Nanofiltration membrane, preparation method and dye separation method

A nanofiltration membrane and separation layer technology, applied in the field of membrane separation, can solve the problems of high molecular weight cut-off, low membrane strength, and low flux of nanofiltration membranes, and achieve good separation performance, good stability, and performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

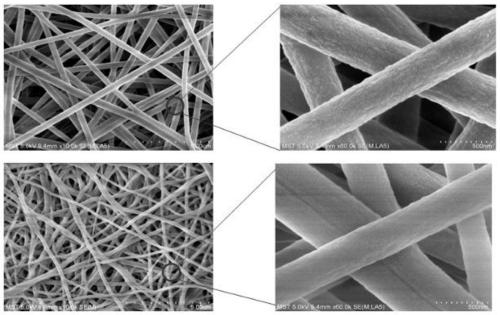

[0056] The detailed preparation method of the double-layer structure nanofibrous membrane is as follows.

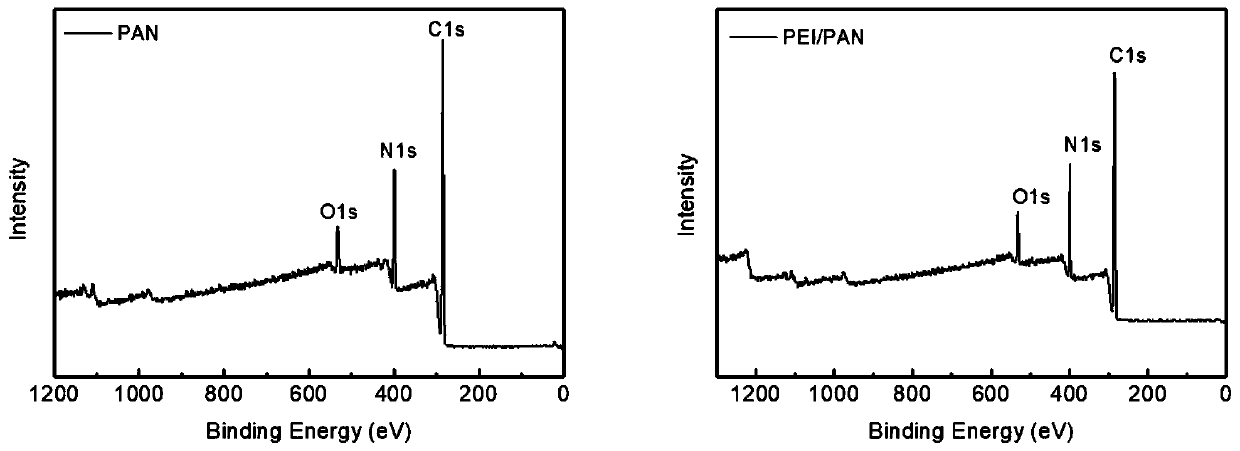

[0057] First, polyacrylonitrile (PAN) was dissolved in N,N-dimethylformamide (DMF) at 60° C. for 12 hours, and left to stand for 12 hours to defoam. A homogeneous solution with a mass fraction of 10 wt % was obtained as a PAN spinning solution.

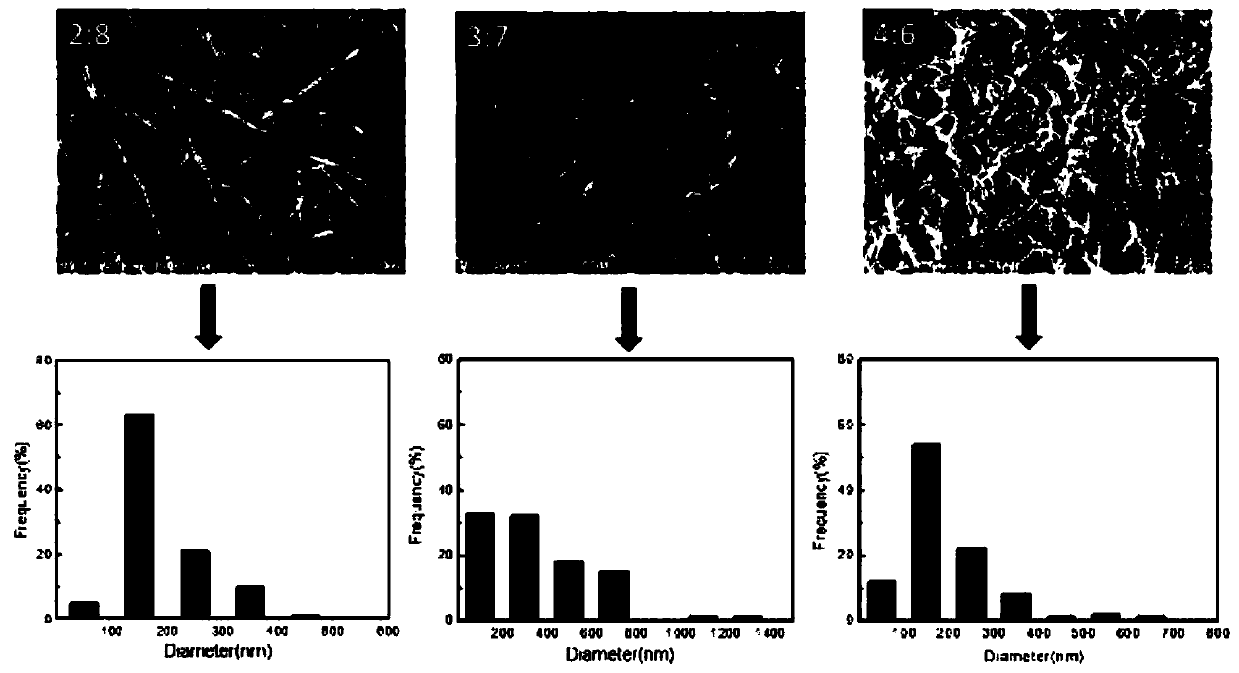

[0058] Secondly, mix polyethyleneimine (PEI) and polyacrylonitrile (PAN) in DMF at a certain ratio (fixed total weight is 10wt%) at 60°C for 12 hours until it becomes a homogeneous solution, and stand for 12 hours for defoaming , Prepare transition layer as PEI / PAN spinning solution.

[0059] 10 mL of the prepared PAN spinning solution was electrospun onto aluminum foil. Optimized voltage (20 kV), flow rate (1.0 ml / min) and distance between the needle tip and the collector (14 cm) to obtain a polyacrylonitrile electrospun base film (named PAN base film in the following examples) .

[0060] Then, 5 ml of the prepared PAN / PEI s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com