Firework paper tube, sealing mold and sealing method for firework paper tube, and effect tube of firework paper tube

A technology for sealing molds and effect cylinders, which is used in fireworks, offensive equipment, weapon types, etc., can solve the problems of destroying ecological balance, destroying the environment, soil erosion, etc., to improve production efficiency, simplify production processes, and reduce transportation weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

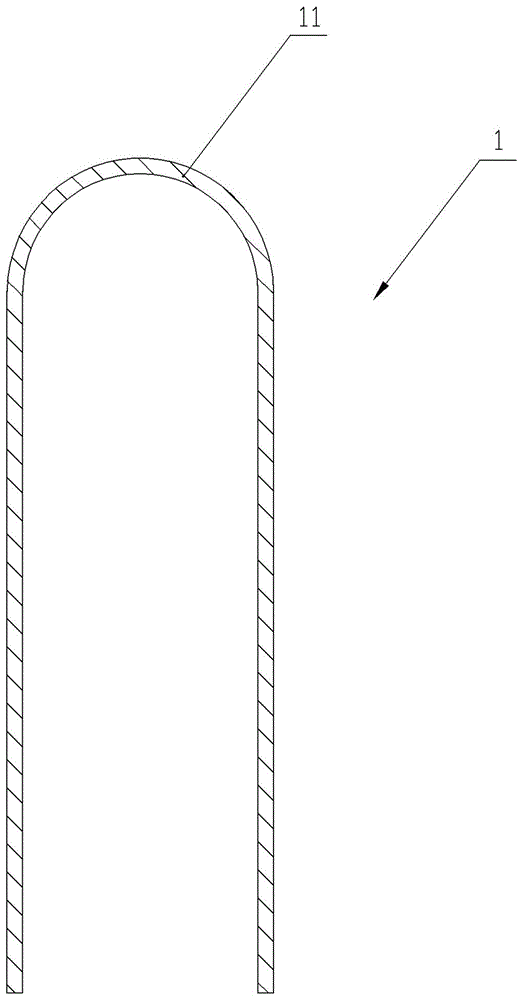

[0035] Such as figure 1 As shown, one end of the firework paper tube 1 provided in this embodiment is an opening, and the other end is a bottom seal 11 formed by extruding the cylinder itself. The bottom seal 11 is arc-shaped, and the opening end is a flat mouth. While ensuring the convenience of production, the bottom seal 11 can effectively replace the overcooked mud that needs to be pressed in the traditional process, eliminating the step of pressing yellow mud, simplifying the production process, reducing production costs, and being environmentally friendly without using yellow mud , to avoid soil erosion, reduce the waste residue after discharge, which is beneficial to environmental protection.

