Bundling method for brick blank mixed material heat value measurement

A technology of mixing materials and wrapping method, which is applied in the direction of thermal development of materials and preparation of test samples, etc. It can solve the problems of inability to preheat the brick adobe mixture, large calorific value error, and inability to guide the normal production of brick and tile enterprises. Operation and method are simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

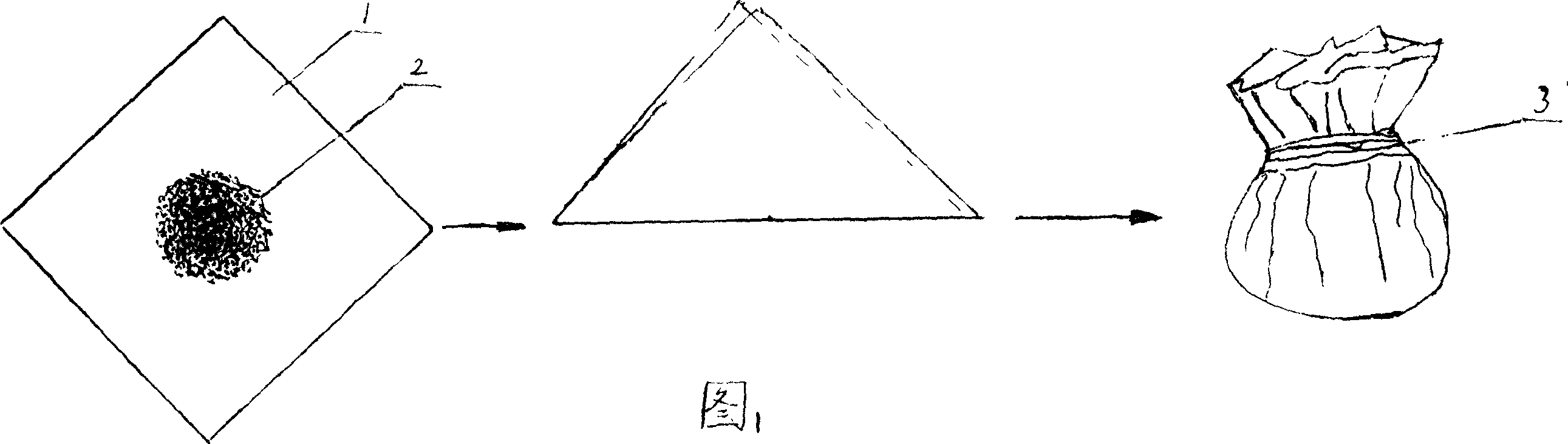

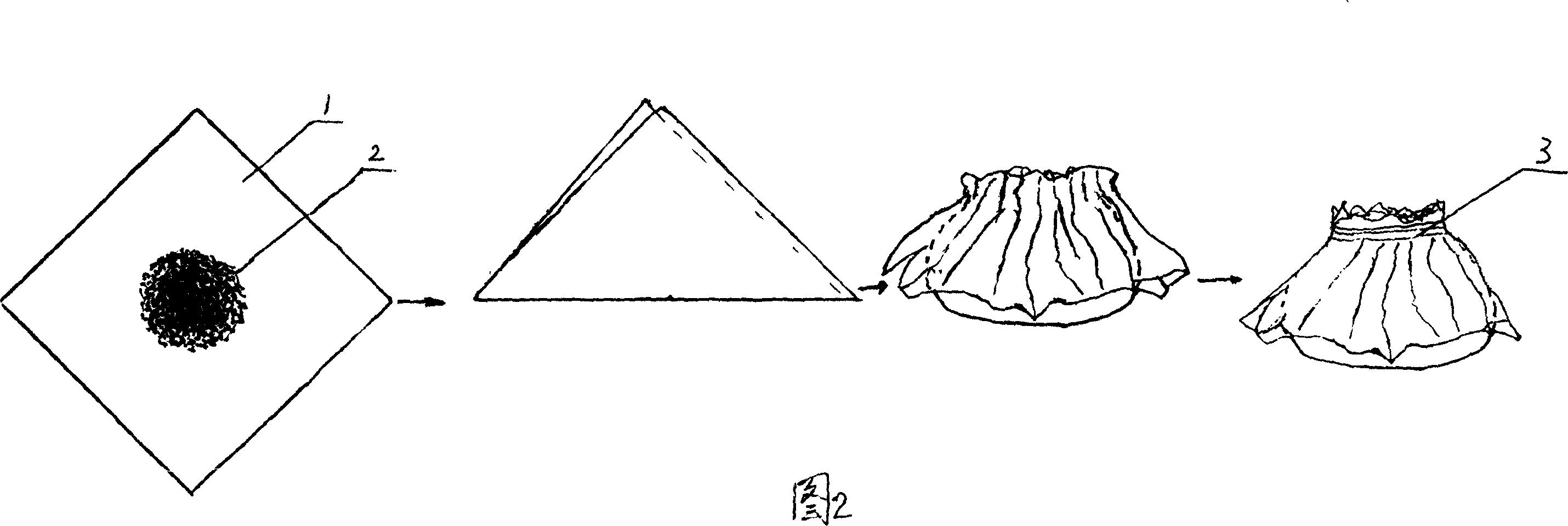

[0013] As shown in Figure 2, the spherical wrapping method for measuring the calorific value of the brick adobe mixture is: first spread out the wrapping paper 1, and what wrapping paper is used in this embodiment is square paper, and circular paper can also be used; Place the brick adobe mixture 2 at the center of the wrapping paper 1, fold the wrapping paper in half diagonally, then tighten the upper part of the wrapping paper wrapped with the brick adobe mixture after folding