Mixed construction waste sorting comprehensive treatment system and method

A comprehensive treatment and garbage technology, applied in the field of construction mixed waste sorting and comprehensive treatment system, can solve the problems that it is difficult to prepare and meet various national standards, and cannot realize high value-added utilization of construction mixed waste, so as to facilitate recycling And produce renewable energy, shorten comprehensive processing time, mature and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

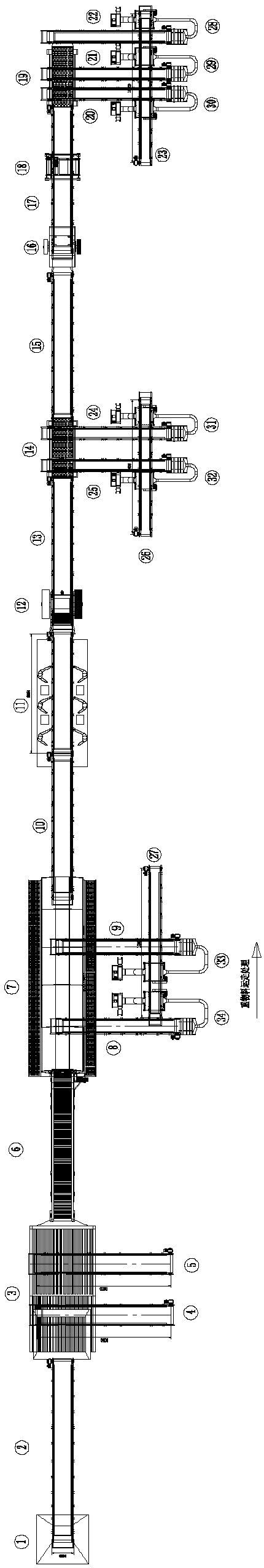

[0050] Such as figure 1 As shown in FIG. 1 , it shows a schematic structural view of the construction mixed waste sorting comprehensive treatment system of the present invention. The system includes an upper bin 1 for construction mixed waste, and the upper bin 1 is connected to a feeding screening machine 3 through an upper belt conveyor 2 . In this embodiment, the feeding screening machine 3 is connected with a belt conveyor 4 for materials below 5mm and a belt conveyor 5 for materials with a thickness of 5-10mm. The main body of the feeding screening machine 3 is connected to the drum screening machine 7 through the chain conveyor 6, and the middle part of the chain conveyor 6 is also connected with a first iron remover (not shown), the first iron remover is a straddle-type magnetic separator and a permanent The magnetic drum magnetic separator cooperates with the composite device for magnetic separation. In this embodiment, the drum screening machine 7 is connected with ...

Embodiment 2

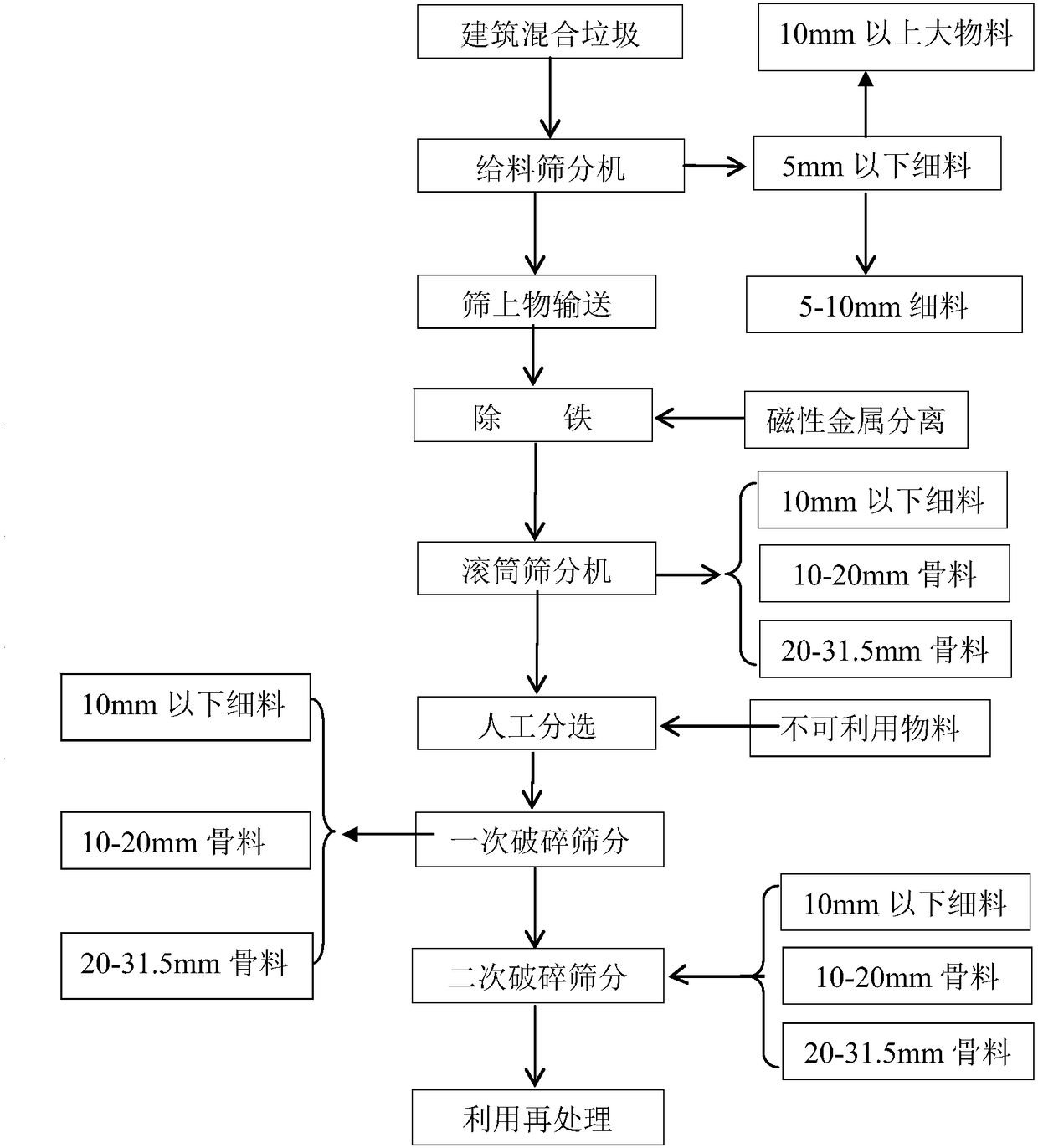

[0052] see figure 2 , shows a schematic diagram of the construction mixed waste sorting comprehensive treatment method and process flow of the present invention. In this embodiment, the process flow includes the following:

[0053] 1) Sieve the mixed construction waste through a feeding screening machine, and screen out fine materials with a particle size below 5mm and a size of 5-10mm, as well as large mixed materials with a particle size above 10mm;

[0054] 2) Convey the sieve and remove the magnetic metal components through the iron remover;

[0055] 3) Dispersing and separating the materials from which magnetic metal components have been removed by a drum screening machine to obtain aggregates with sizes below 10mm, 10-20mm and 20-31.5mm;

[0056] 4) manually sorting the remaining materials in step 3) to remove unavailable materials;

[0057] 5) Then through one-time crushing and screening, aggregates of different specifications below 10mm, 10-20mm and 20-31.5mm are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com