Automatic gift box lining plate boxing machine and method

A case packing machine and liner technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of inability to complete the placement of flanging liners, the inability to complete liner forming and folding, etc., to improve workshop production efficiency , Reliable and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

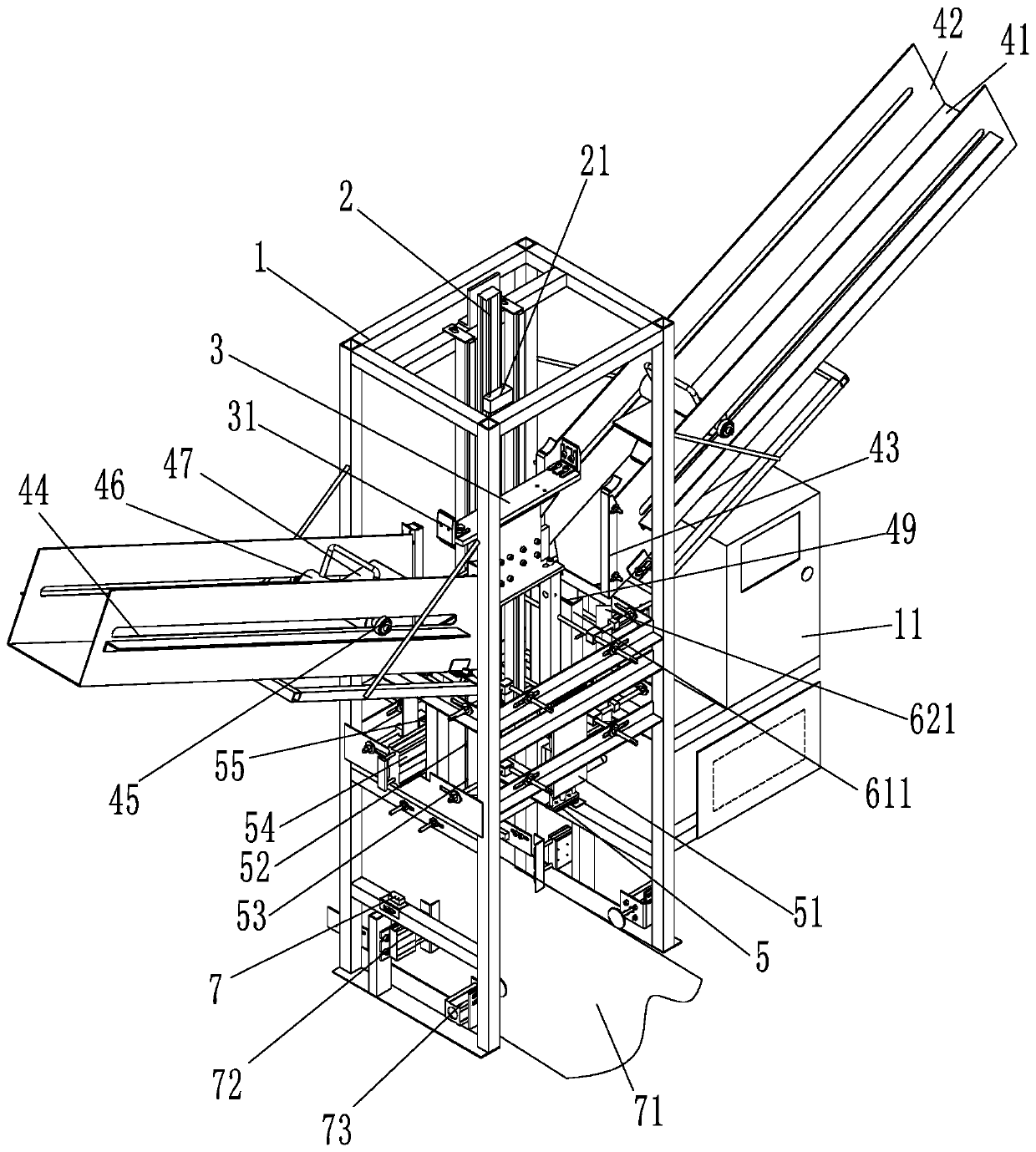

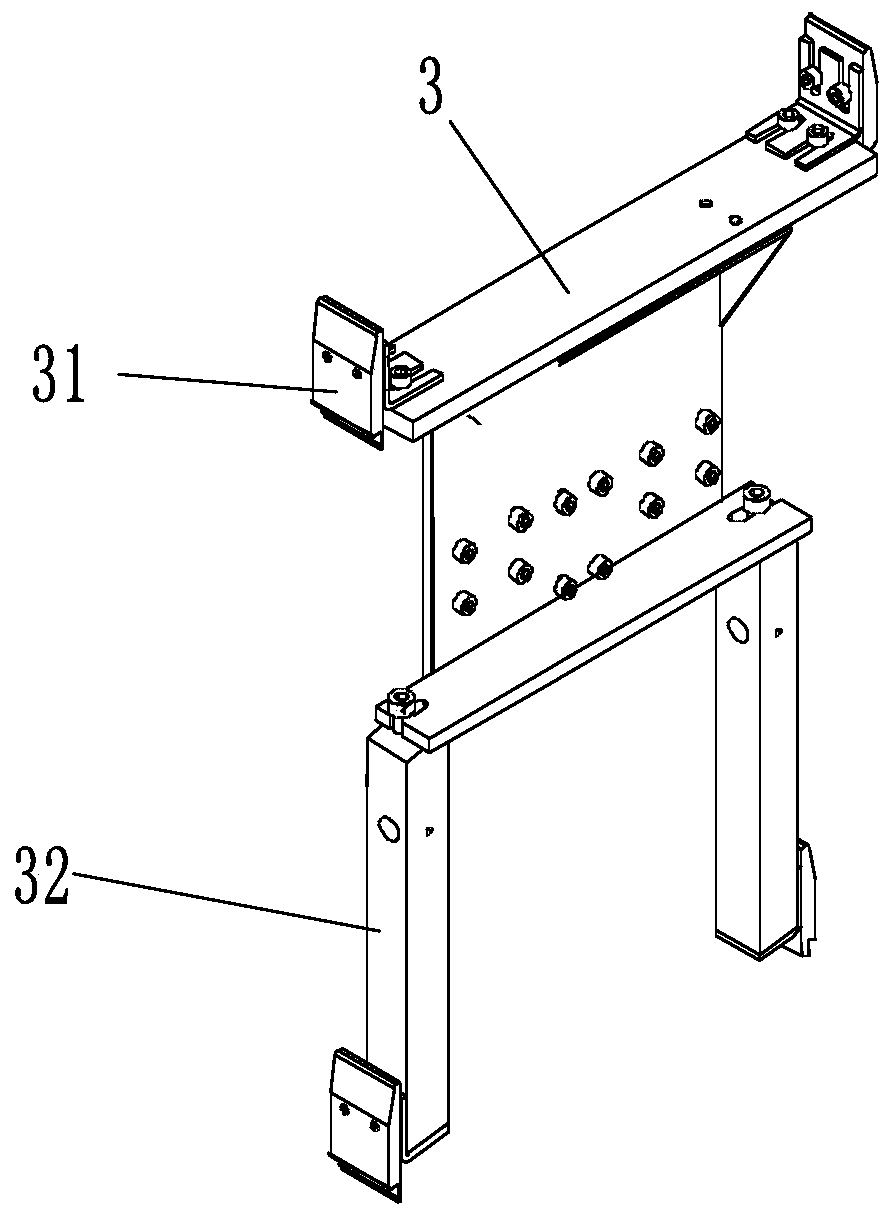

[0032] Figure 1 to Figure 3 Among them, an automatic case packing machine for lining boards of gift boxes, which is used for installing the lining boards 9 and the box body, includes a frame 1, and a power distribution cabinet 11 is arranged on the outside of the frame 1. Image 6 Among them, the liner 9 is installed on the opposite ends of the box, and the end of the liner 9 is provided with the main body of the vertical liner 9 and the flanges 91 at both ends of the box. The frame 1 is provided with the liner 9 blanking module and the liner 9 forming module arranged sequentially from top to bottom, and the bottom of the frame 1 is provided with a carton 8 that can transport the box to the liner 9 blanking module. module; the liner 9 blanking module includes a silo 4 for placing the liner 9 and a paper sheet mechanism. The support frame connected with the parts, the hopper tank 4 is set downward from the outside of the frame 1 towards the direction of the frame 1, and the sil...

