Automatic pyrotechnic composition charging system

A charging system and pyrotechnic powder technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as safety accidents, low production efficiency of manual charging, unstable production quality of cartridges, etc., and achieve strong upgrading and upgrading The effect of promoting replacement and improving safety and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

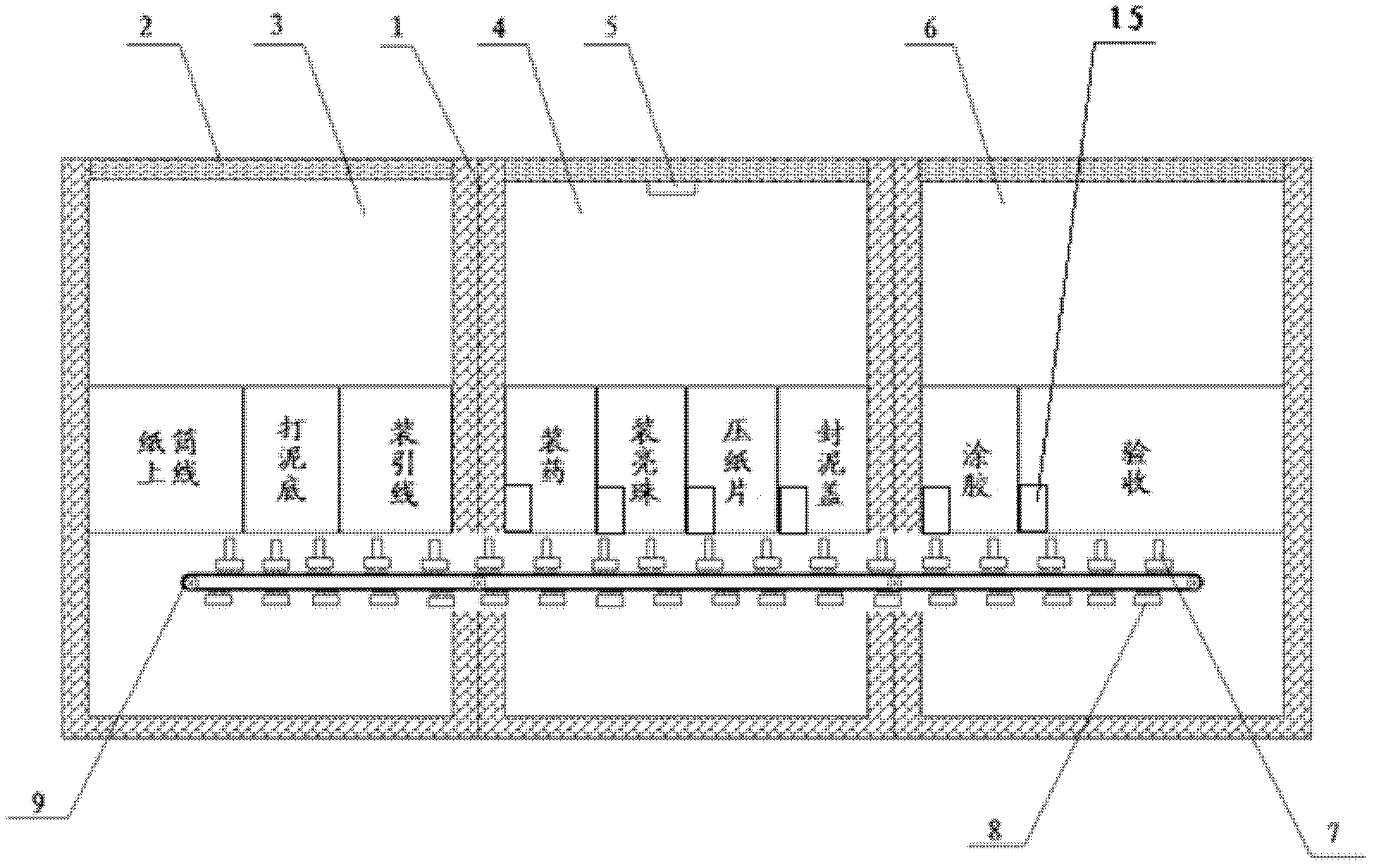

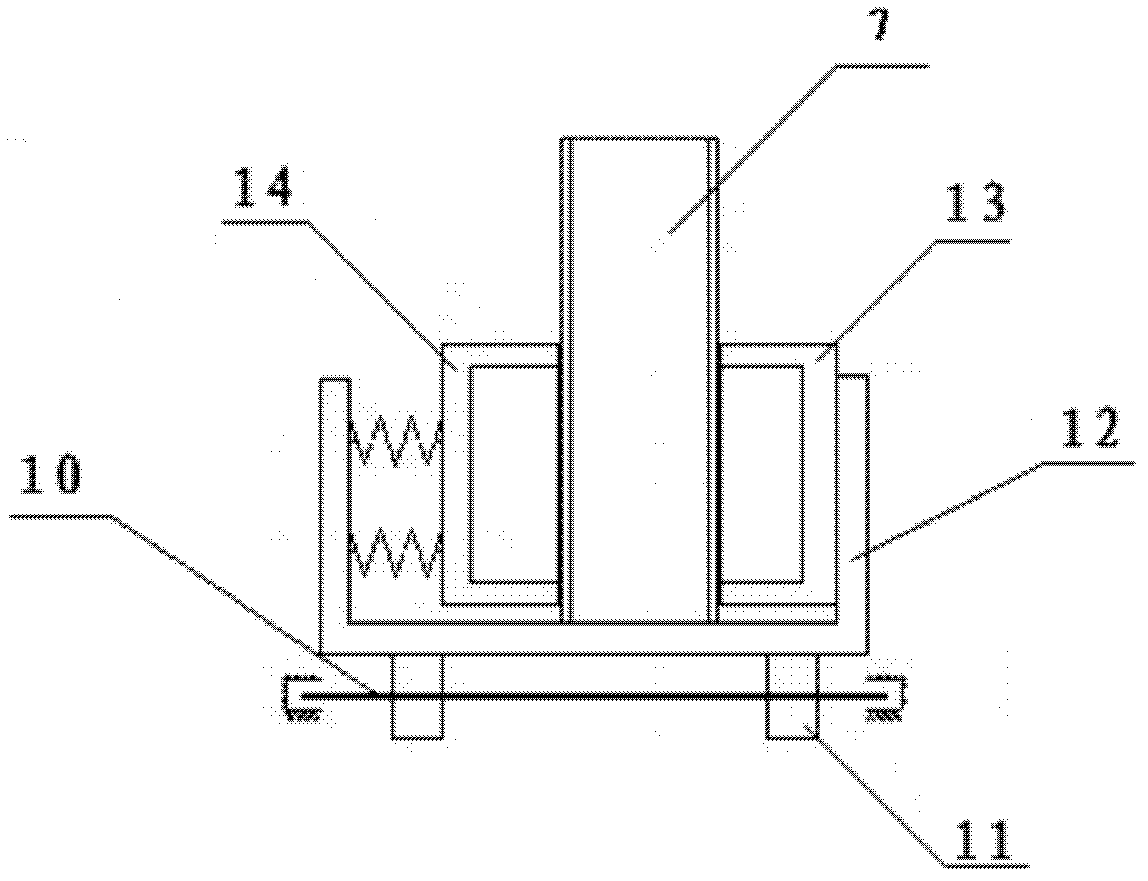

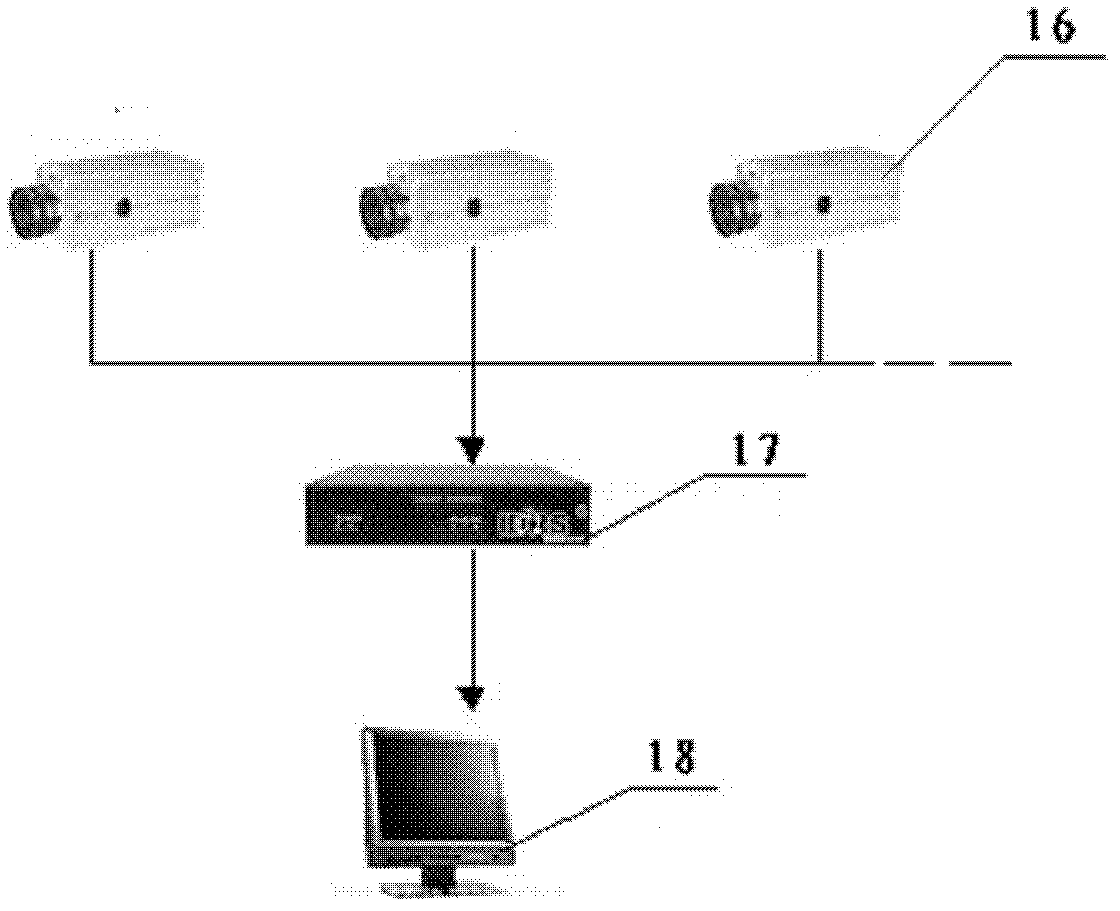

[0025] see figure 1 , reflecting a specific structure of the present invention, the pyrotechnic powder automatic charging system includes a chain-link conveyor belt 9 for transporting fireworks paper tubes 7 running through three working areas. A fire-proof and explosion-proof wall 1 is set between the three working areas, and an explosion-venting ceiling 2 is set on the top of the working area; the first working area 3 is located at the head end of the chain-link conveyor belt 9, including three on-line, mud-bottomed, and lead-in installation. unit of work. The second working area 4 includes four working units of charging, bright beads, paper pressing, and mud sealing cover. There are automatic fire extinguishing devices and fire detection probes 5 in this area; the third working area 6 includes two units of gluing and acceptance. Working unit: The charging system also includes a detection unit, which is composed of distance measuring sensors 15 arranged in front of each wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com