Glue Thawing Stand

A glue and glue bottle technology, applied in the field of thawing brackets, can solve the problems of wasting glue, corroding the workbench and contact personnel, wasting glue and components, etc., and achieve the effect of improving work efficiency and enlarging the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

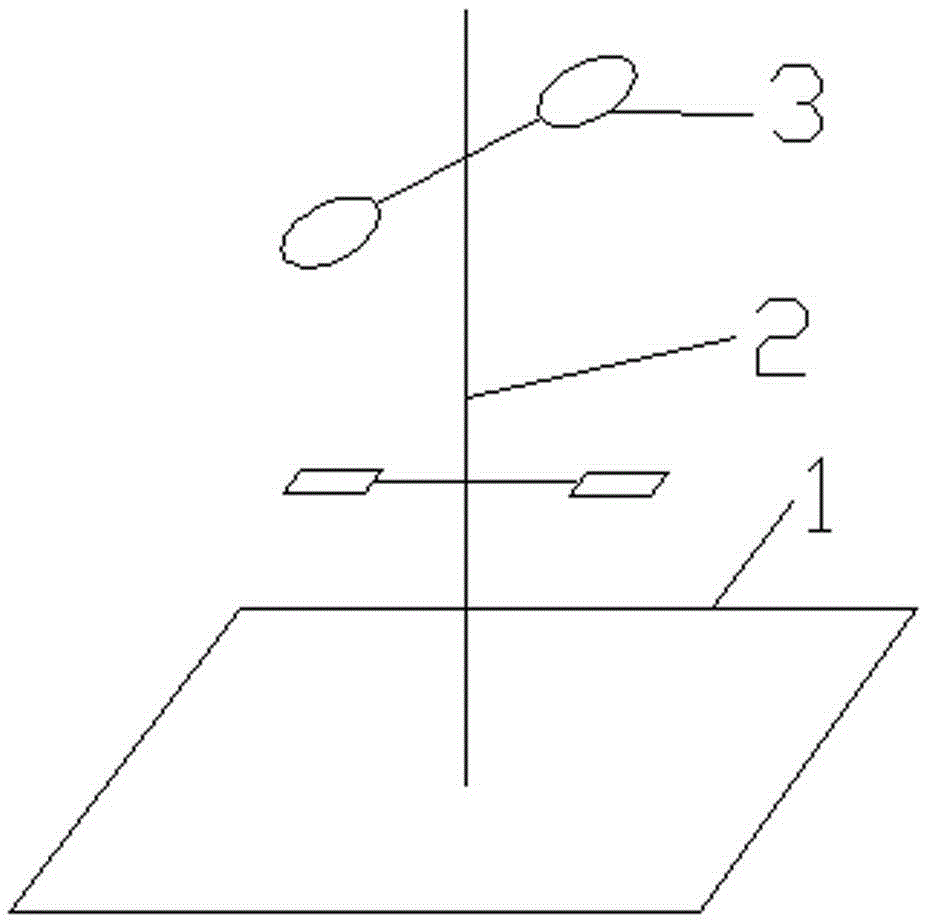

[0013] As shown in the accompanying drawings, the glue thawing support includes a base plate 1 and a support 2 vertically arranged on the base plate. The support 2 is horizontally provided with a hollow suspension frame 3 carrying a glue bottle to be thawed. The suspension frames 3 on the horizontal plane are arranged alternately; the suspension frames set on different heights of the supports have different shapes and are used to carry different types of glue bottles to be thawed, while the suspension frames set at the same height of the supports have the same shape and are used to carry the same type of unfreezing glue bottles. Thaw glue bottle; Suspension frame 3 is preferably the stainless steel frame of corrosion resistance of glue, and base plate 1 is preferably the stainless steel plate of resistance to glue corrosion, and the surface of base plate 1 can also bond the test paper inspection layer, so that when glue leakage occurs, the glue falls on the base plate, The glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com