Electrostatic-spinning nano fiber air filter material and preparation method thereof

An air filter material and nanofiber technology, applied in chemical instruments and methods, textiles and papermaking, non-woven fabrics, etc., can solve the problems of general filtration efficiency and poor mechanical properties of glass fiber membranes, and achieve controllability and good repeatability , solve the effect of high resistance and low filter resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

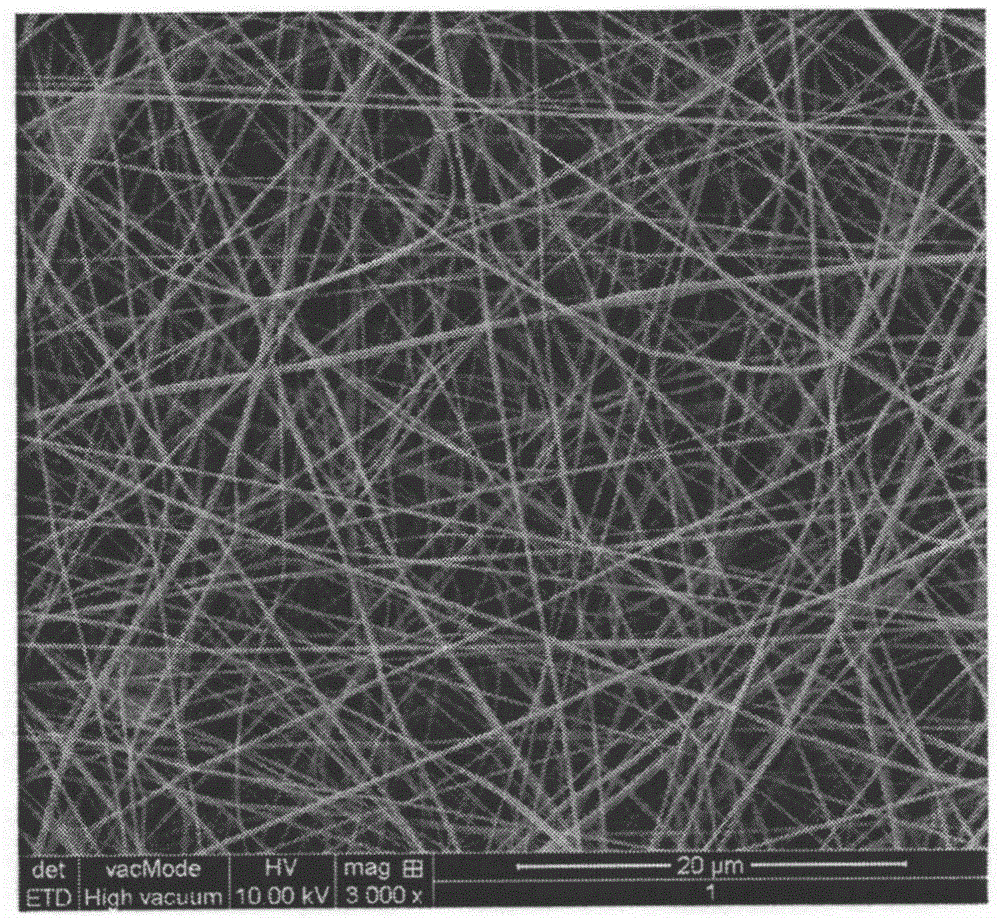

[0038] Dissolve 5g of polyacrylonitrile in 45g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g) spinning solution. Electrospinning was carried out with the patented ZL201320046228.5 spinning nozzle, the parameters were: voltage 60KV, receiving distance 15cm, drum speed 30r / min, spinning time 10min, ambient temperature 25°C, ambient relative humidity 55%.

[0039]The drum is used as the receiving device to prepare a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability. The filter material prepared by the above method is made into 3 air filtration product samples. Their fiber diameter, pore size, and filtration efficiency , filter resistance, air permeability and moisture permeability test data are shown in Table 1.

[0040] Table 1

[0041]

