Bedspread embroidery machine

An embroidery machine and frame technology, applied in the field of flat embroidery, can solve the problems of not being able to adapt to the actual production situation and waste of enterprises, and achieve the effect of simple operation, easy learning, and investment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

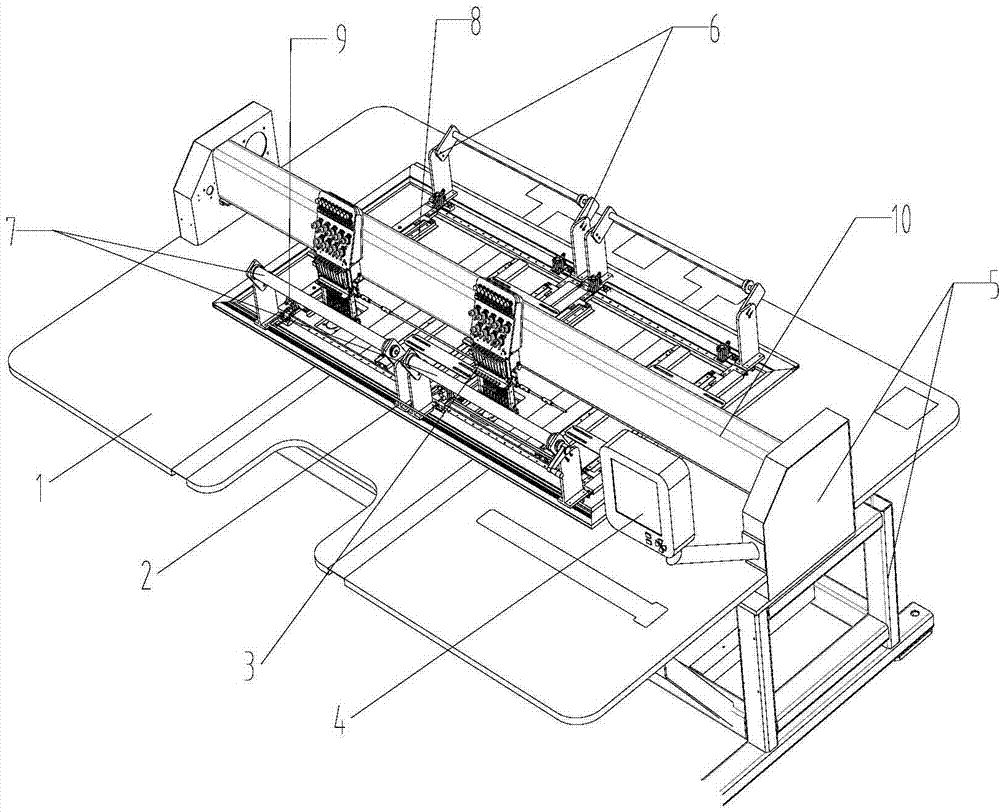

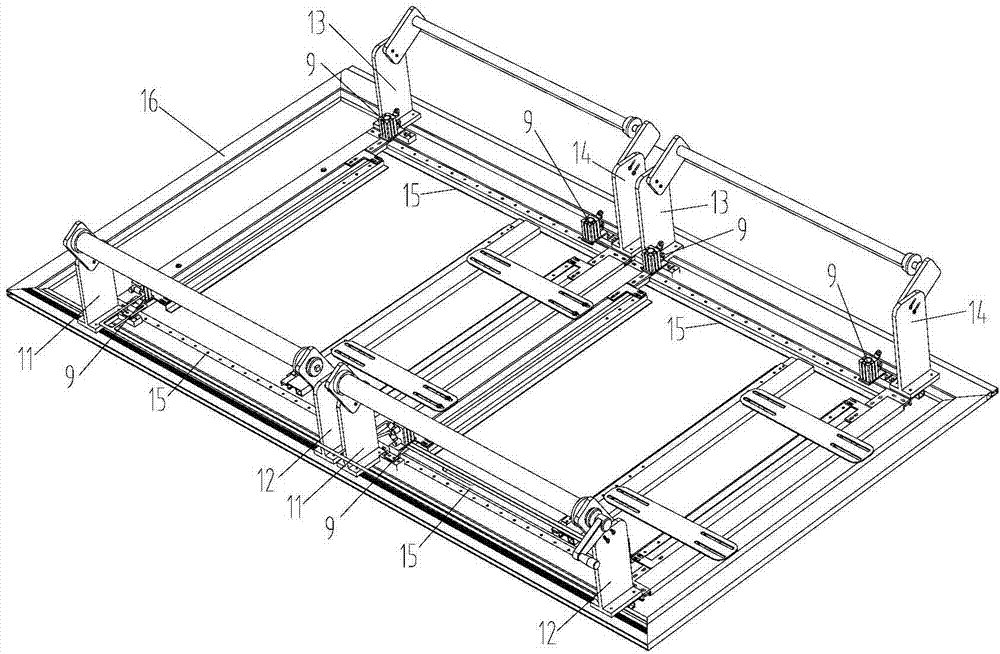

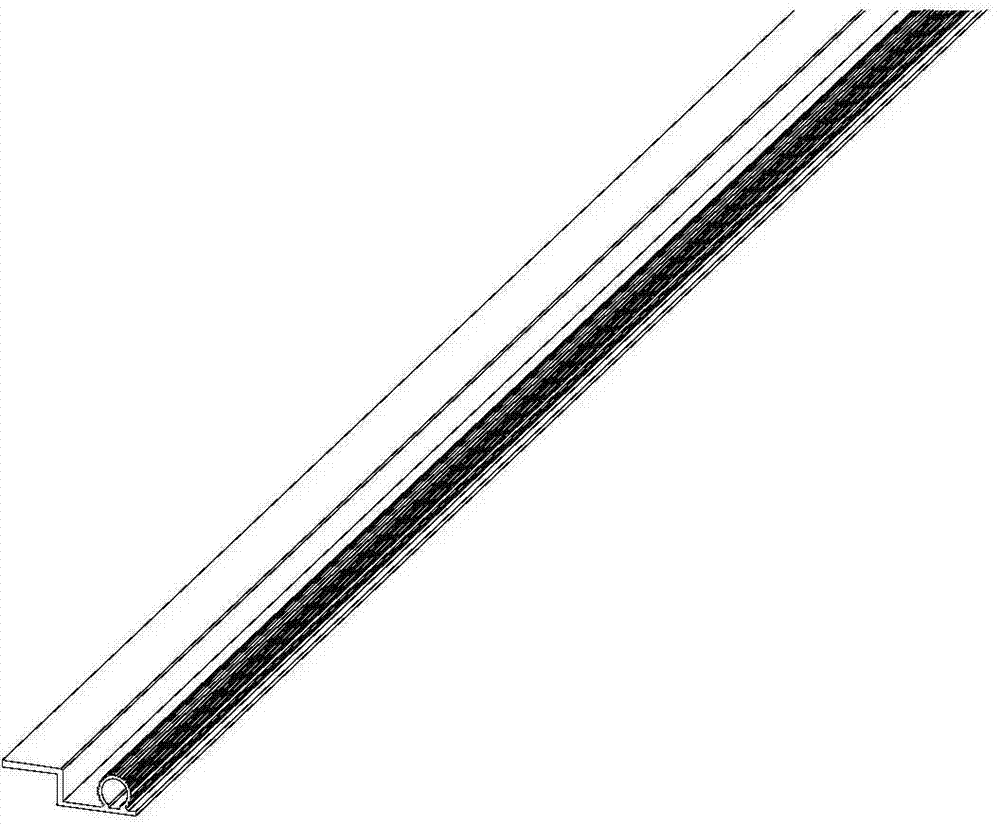

[0014] The present invention includes a frame (5) and a table (1) installed on the frame (5). The table (1) is equipped with a pneumatic embroidery frame (2), and the lower part of the pneumatic embroidery frame (2) is a flat embroidery frame. Embroidery frame (16), the upper part has feeding device (6), material receiving device (7), guiding device (8), pneumatic pressing mechanism (9), upper and lower parts pass connecting plate a (11), connecting plate b (12 ), connecting plate c(13), and connecting plate d(14) are fixed together with screws, so that the embroidery will not move due to the loose connection of the two embroidery frames during the embroidery process. When performing bed curtain embroidery, Put the bed curtain roll in the feeding device (6), then pull the movable end of the bed curtain roll through the pressure rod of the pneumatic pressing mechanism (9), guide device (8), and pass through the girder (10), pneumatic pressing The depression bar of mechanism (9)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com