Firework coiling machine

A reel machine and fireworks technology, applied in pyrotechnics, cardboard winding products, offensive equipment, etc., can solve the problems of hidden product quality, high production cost, easy moisture and mildew, etc., and achieve low water content, hardness and strength The effect of reducing and reducing the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

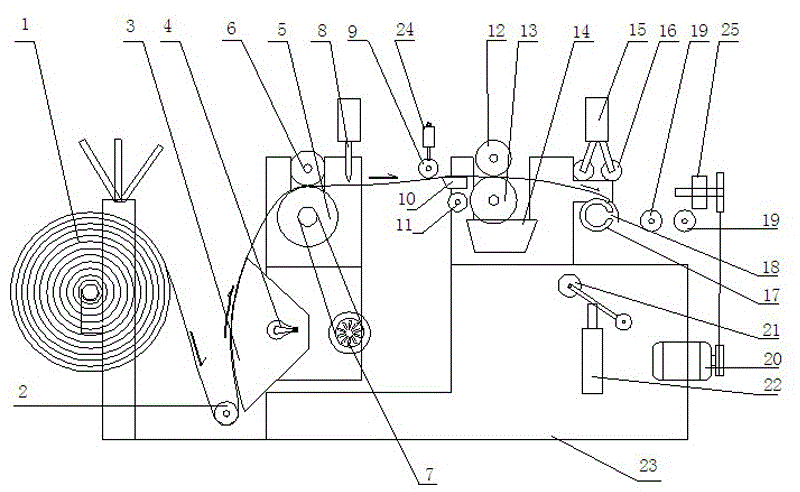

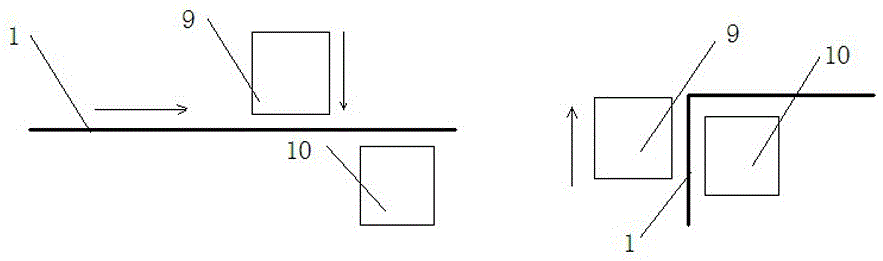

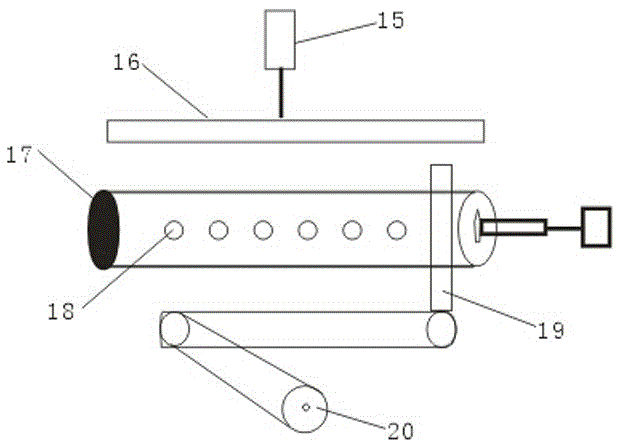

[0020] Example 1 Refer to figure 1 , figure 2 and image 3 ,Such as figure 1 , figure 2 , image 3 As shown, the fireworks reel machine of the present invention includes a paper heating mechanism, a paper feeding mechanism, a paper cutting mechanism, a paper shaping mechanism, a gluing mechanism, a reel mechanism, a bobbin cutting mechanism, and a bobbin unwinding mechanism installed on the frame 23 in sequence. , each mechanism of the fireworks reel machine is connected with the numerical control device of the main engine.

[0021] The roll paper 1 is arranged at the front end of the frame 23, and the head of the roll paper 1 is transported to the middle of the driving wheel 5 and the driven wheel 6 of the paper feeding mechanism through the transmission shaft 2 and the driving belt 3 of the paper heating mechanism. The driving wheel 5 and the motor 7 is connected, and after the motor 7 is started, the driving wheel 5 and the driven wheel 6 hold the roll paper 1 and ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com