Embodiment 2

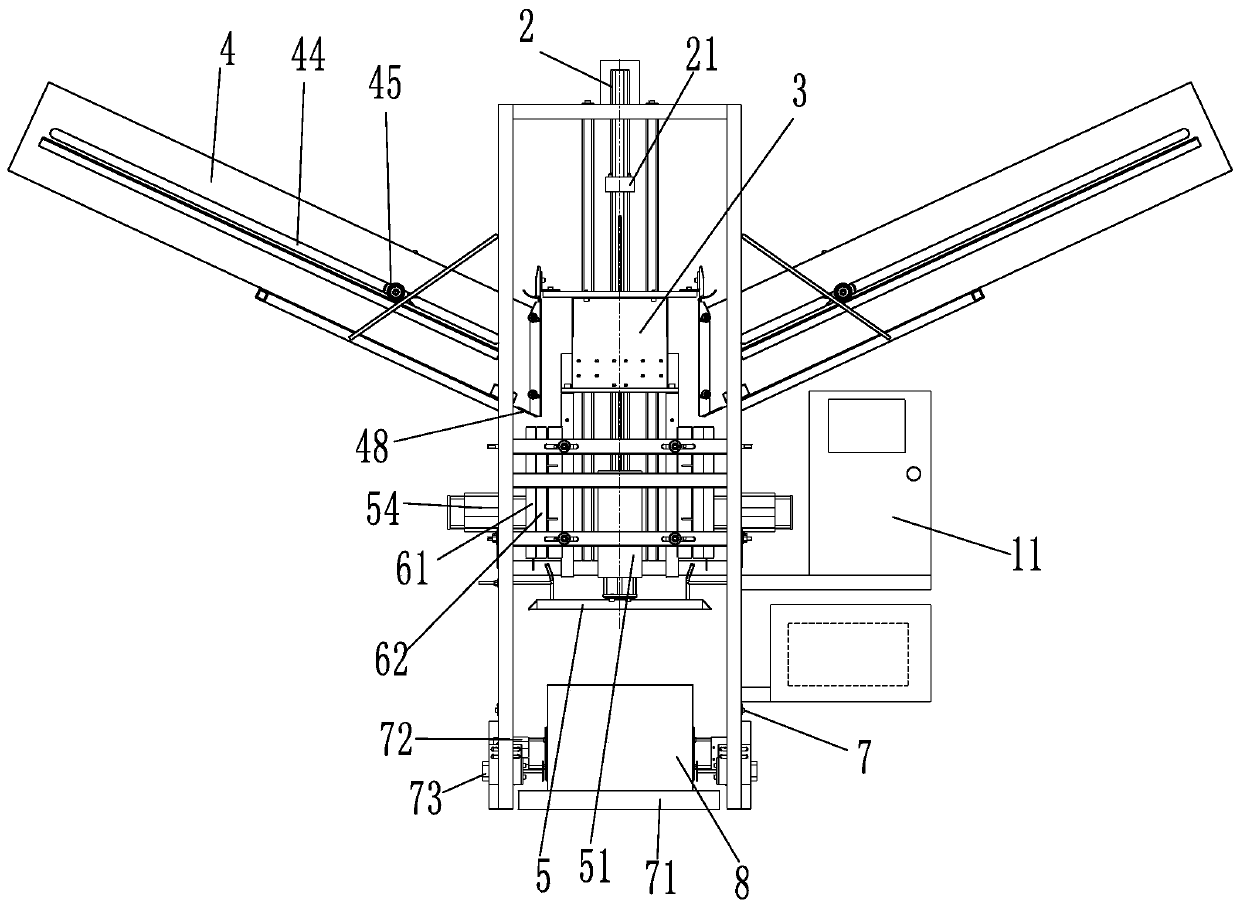

[0035] Figure 4 The illustrated embodiment is compatible with figure 1 The embodiment shown differs in the application of a different configuration of the silo tank 4 . The feeding bin groove 4 is provided with two symmetrical ones on both sides of the frame 1, and the connection line of the two feeding bin grooves 4 is vertical to the conveying direction of the carton 8 conveying device; Bottom plate 41 both sides and two limit plates 42 of vertical base plate 41, silo tank 4 is horizontally arranged, and feed bin tank outlet 48 is positioned at the bottom plate 41 of silo tank 4 toward one end of frame 1, and limit plate 42 faces frame 1 One end of one end is provided with the baffle plate 43 that prevents liner plate 9 from slipping out; The feed bin groove 4 is provided with the screw rod slider mechanism 402 driven by motor 401 respectively on the outside of two limit plates 42, and feed bin groove 4 is arranged on two limit plates The outer sides of 42 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com