Automatic boxing method and device for bottles

An automatic boxing and bottle body technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems of insufficient moving space for the grabbing device and bottle body dumping, so as to prevent the bottle body from tipping over, avoid dumping damage, and avoid The effect of downtime finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment describes a bottle body automatic packing method, which includes the following steps:

[0054] In the first step, the blocking device moves along the conveying direction from the front side of the feeding area, and at the same time, the conveying device moves the bottle body along the conveying direction until the blocking structure of the blocking device moves to the front side of the area to be packed; The moving speed ≤ the transmission speed of the transmission device; the blocking structure is in the down state, and the blocking device is located on the front side of the bottle body to fit the bottle body to prevent the bottle body from tipping over during the movement;

[0055] In the second step, the blocking device moves the blocking structure upward, and the front side of the area to be packed is provided with a baffle to block the movement of the bottle body; then the blocking device moves to the front side of the feeding area;

[0056] ...

Embodiment 2

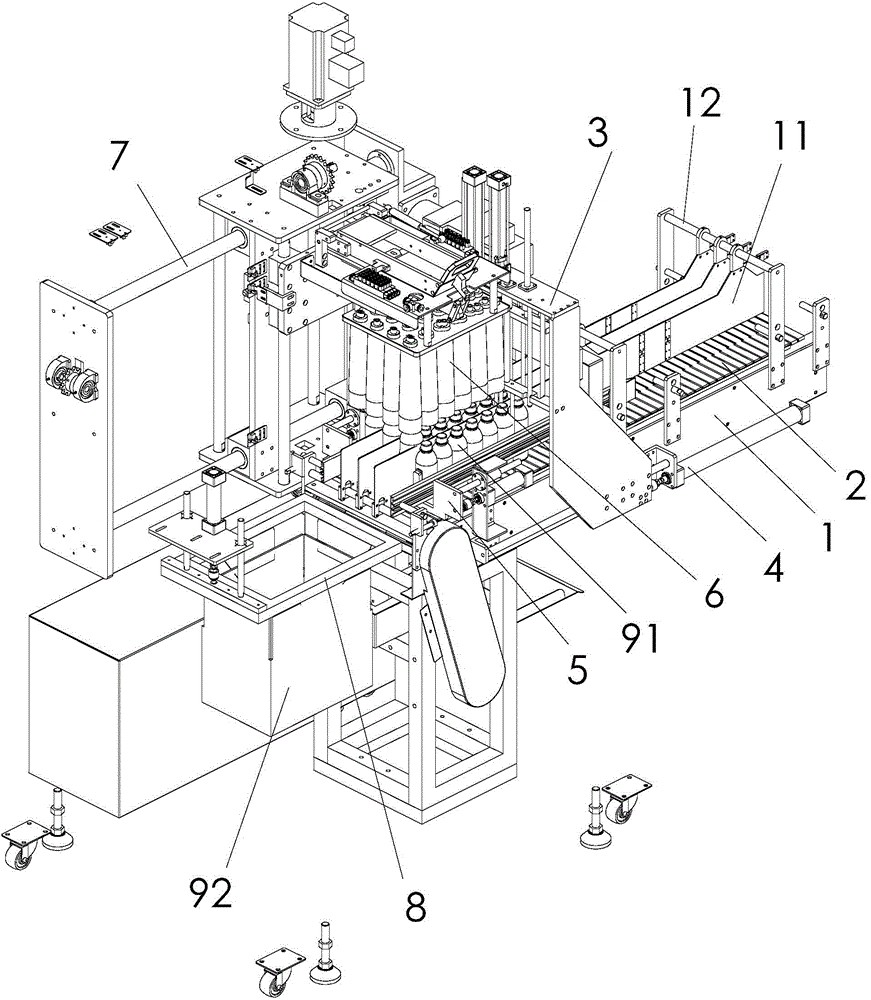

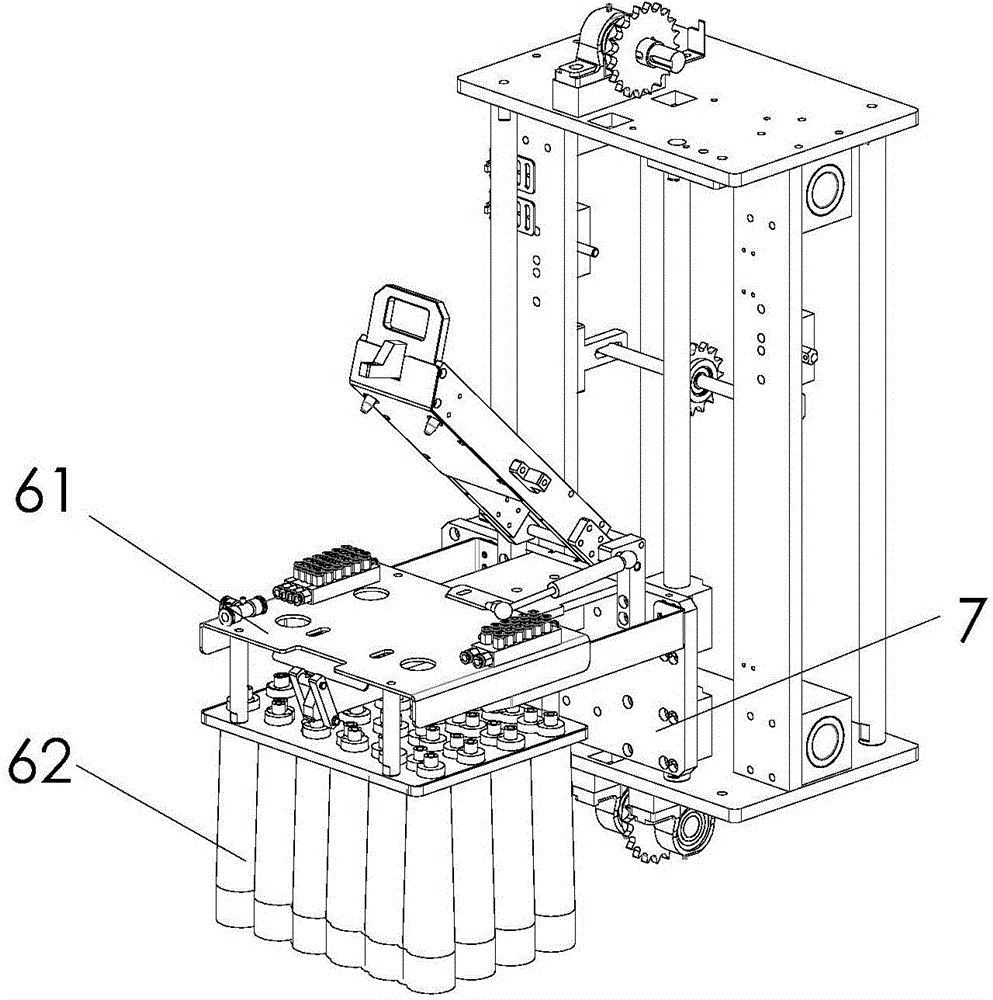

[0064] This embodiment describes an automatic bottle packing equipment, the structure of which is as follows figure 1 As shown, the apparatus comprises a frame 1, a transfer device 2, a blocking device 3, a shutter 5, a gripping device 6 and a control device.

[0065] The conveying device 2 is used to move the bottle body along the conveying direction; the conveying device 2 is arranged on the frame 1;

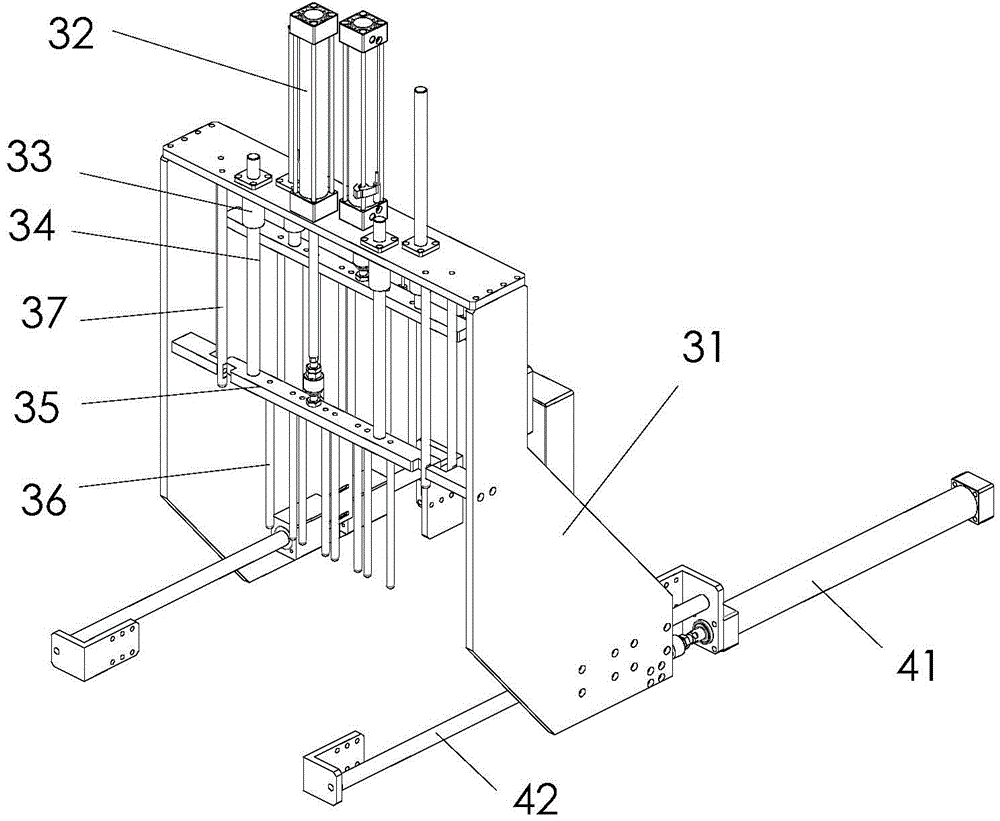

[0066] The blocking device 3 includes a blocking base frame 31 and at least one set of blocking components; the blocking base frame 31 and the frame 1 are connected by a blocking translation mechanism 4, so as to realize the connection between the blocking device 3 on the front side of the loading area and the area to be packed. The blocking assembly includes a blocking longitudinal driving mechanism and a blocking structure; the blocking structure is arranged on the blocking base frame 31 through the blocking longitudinal driving mechanism; the blocking structure is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com