An automatic packing mechanism for wine production line

An automatic packing and assembly line technology, applied in packaging and other directions, can solve problems such as affecting production efficiency, time-consuming, laborious, troublesome, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

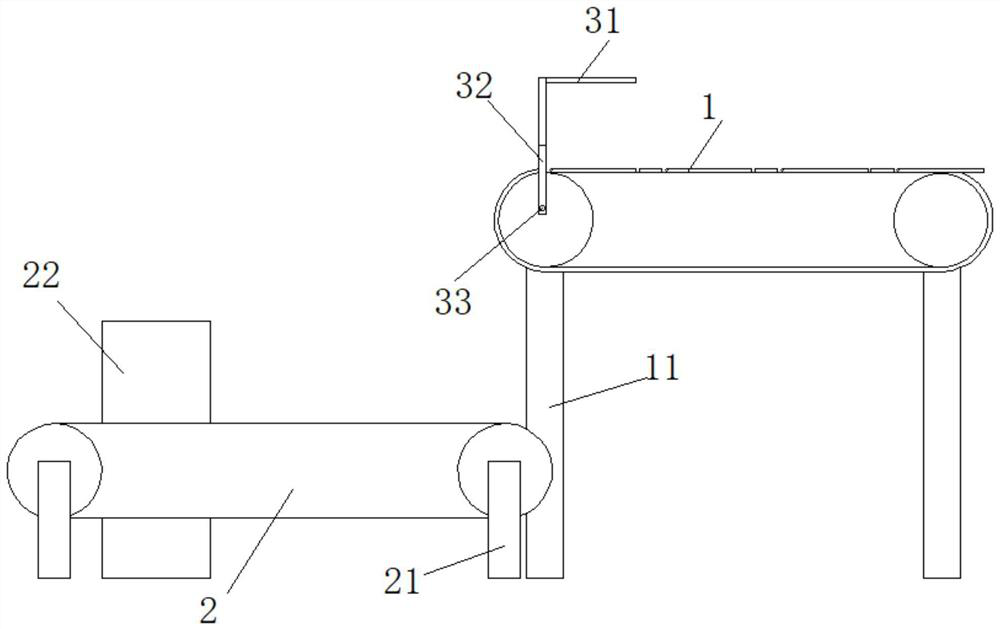

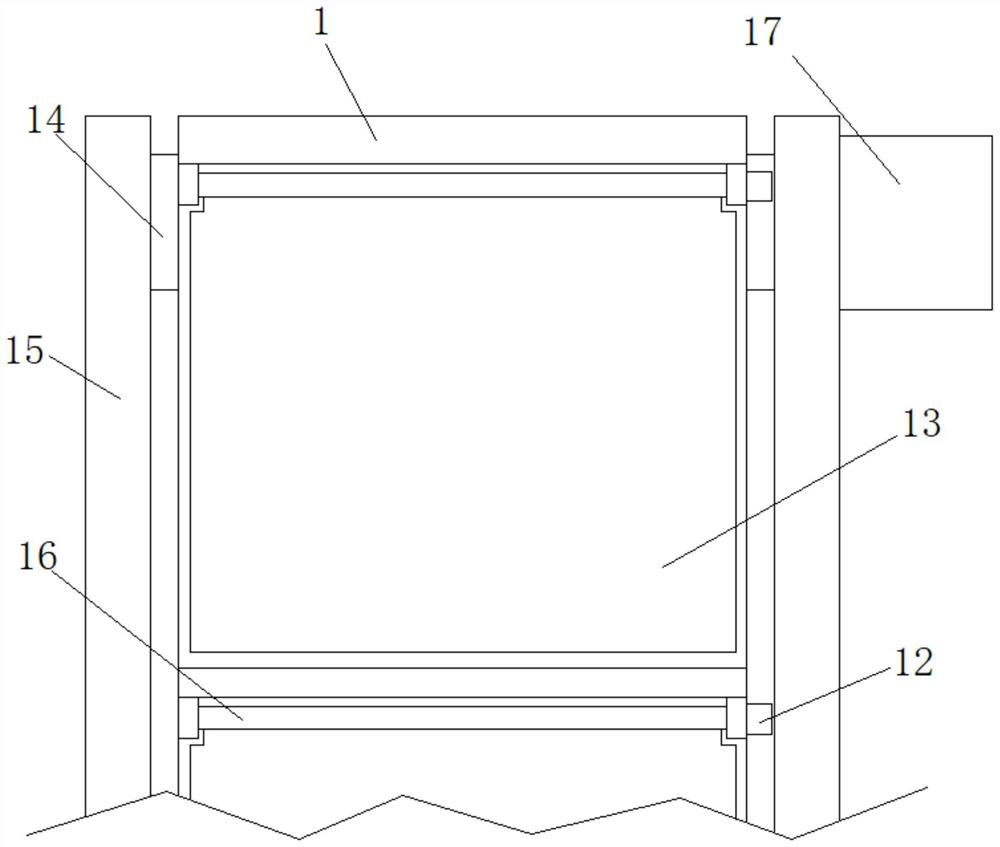

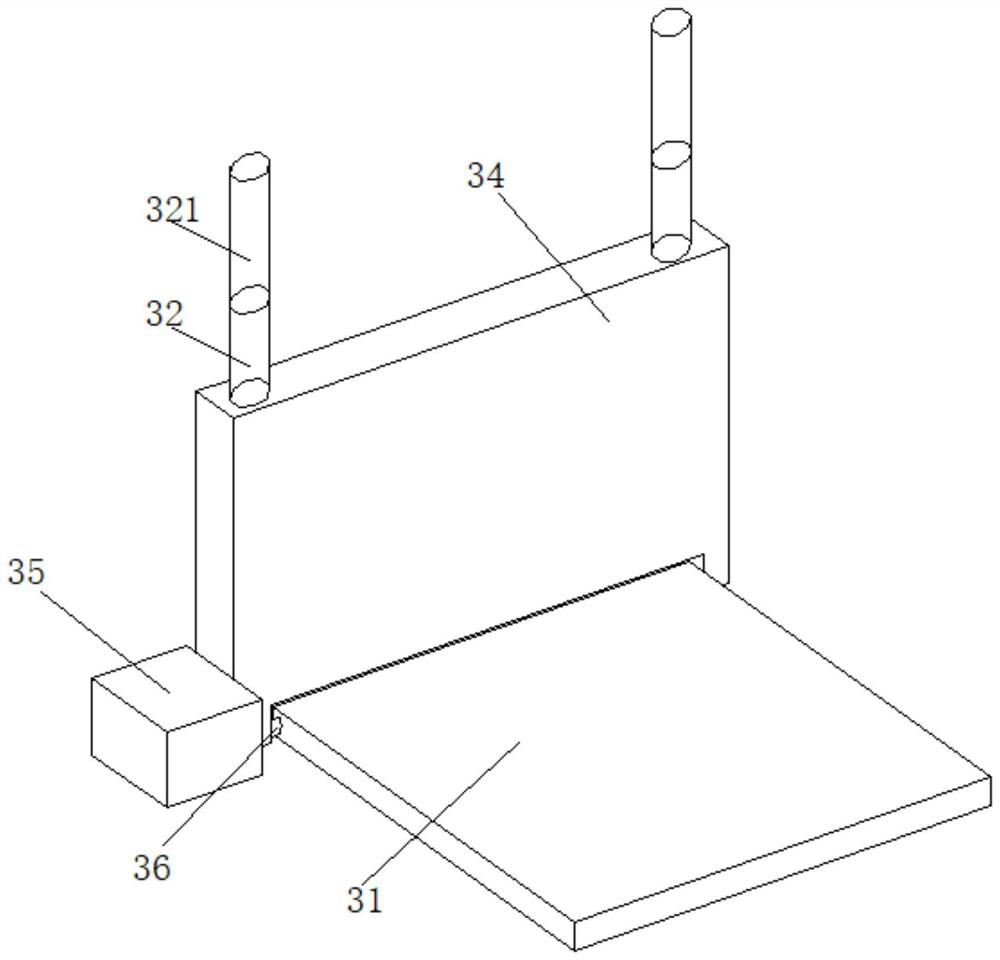

[0027] see Figure 1-5 , an automatic boxing mechanism for brewing assembly line production, comprising a first conveyor belt 1 and a second conveyor belt 2, the second conveyor belt 2 is located at the bottom of one end of the first conveyor belt 1, and is located between the second conveyor belt 2 The end of the first conveyor belt 1 on the side is provided with a packing mechanism, and the packing mechanism includes a first turning plate 13, a second turning plate 34 and a pressing plate 31, and there are multiple first turning plates 13, and The first turning plate 13 is evenly and rotatably connected to the surface of the first conveyor belt 1; the second turning plate 34 is rotatably arranged at the end of the first conveyor belt 1; the pressing plate 31 is connected to the second turning plate 34 side of the upper end.

[0028] Further, both sides of the first conveyor belt 1 are provided with symmetrically distributed conveyor frames 15, and the first conveyor belt 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com