Firework structure

A firework structure and firework technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as explosive tubes, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

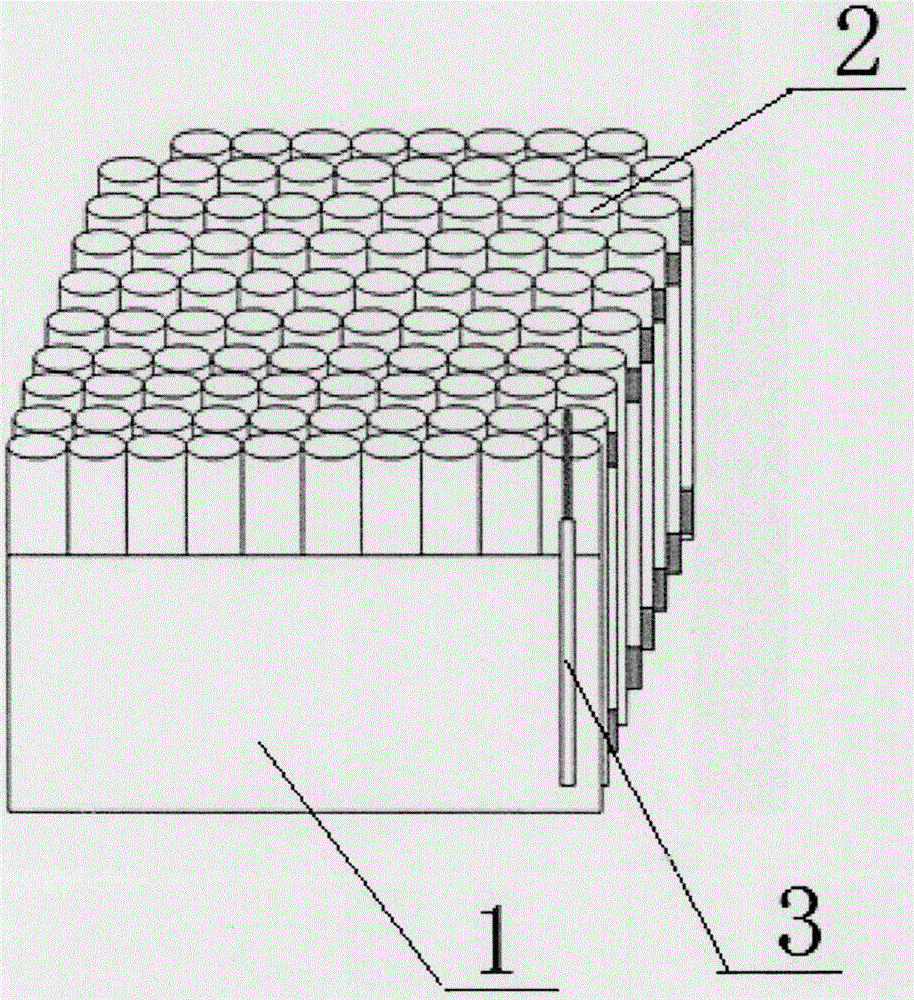

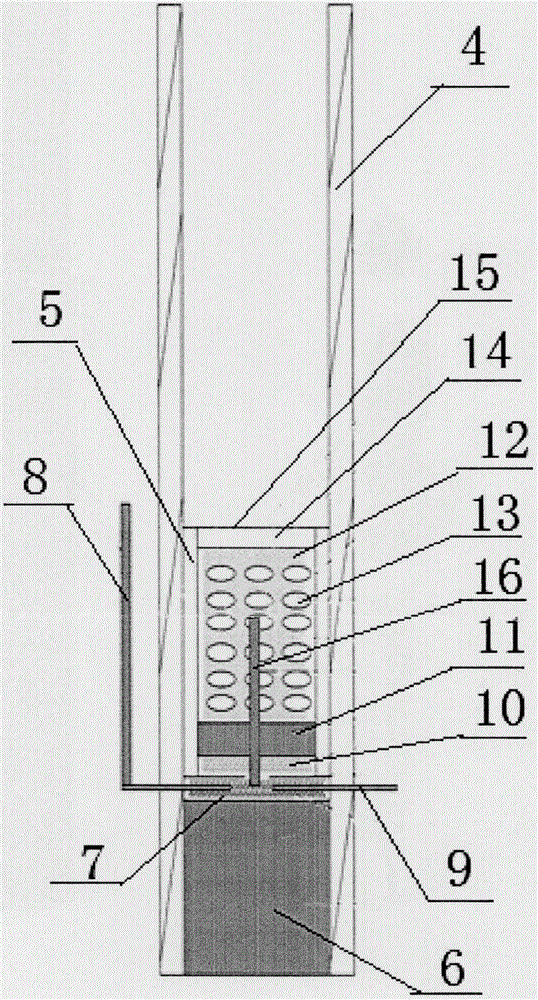

[0015] Combine figure 1 The firework structure shown includes an outer box 1. Ten rows of fireworks display tubes 2 are arranged in the outer box 1, of which ten fireworks display tubes 2 are arranged in each row from one to nine rows, and eight fireworks display tubes are arranged in the tenth row. The fireworks display tube 2 is provided with a firework main ignition trigger 3 outside the outer box. The fireworks display tube 2 includes an outer tube 4 and an inner tube 5 arranged inside the outer tube. The bottom of the outer tube 4 is provided with a bottom mud 6 and a bottom mud 6 is provided above the bottom mud 6 Black propellant layer 7, one end of the black propellant layer 7 is connected to the ignition tube 8 of the firing tube, and the other end is provided with a flame transfer tube 9. Both the tube ignition tube 8 and the fire tube 9 lead to the periphery of the outer tube 4, and the black powder layer 7 The inner tube 5 is provided on the eye-piercing cardboard, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com