Production technique of removing kernel from the apricot and mechanical production chain

A production process and production line technology, which is applied in the fields of food processing and machinery manufacturing, can solve the problems of fresh fruit rot and deterioration, apricots intolerable to storage, and low operating efficiency, and achieve the effects of uniform size, improved food safety and hygiene quality, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

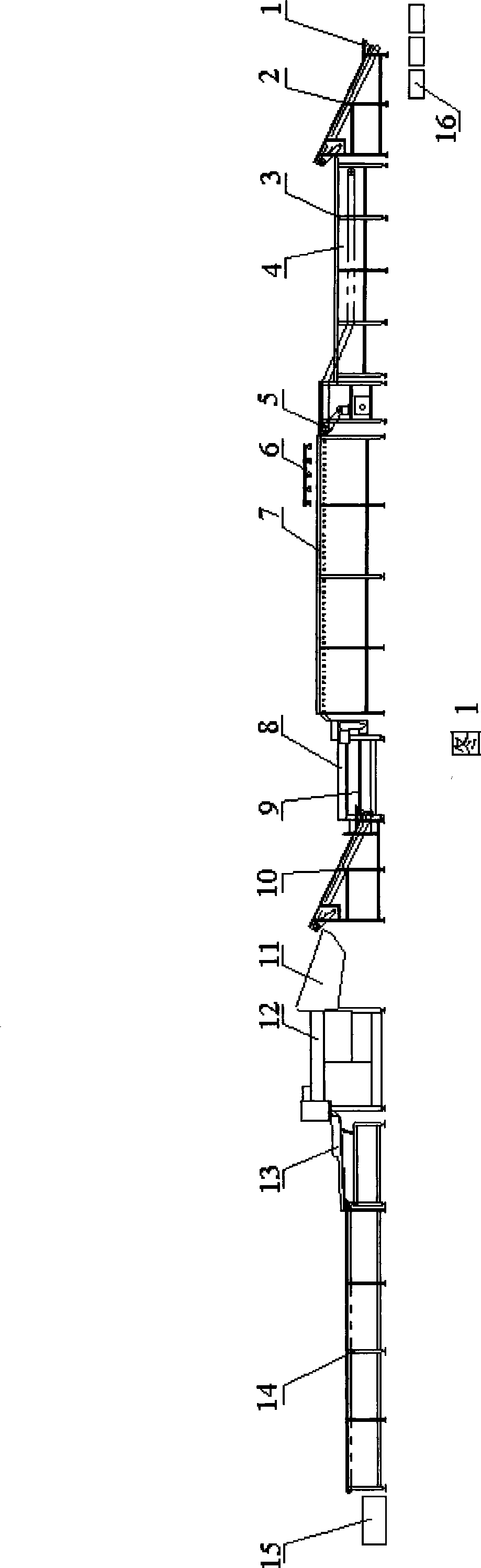

[0027] The apricot cutting and pitting production process of the present invention mainly includes bubble cleaning, high-pressure spray cleaning, fruit selection, grading, branch conveying, automatic orientation, cutting and pitting, separation of pulp and core, turning over and pulp selection process. The following is a detailed introduction to each process in conjunction with the accompanying drawings:

[0028] A) Bubble cleaning: the lifting conveyor transports the apricots to the cleaning tank equipped with a bubble generating device, and tap water is injected into the cleaning tank. Floats such as leaves in the fruit can overflow from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning;

[0029] B) Spray cleaning; the conveyor belt of the washing machine sends the apricots to the roller-type fruit sorting machine. There is a spray device above the type fruit sorting machine, and the high-pressure water is sprayed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com