Embodiment 2

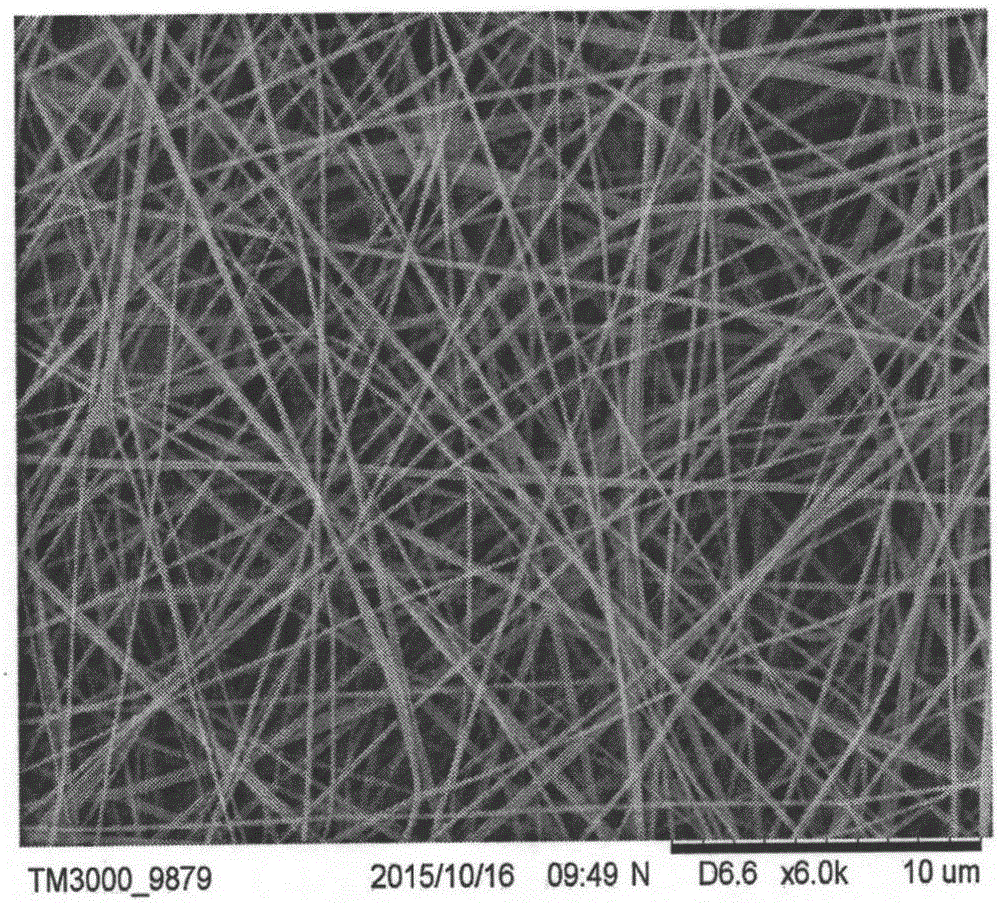

[0043] Dissolve 7g of polyacrylonitrile in 43g of N,N-dimethylformamide, stir for 8h until completely dissolved to obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g) spinning solution. Electrospinning was carried out using the patented ZL201320046228.5 spinning nozzle, the parameters were: voltage 68KV, receiving distance 20cm, drum speed 30r / min, spinning time 15min, ambient temperature 27°C, ambient relative humidity 45%.

[0044] The drum is used as the receiving device to prepare a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability. The filter material prepared by the above method is made into 3 air filtration product samples. Their fiber diameter, pore size, and filtration efficiency , filter resistance, air permeability and moisture permeability test data are shown in Table 2.

[0045] Table 2

[0046]

Embodiment 3

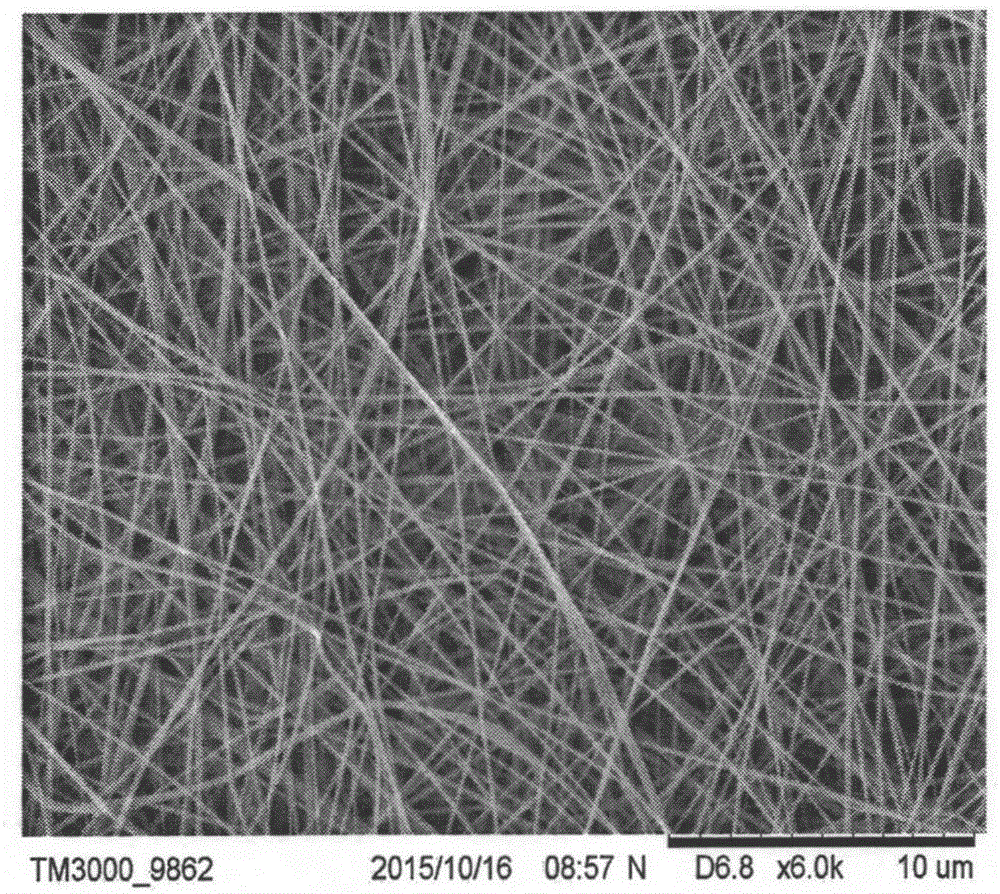

[0048] Dissolve 5g of polyvinylidene fluoride in 45g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g). Amide spinning solution. Electrospinning was carried out using the patented ZL201320046228.5 spinning nozzle. The parameters were: voltage 65KV, receiving distance 15cm, drum speed 60r / min, spinning time 20min, ambient temperature 25°C, and ambient relative humidity 40%.

[0049] The drum is used as the receiving device to prepare a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability. The filter material prepared by the above method is made into 3 air filtration product samples. Their fiber diameter, pore size, and filtration efficiency , filter resistance, air permeability and moisture permeability test data are shown in Table 3.

[0050] table 3

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com