in half, and finally tighten the wrapping paper after the upper part is tightened Tie up the top with cotton thread 3 and get final product after being folded down.

[0014] Put the bundled adobe mixture into the oxygen bomb according to the conventional heat value measurement method, and fill it with oxygen to burn. After testing, the error is ±8 kcal, and the error is within the range of ±20 kcal stipulated by the state.

Embodiment 2

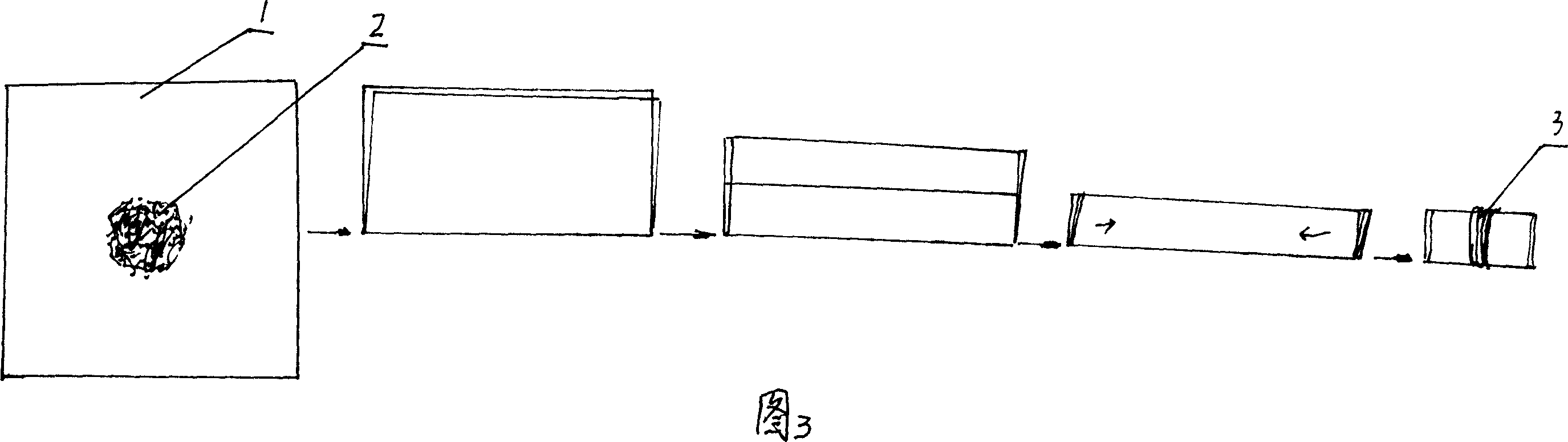

[0016] As shown in Figure 3, the roll-up wrapping method is to fold the wrapping paper 1 with the brick adobe mixture 2 horizontally in half and fold it into a roll, then fold it from both ends to the middle, and then tie it tightly with cotton thread 3 in the middle. .

[0017] Put the bundled adobe mixture into the oxygen bomb according to the conventional heat value measurement method, and fill it with oxygen to burn. After testing, the error is ±11 kcal, which is within the range of ±20 kcal stipulated by the state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com