A binding method for heat treatment of square workpieces

A technology for workpieces and squares, which is applied in the field of bundling for heat treatment of square workpieces, can solve the problems of unresolved workpiece placement and removal convenience, and achieve the effect of improving processing quality and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

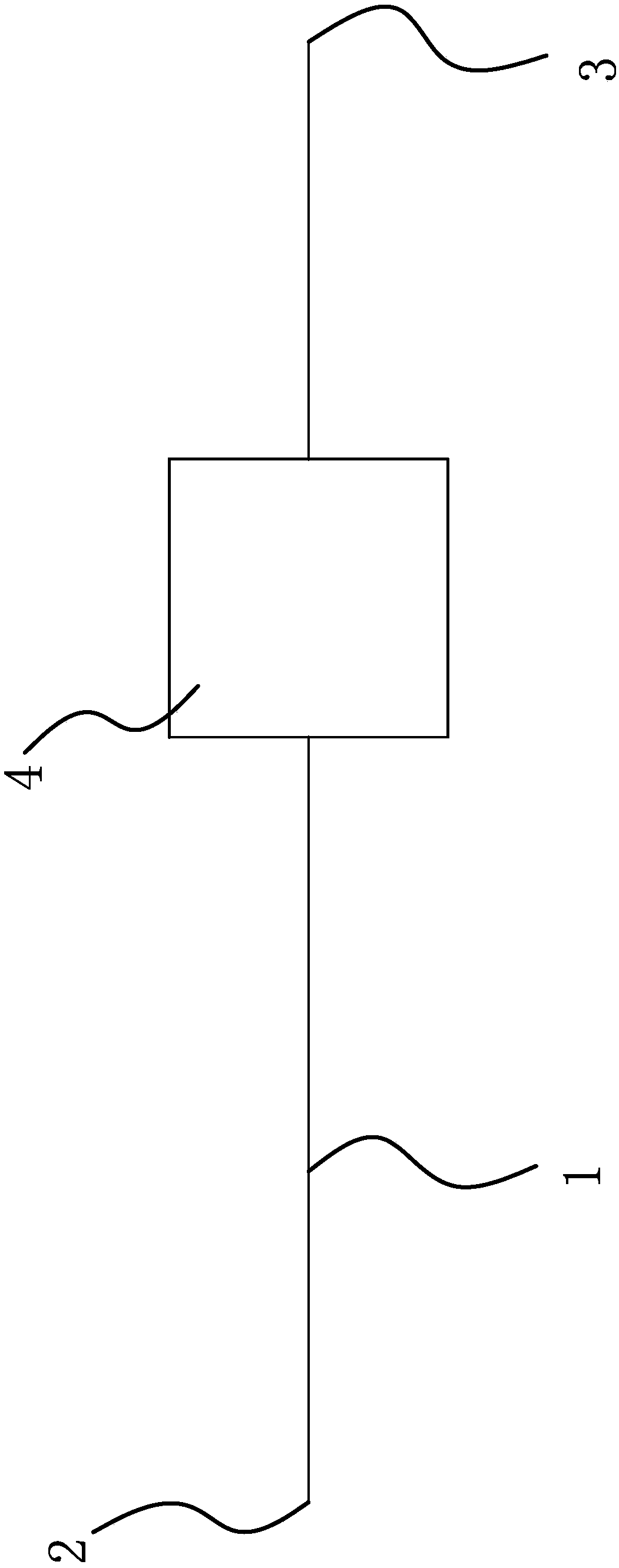

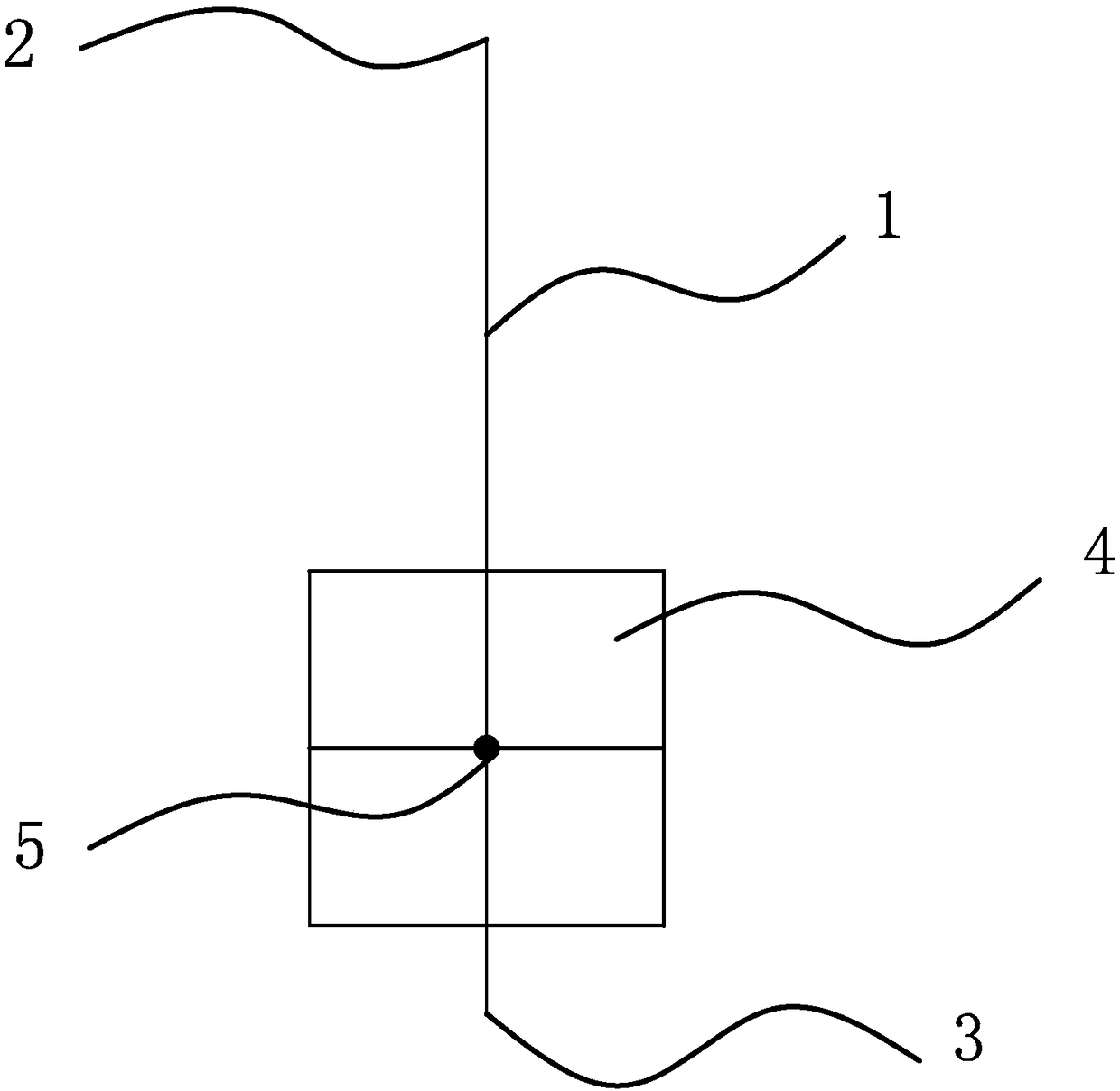

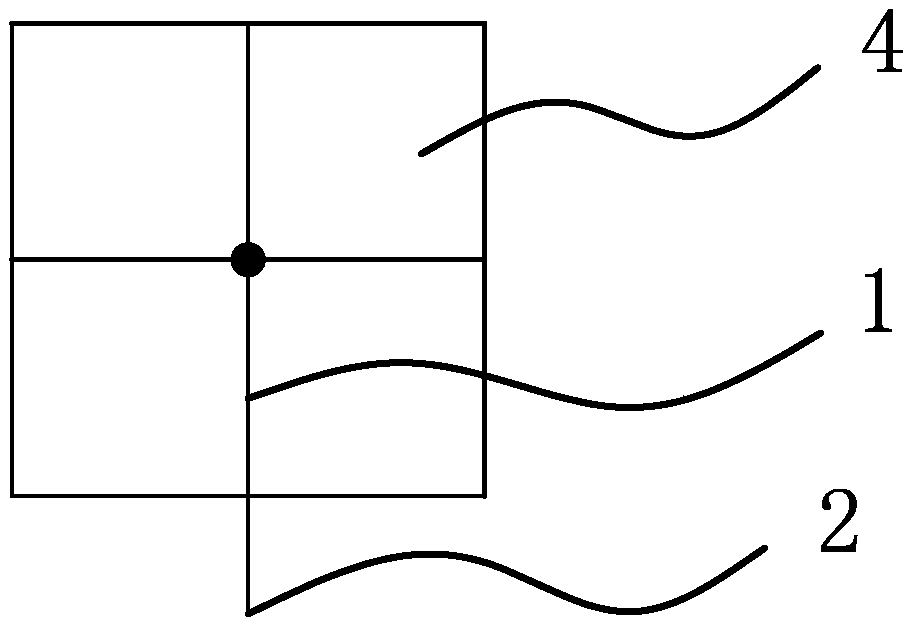

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] Assuming that the side length of the square workpiece 4 is a and the thickness is b, it also utilizes a binding device, the binding device includes a platform 9, the center of the platform 9 is provided with a platen 10 for placing the square workpiece 4, and the two sides of the platen 10 Side activity is provided with the clamping plate 11 that is used for fixing the square workpiece 4 on the platen 10 . Specifically, the splint 11 is fixed on the platform 9 through the air cylinder 12 . The upper surface of the platen 10 is provided with a groove 13 for the iron wire 1 to pass through, the groove 13 runs through the left side and the right side of the platen 10 , and the left side of the platen 10 is also provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com