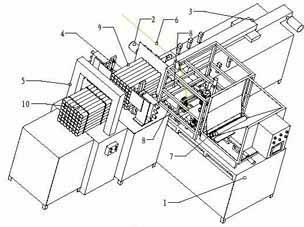

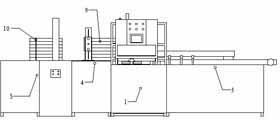

Automatic assembly machine set of fireworks

An automatic assembly and fireworks technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of multiple transmission links, reduced mechanism rigidity, large errors, etc., and achieve reliable and stable operation, high degree of automation, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

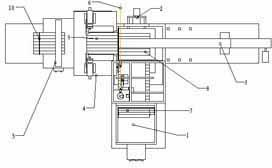

[0035] After the present invention is mechanically assembled and electrically connected according to the above-mentioned principle and scheme, the program is downloaded to the PLC in the control box 1-2, the power supply and the gas source are connected, and the cylinder body 7 is ready for the hopper 1-3; 6Introduce the lead wire and turn the pulley 1-7, and then start production.

[0036] one, Preparation: (1) Parameter setting of the control box 1-2, on the man-machine interface of the control box 1-2, ①according to the diameter and output of the cylinder 7, set the pushing distance and speed of the horizontal pushing mechanism 1-5 , acceleration and deceleration, and cylinder pushing cycle; ② According to the output, the diameter of the cylinder 7, the number of cylinders 7 in the cylinder row 8, the drilling depth, and the motion curve of the cylinder row 8, set the punching and inserting mechanism 1-6 The speed, acceleration and deceleration of punching and insertion, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com