Automatic rowing device of combined fireworks

A combination of fireworks and automatic technology, applied in the direction of fireworks, offensive equipment, weapon types, etc., can solve problems such as difficulty, achieve high production efficiency, stable equipment operation, and no need for manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

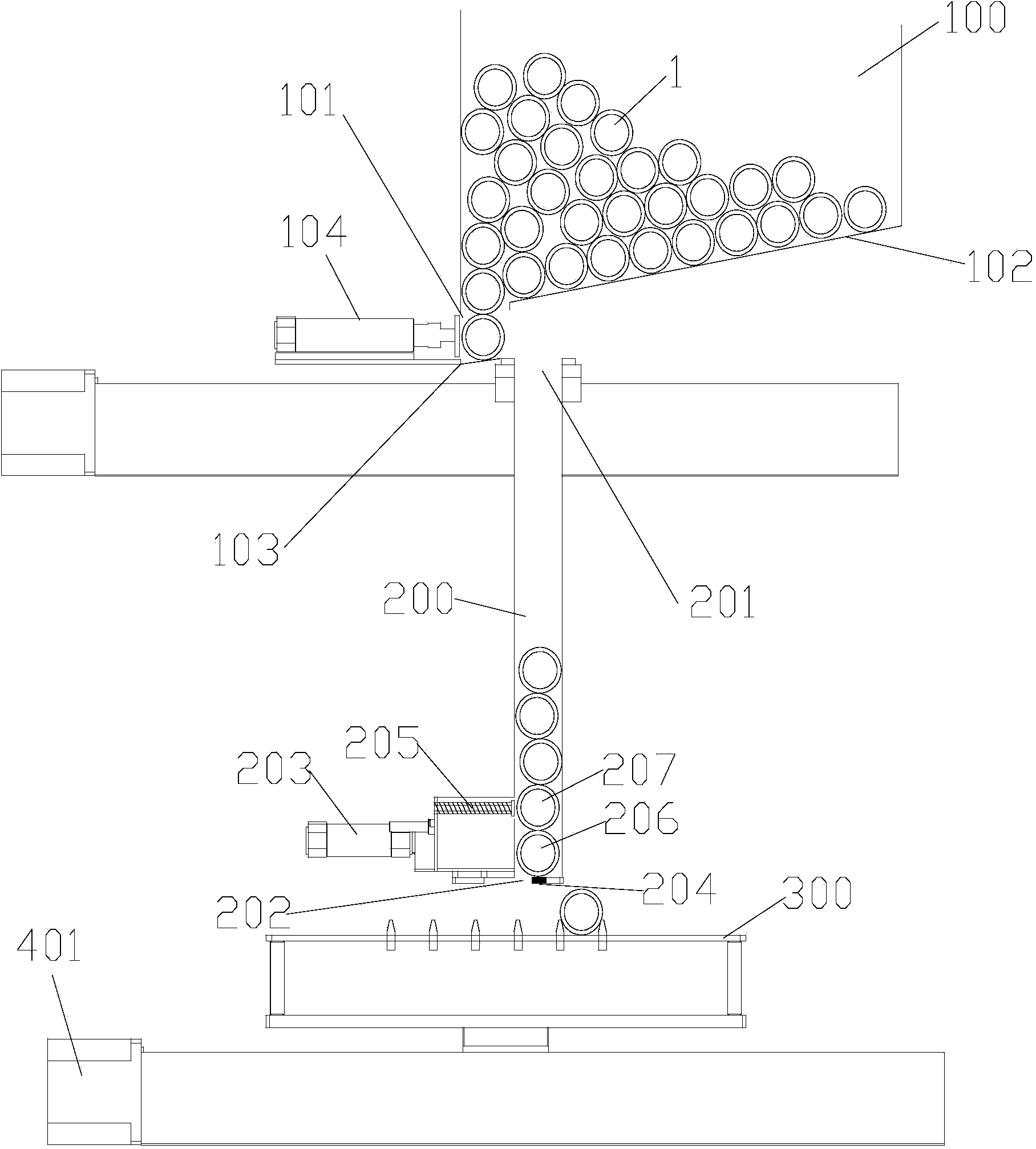

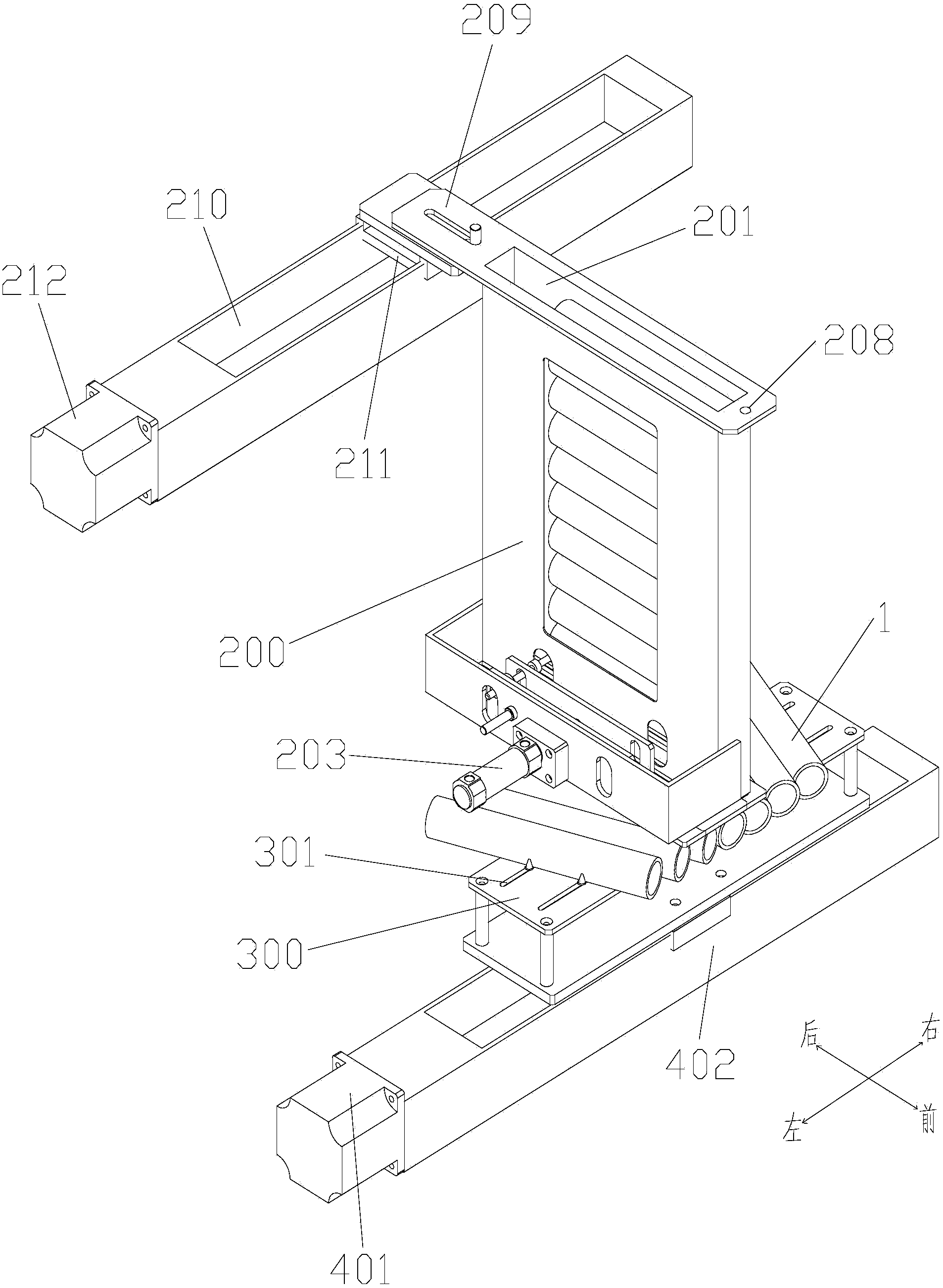

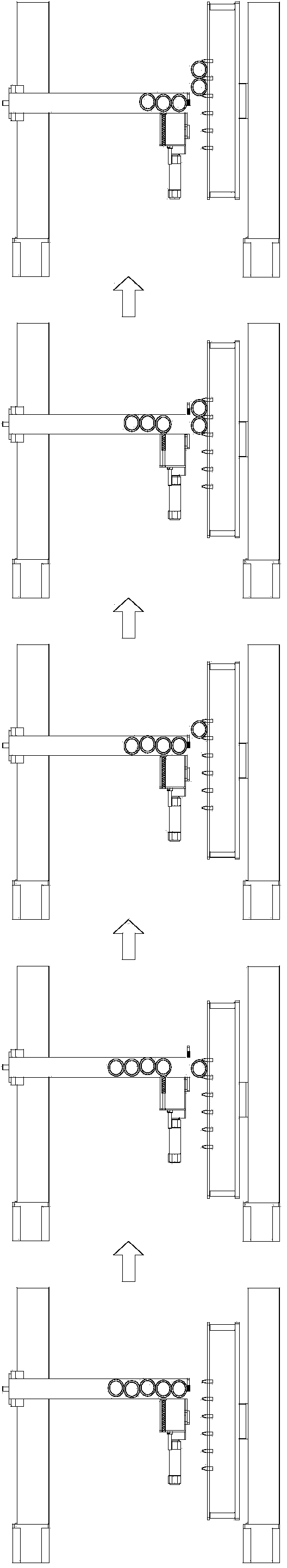

[0031] Embodiment 1: see attached Figure 1-9 , reflecting a specific structure of the present invention, this model can process vertical, fan-shaped, W-shaped, V-shaped, etc. tube rows with or without spacing between the paper tubes.

[0032]The automatic arranging device for combined fireworks includes a lower hopper 100 for storing a plurality of fireworks tubes 1, the bottom 102 of the lower hopper 100 is inclined toward the outlet 101, and makes each fireworks tube 1 fall sequentially along the outlet 101; the outlet 101 The lower side is provided with a firework tube support platform 103 and a lateral push cylinder 104 to form a first blanking control mechanism. Utilize the self-weight of the fireworks cylinder 1 to make it move toward the outlet 101 and drop onto the platform 103 one by one, and push the cylinder 104 laterally to push them into the channel 200 below one by one. The number of times the cylinder 104 is pushed laterally represents the number of falling fi...

Embodiment 2

[0039] Example 2: see Figure 10 The automatic arranging device for combined fireworks includes a lower hopper 501 that stores a plurality of fireworks tubes, and the outlet of the lower hopper is provided with a third blanking control mechanism that makes the fireworks tubes fall one by one; the bottom of the lower hopper 501 is arranged to accept the falling fireworks tubes The material receiving tray 503 is provided with a firework tube positioning mechanism (including a positioning groove and a positioning pin 504) on the material receiving tray 503 to accept the falling fireworks tube and keep it fixed according to the falling position; the material receiving tray 503 is provided with The displacement driving mechanism 505 drives the material receiving tray 503 to reciprocate and translate in a straight line; each working mechanism coordinates and works according to the working procedure under the action of the control system. The third blanking control mechanism of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com