Single-chip microcomputer base with damping function

A technology of single-chip microcomputer and machine base, which is applied in manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of skewed pins, affecting the quality of single-chip microcomputers, and collision between pins and mounting holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

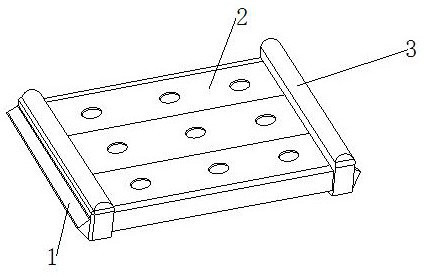

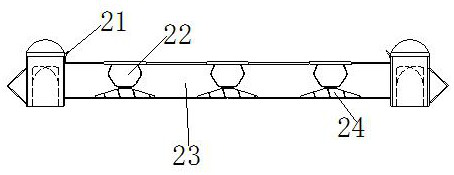

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The invention provides a single-chip microcomputer base with a shock-absorbing function, and its structure includes an extension board 1, an insertion board 2, and a clamping board 3. The extension board 1 is welded and connected to the outside of the clamping board 3, and the insertion board 2 is embedded and connected. Between the clamping plates 3; the inserting plate 2 is composed of a clip 21, a mounting hole 22, a horizontal plate 23, and a top block 24. The clip 21 is movably engaged on the left and right sides of the upper end of the horizontal plate 23, and the installation The hole 22 is connected by riveting to the upper end of the top block 24 , and the top block 24 is welded to the inner lower end of the horizontal plate 23 .

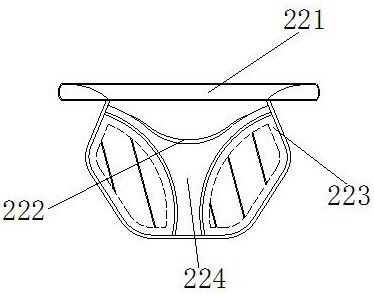

[0031] Wherein, the installation hole 22 is composed of a fitting device 221, an insertion ring 222, a curved plate 223, and an extruding device 224. The laminating device 22...

Embodiment 2

[0038] As attached 7 to attached Figure 9 Shown:

[0039]Wherein, the laminating device 221 is composed of an inner layer 211, a hollow groove 212, a pressing plate 213, and a fixing plate 214. The hollow groove 212 is located between the pressing plates 213, and the pressing plate 213 is embedded and connected to the fixing plate 214. On the inner side, the fixing plate 214 is fixedly installed on the inner side of the inner layer 211, and the pressing plate 213 is symmetrically installed on the left and right sides of the hollow groove 212, and is made of elastic material. Fixed to avoid offset during processing.

[0040] Wherein, the pressing plate 213 is composed of a contact plate 131, a telescopic part 132, and a connecting plate 133. The telescoping part 132 and the connecting plate 133 are an integrated structure, and the connecting plate 133 is embedded and connected to the right side of the contact plate 131. The telescopic parts 132 are installed in a triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com