Screw installation automatic production line

An automatic production line and screw technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of rework and scrapped semi-finished products, the number of full boxes is insufficient or exceeded, and hidden dangers to operator safety, etc., to achieve a simple structure , save space, take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0046] The present invention will be described in detail below with reference to the accompanying drawings and examples.

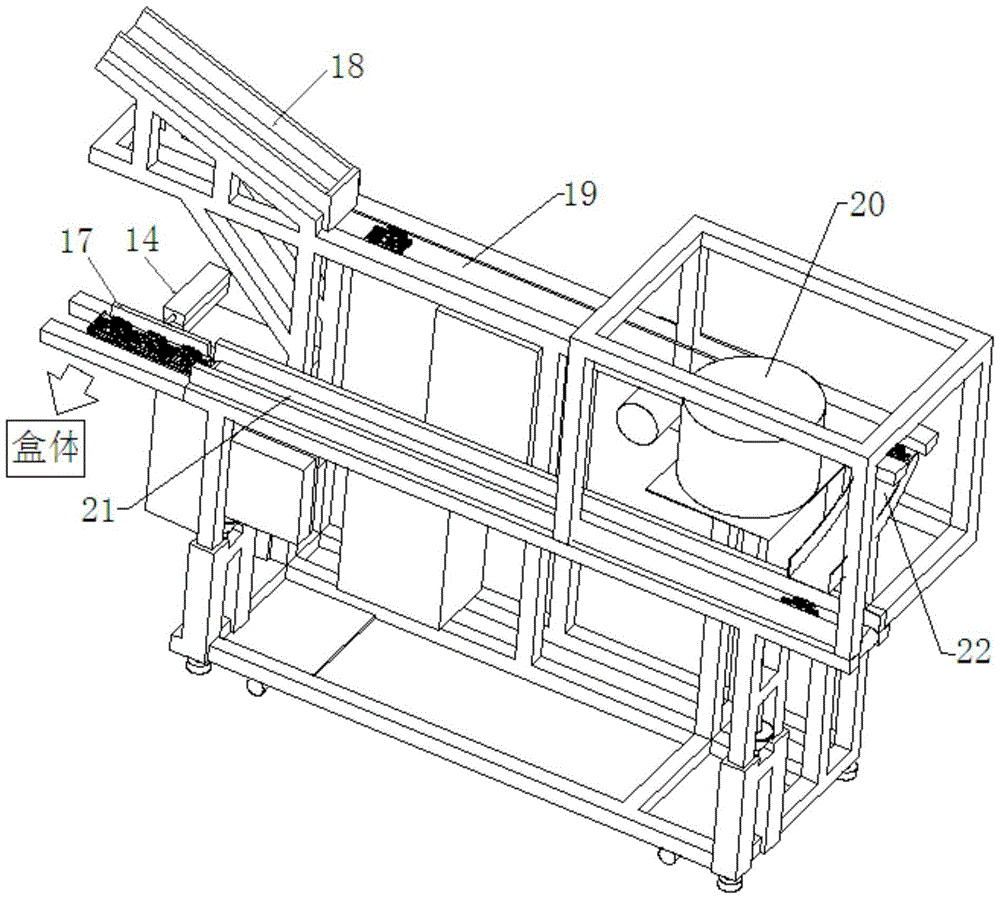

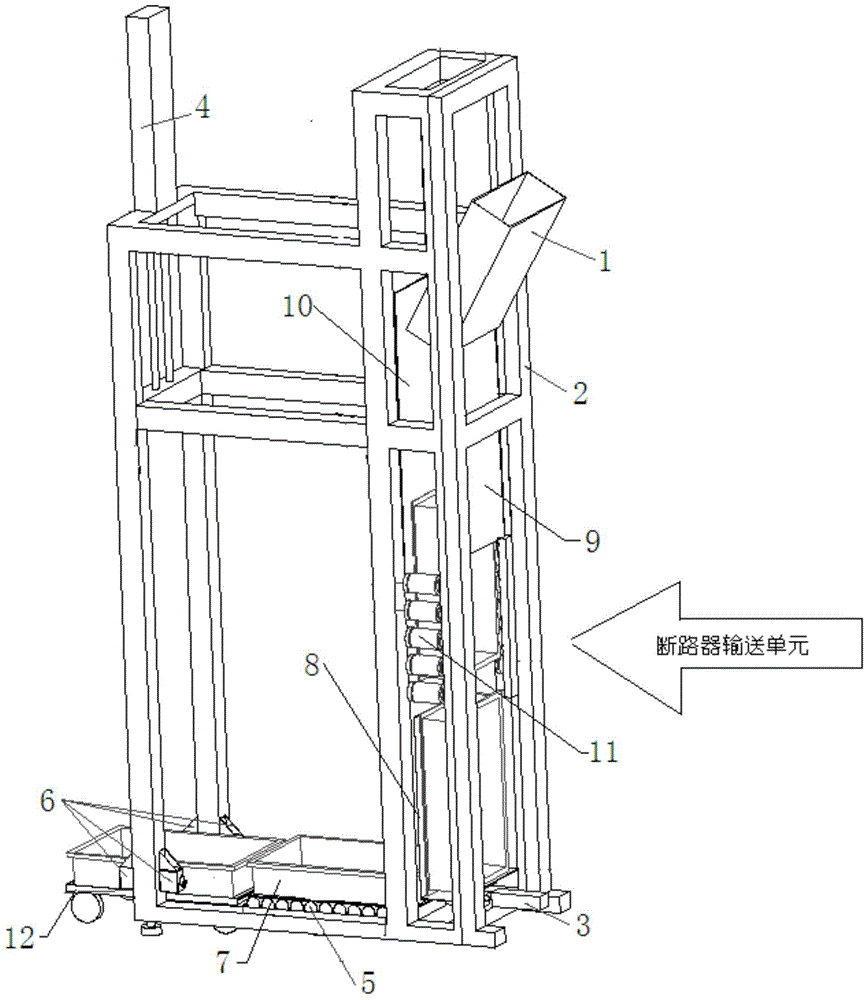

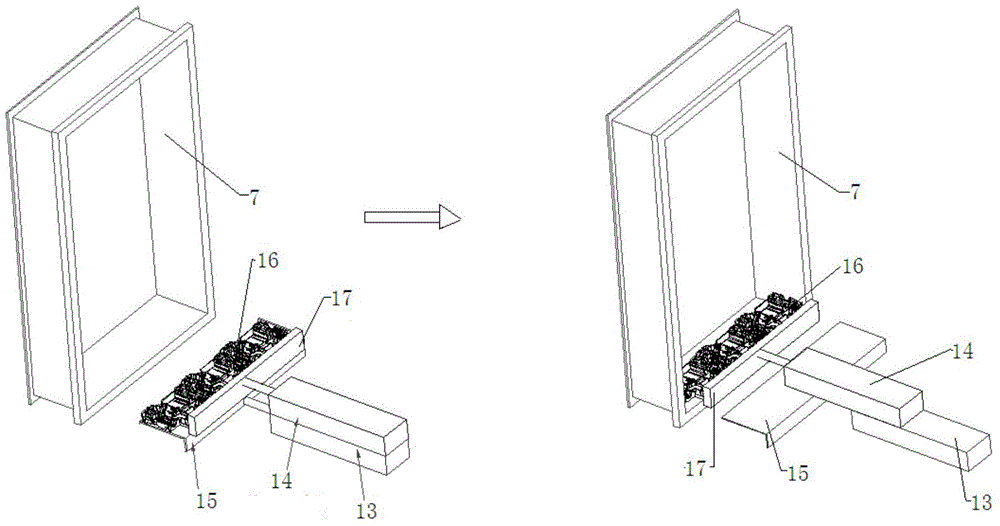

[0047] Such as Figure 1-17As shown, an automatic screw installation production line includes a circuit breaker case conveying device, a thermally adjustable screw conveying device and a thermally adjustable screw installation jig, the circuit breaker case conveying device, a thermally adjustable screw conveying device and a thermally adjustable screw installation The jigs are all intermittent, and the heat-adjusting screw conveying device is arranged on one side of the circuit breaker housing conveying device, and the output end of the heat-adjusting screw conveying device is connected to the input end of the heat-adjusting screw installation jig. The bottom of the heat-adjusting screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com