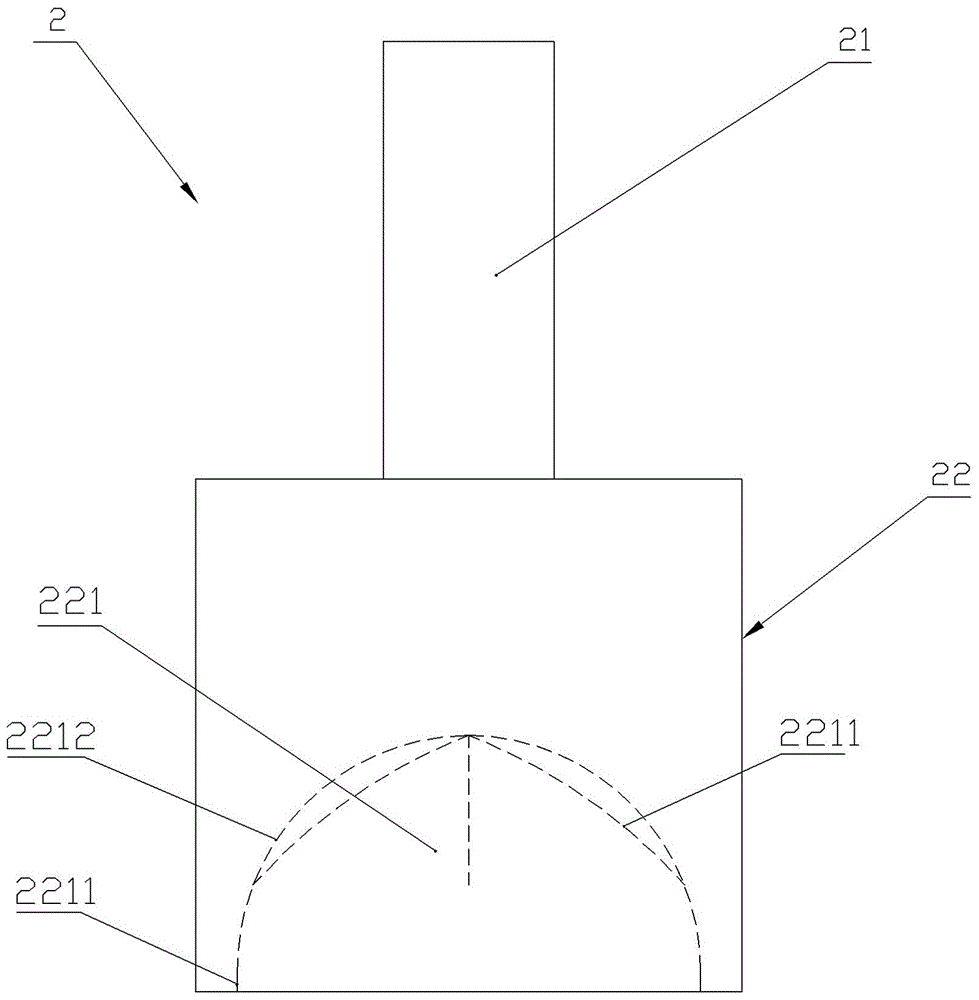

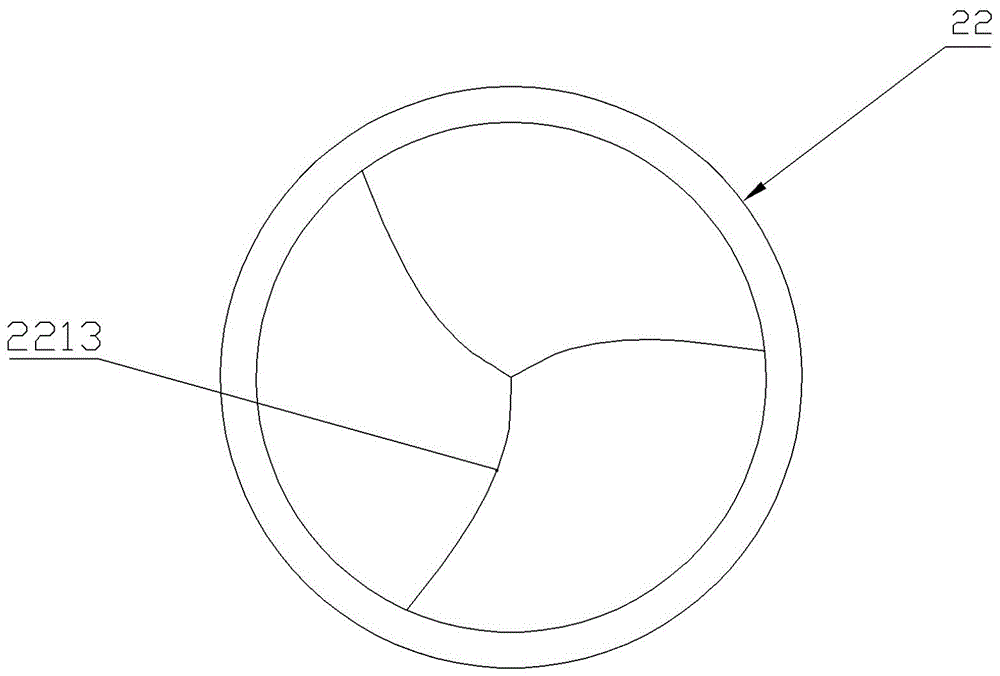

[0036] Such as figure 2 As shown in -4, the sealing mold provided by this embodiment includes a female mold 2 and a male mold 3, the female mold 2 is an integral part, and includes connecting rods 21 and sealing seats 22 arranged up and down, connecting rods 21 and sealing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com