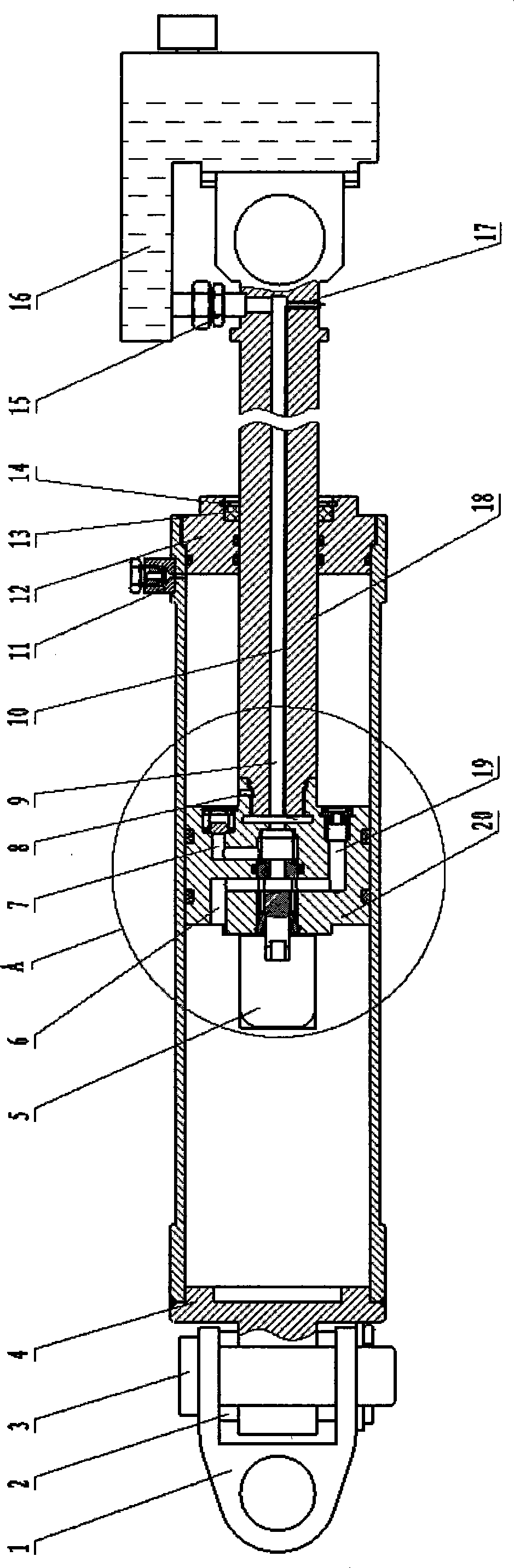

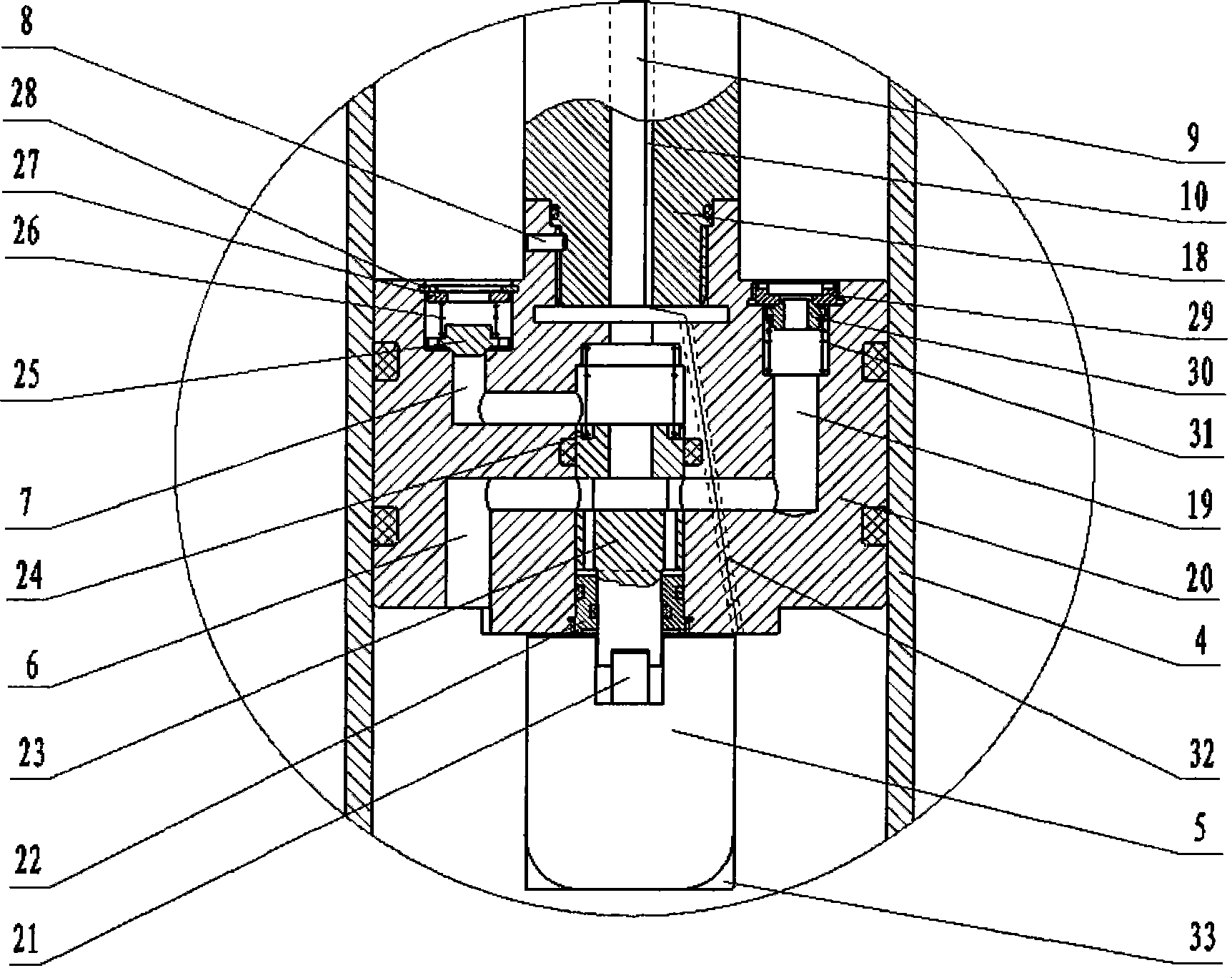

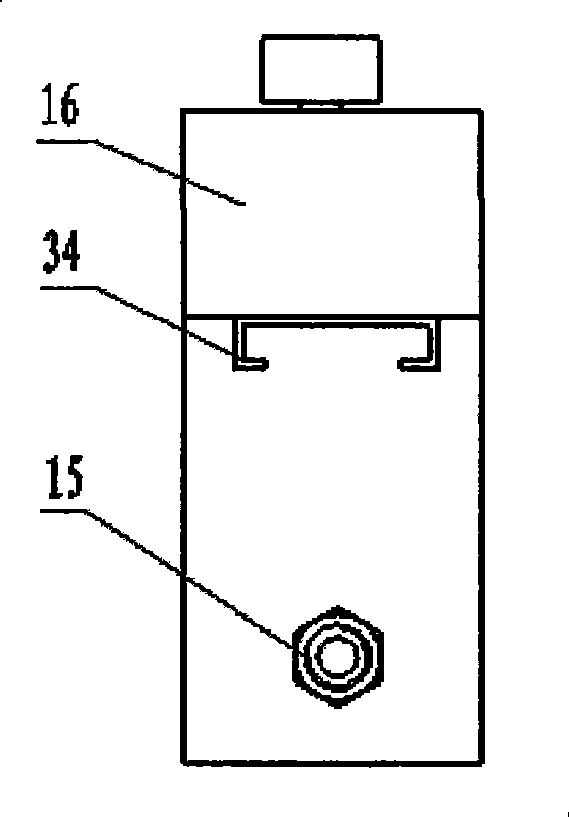

[0025] Such as Figure 1-3 Shown: an integrated vehicle chassis suspension vibration damping and locking device, mainly including a piston rod 18, a cylinder 4, a piston 20, a lock valve 23, a DC electromagnet 5, an oil storage tank 16, and the like. The end cover at the lower end of the cylinder 4 is fixedly connected with an adapter 1 with lifting lugs through the bushing 2 and the pin shaft 3, and the lifting lugs are fixed on the axle through the pin shafts and pins. The piston 20 of the piston rod 18, the piston 18 divides the inner cavity of the cylinder barrel 4 into two upper and lower cavities that are not communicated with each other. The top of the cylinder barrel 4 is equipped with a guide seat 12, the guide seat 12 is tightly connected with the cylinder barrel 4 through threads, and a sealing ring is respectively arranged between the guide seat 12 and the cylinder barrel 4, the guide seat 12 and the piston rod 18, for Prevent oil leakage during work. A dust-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com