Automatic remnants removing device of engine cylinder body

An engine block and automatic technology, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. It can improve the production efficiency, reduce the manual work, and remove the debris cleanly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

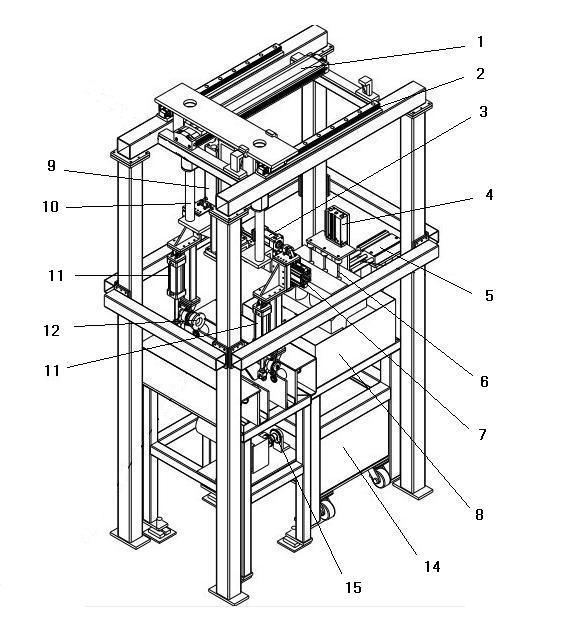

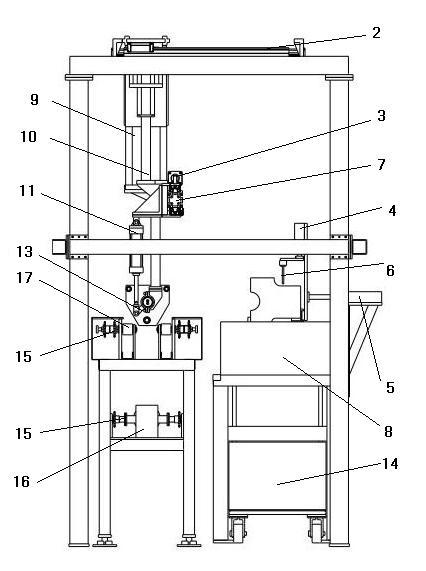

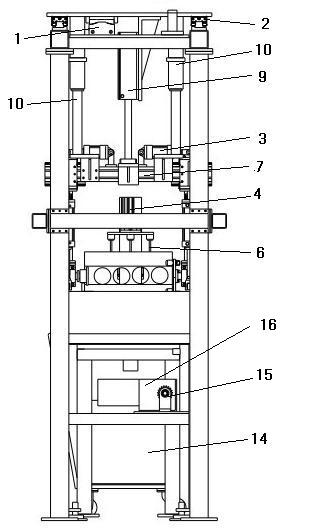

[0014] Example: see figure 1 , figure 2 , image 3 .

[0015] An automatic chip removal device for an engine cylinder, comprising a turning and moving positioning mechanism, a vibration mechanism 8, a high-pressure air blowing mechanism, a product delivery mechanism, an automatic control system, and a debris collection vehicle 14, the turning and moving positioning mechanism includes a horizontal movement mechanism, Up and down moving mechanism, clamping mechanism and rotating mechanism; described high-pressure air blowing mechanism comprises gas nozzle 6, gas nozzle direction adjustment structure; described horizontal moving mechanism, up and down moving mechanism, clamping mechanism, rotating mechanism, vibrating mechanism 8, gas The mouth direction adjustment structure and the movement of the product conveying mechanism are all controlled by the automatic control system.

[0016] The horizontal movement mechanism includes a pneumatic slide table 1 and a guide rail mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com