Preparation method and device for electrospinning nanofiber yarn

A nanofiber and preparation device technology, which is applied in fiber processing, textiles, papermaking, yarn, etc., can solve the problems of limited application range and small output, and achieve the effect of convenient operation and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

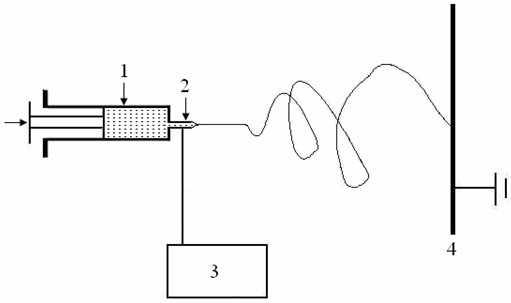

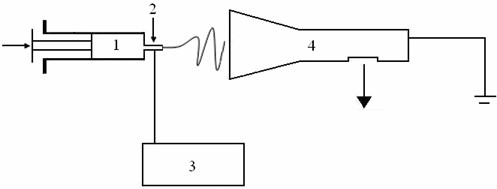

Method used

Image

Examples

Embodiment 1

[0036] The electrospinning parameters were set as follows:

[0037] (1) The electrospinning solution is a polyacrylonitrile solution, and the mass fraction of the solution is 12%;

[0038] (2) The spinning distance from the spinneret to the receiving device is 3cm;

[0039] (3) The spinning voltage is 12kV;

[0040] (4) The flow rate of electrospinning solution is 0.005ml / min;

[0041] (5) The mass content of lithium chloride is 0.6%;

[0042] (6) The pumping rate of the vacuum pump is 360L / min;

[0043] The various stages of nanofiber forming yarn such as Figure 4 shown. Among them, b, c, and d are the photos taken by the stereo microscope respectively, and the magnification is 300 times.

[0044] In the process of obtaining the nanofiber yarn by using the device, the morphology of the fiber is divided into three stages, which are the fiber orientation arrangement, the transition zone in the middle, and the nanofiber yarn at the rear end.

[0045] The morphology of nano...

Embodiment 2

[0047] The electrospinning parameters were set as follows:

[0048] (1) The flow rate of electrospinning solution is 0.0075ml / min;

[0049] Other electrospinning parameters are the same as above.

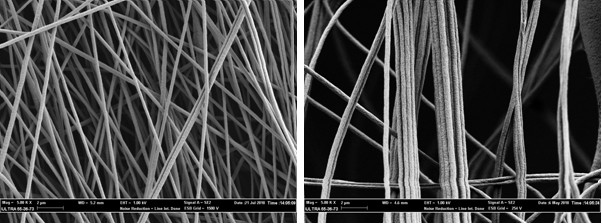

[0050] The obtained nanofiber yarn Figure 4 , the fiber shape in the yarn is as Figure 6 shown. There are still fiber entanglements in the yarn, but the number of entangled fibers is reduced, and the straightness of the fiber alignment along the yarn axis is improved.

Embodiment 3

[0052] The electrospinning parameters were set as follows:

[0053] (1) The flow rate of electrospinning solution is 0.01ml / min;

[0054] Other electrospinning parameters are the same as above.

[0055] The obtained nanofiber yarn Figure 4 , the fiber shape in the yarn is as Figure 7 shown. The flow rate of the solution in the spinneret increases, the fibers are crowded and bent, and the straightness of the fibers along the yarn axis is weakened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com