Bundling method and auxiliary bundling device for disc-shaped workpiece heat treatment

A technology for bundling device and workpiece, applied in the field of machinery, can solve problems such as not being very good, and achieve the effects of improving processing quality, improving bundling efficiency, and being convenient and quick to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0037] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the binding method of the disc-shaped workpiece comprises the following steps:

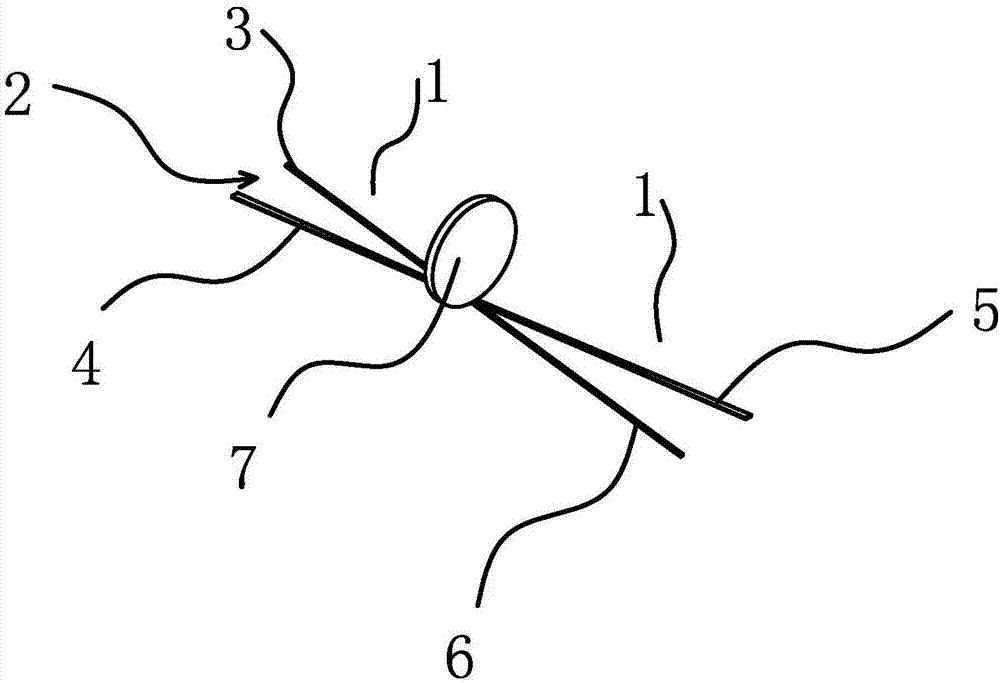

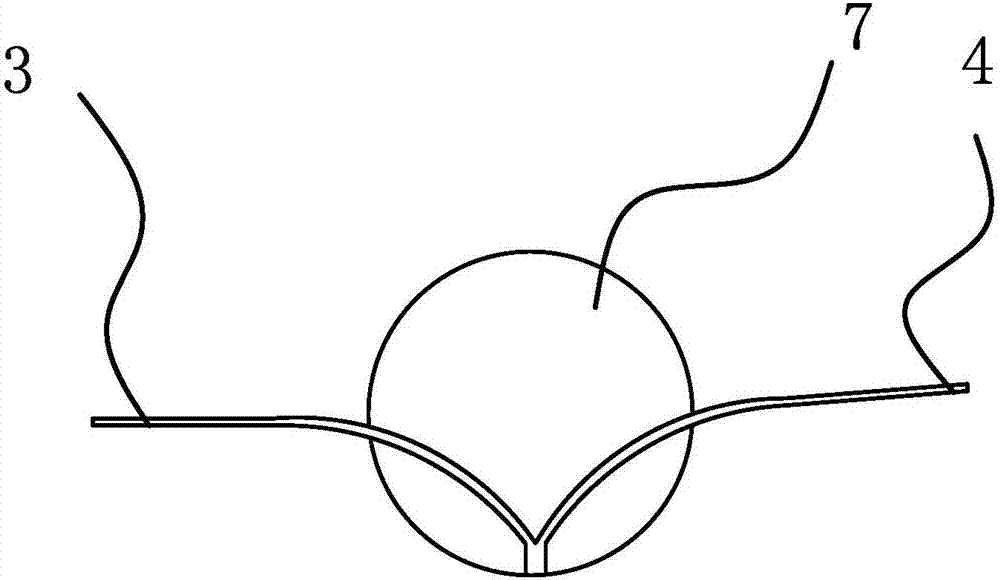

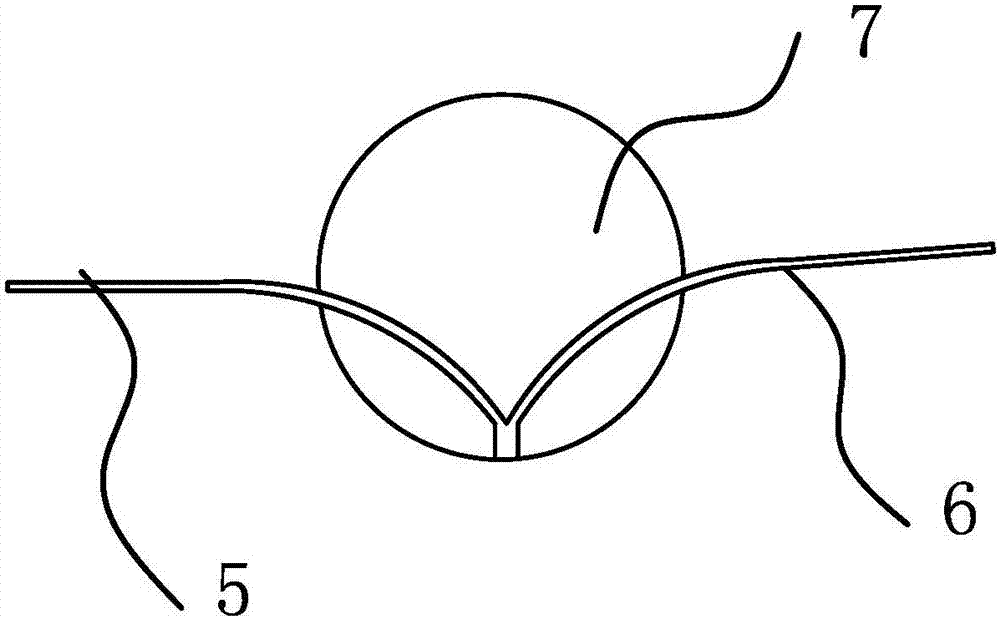

[0038] 1), take two iron wires 1 with the same length, cross the middle parts of the two iron wires 1 and twist them into a twisted shape, the length of the twisted part of the iron wires 1 is greater than the thickness of the disc-shaped workpiece 7;

[0039] Define the twisted X-shaped two iron wires 1 as iron wire group 2, define the two branches at the left end of X-shaped iron wire group 2 as A section 3 and B section 4, and define the X-shaped iron wire group at the right end. The two branches are defined as section C 5 and section D 6, and the middle part of wire grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com