Crawler type pineapple picking machine

A picking machine and crawler-type technology, applied in the field of crawler-type pineapple picking machines, can solve the problems of increasing output, unable to keep up with picking efficiency, and achieve the effect of reducing economic problems, improving picking quality and efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

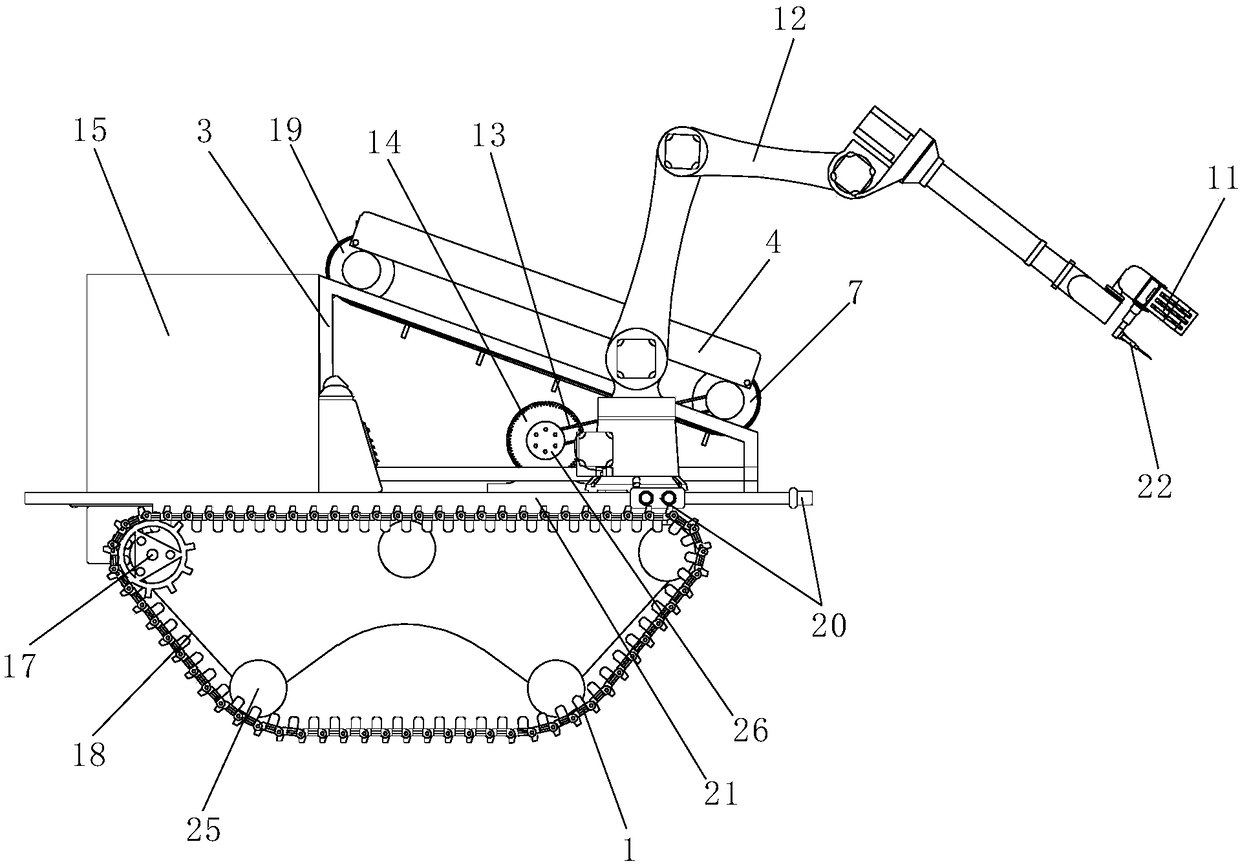

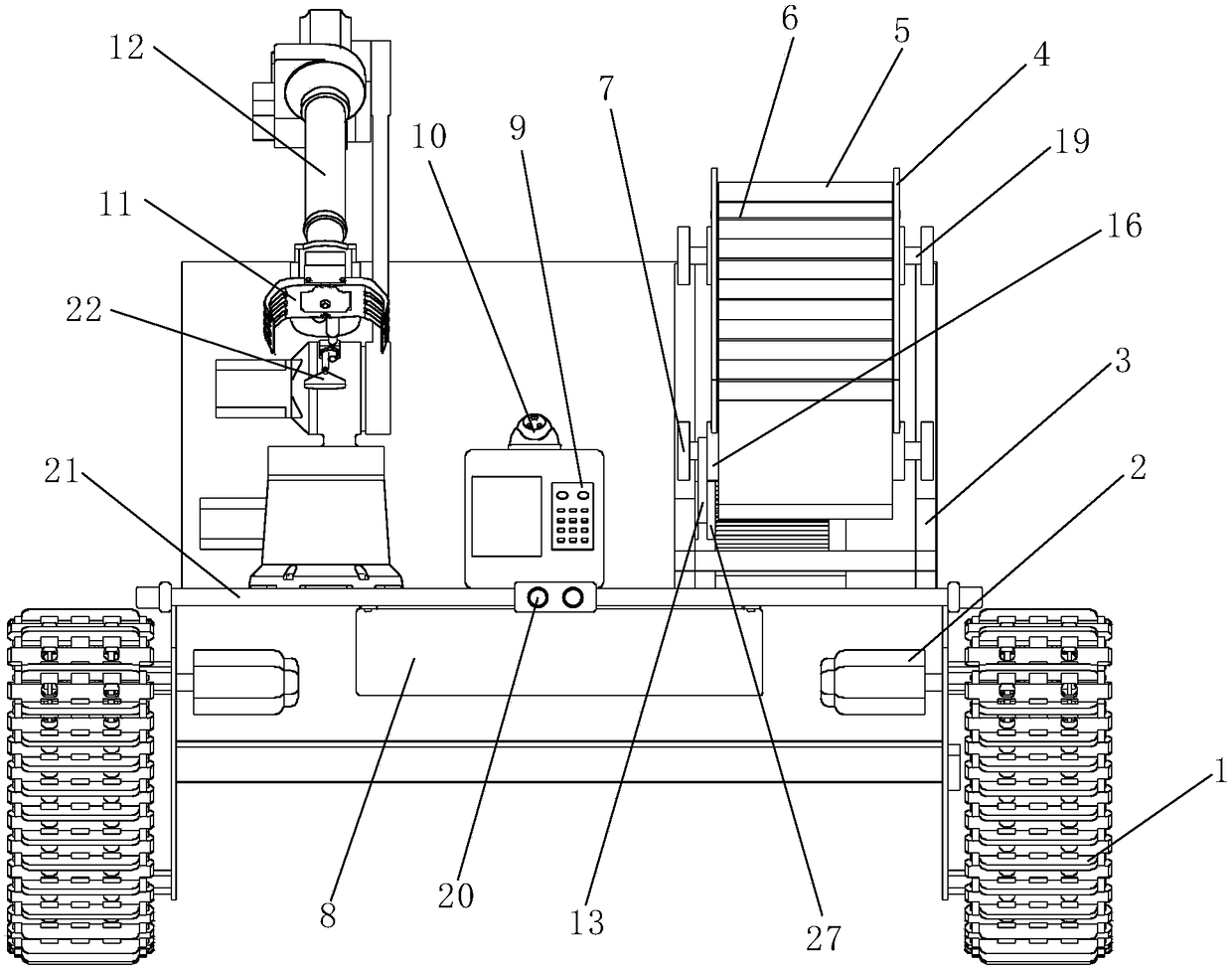

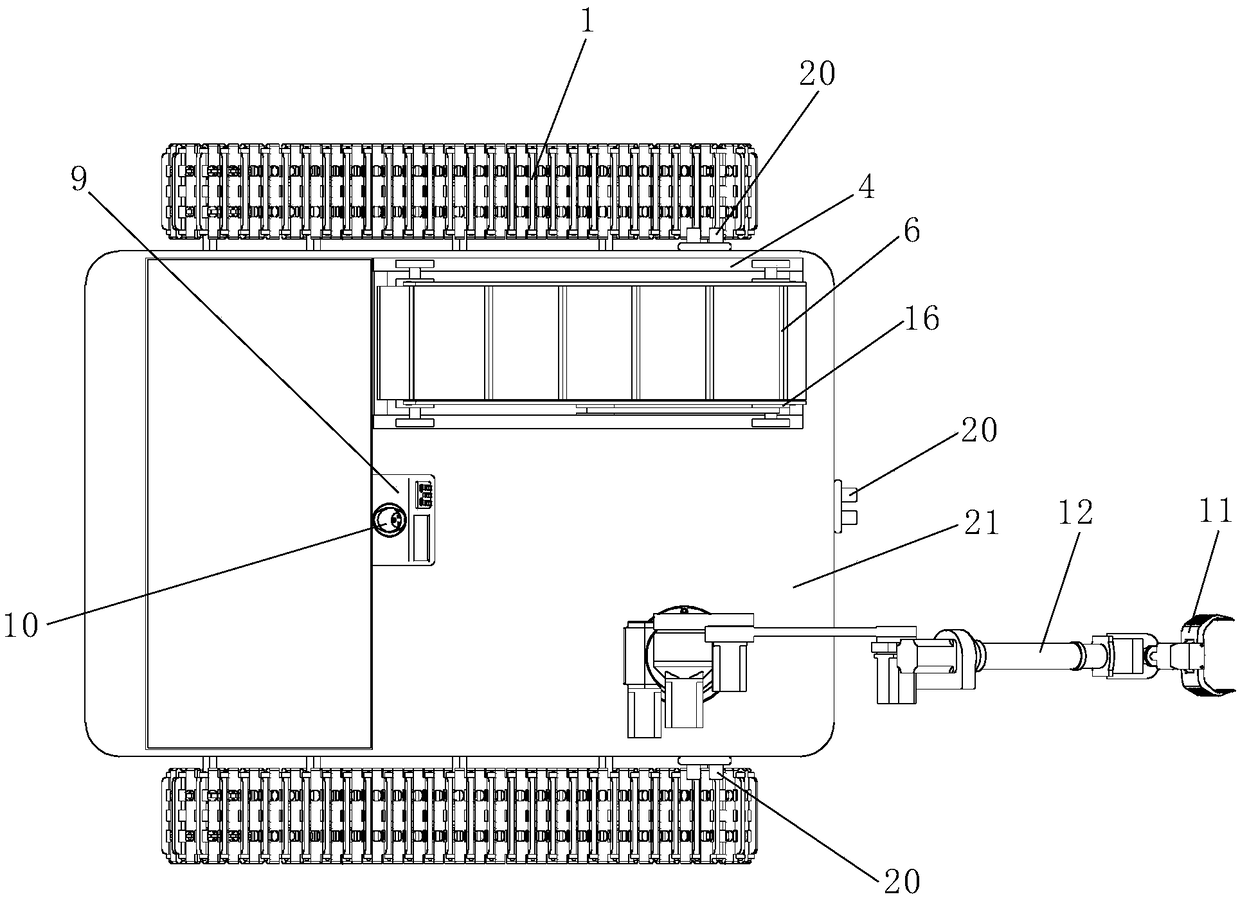

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 8 As shown, the present invention comprises car body 21, crawler belt running mechanism, mechanical arm picking device, pineapple transmission mechanism, pineapple collecting box 15, power supply lithium battery 8 and control box 9, and described crawler belt running mechanism is installed on the bottom of car body 21, The mechanical arm picking device is installed on the top right side of the car body 21, the pineapple transmission mechanism is installed on the top left side of the car body 21, and the pineapple collection box 15 and the control box 9 are installed behind the top of the car body 21. Side, described mechanical arm picking device, pineapple conveying mechanism and control box 9 are all positioned at the front of pineapple collecting box 15, and described control box 9 is positioned between described mechanical arm picking device and described pineapple conveying mechanism and is close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com