Multiple response type filtration-controllable electrospun nanofiber membrane and preparation method thereof

A nanofiber membrane, responsive technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of no intelligent separation characteristics, complex operation process, non-reusability, etc., to achieve simple and easy experimental operation, filtration reaction Rapid, low production cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of electrospinning polymer solution: Weigh 0.5 g of electrospinning polymer monomer N-isopropylacrylamide and acrylic acid with a precision balance, add ethanol under nitrogen and ice water bath -1 °C protection Green solvent with a water volume ratio of 5:7, magnetically stirred for 10 minutes until uniformly mixed, added 0.1 g APS and 10 μL TEMED in sequence, controlled the reaction temperature at 40 ° C, and the reaction time was 10 h to synthesize a spinning solution with a polymer concentration of 10 wt%. ;

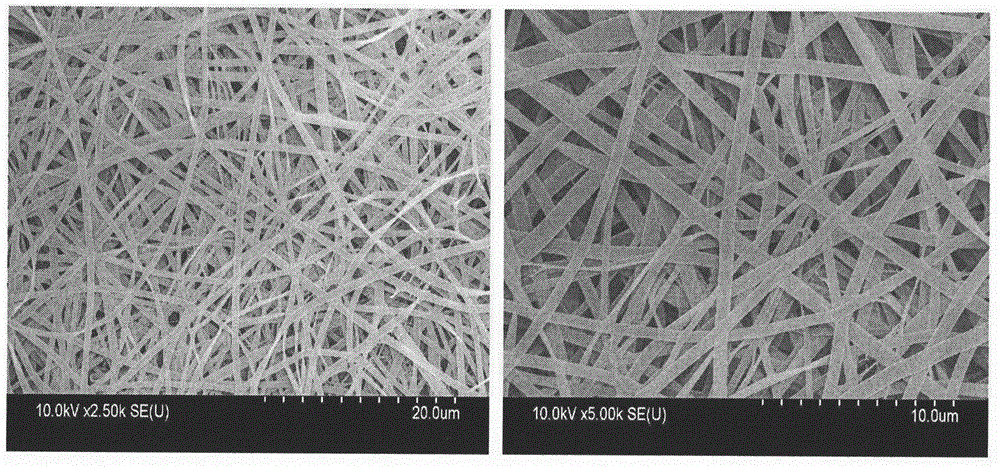

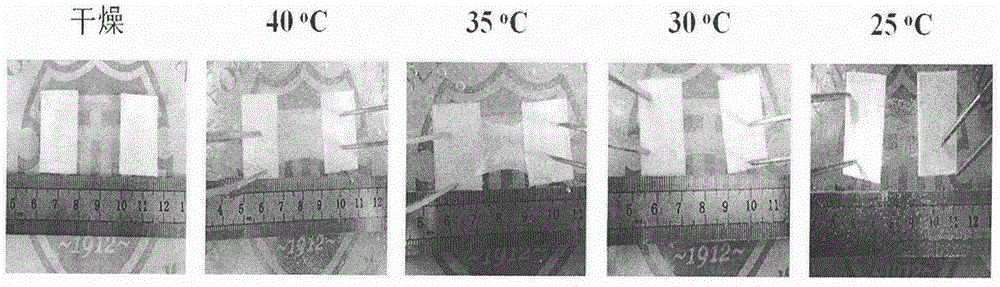

[0033] 2) Spinning of nanofiber membrane: First, put the mixed solution obtained in step 1 under magnetic stirring for 15 minutes to make the mixed solution uniform and obtain a uniform electrospinning spinning solution, then put it into a 15mL plastic syringe, and use the purchased electrostatic Spinning device, adjust spinning parameters such as spinning voltage 15kV, receiving distance 15cm, liquid feeding rate 0.5mL / h, etc., to avoid a large...

Embodiment 2

[0036] 1) Preparation of electrospinning polymer solution: Weigh 1.2 g of electrospinning polymer monomer N-vinyl caprolactam and methacrylic acid with a precision balance, and add A green solvent with a volume ratio of ethanol / water of 4:1, stirred magnetically for 20 minutes until uniformly mixed, added 0.15 g APS and 15 μL TEMED in sequence, controlled the reaction temperature at 30 ° C, and the reaction time was 11 h, and the spinning polymer concentration was 12 wt%. liquid;

[0037] 2) Spinning of nanofiber membrane: First, place the mixed solution obtained in step 1 under magnetic stirring for 15 minutes to make the mixed solution uniform and obtain a uniform electrospinning spinning solution, then put it into a 10mL metal syringe, and use a self-made electrostatic spinning solution. Spinning device, adjust spinning parameters such as spinning voltage 10kV, receiving distance 10cm, liquid feeding rate 0.3mL / h, etc., to avoid a large amount of spinning liquid overflowing...

Embodiment 3

[0040] 1) Preparation of electrospinning polymer solution: 1.5 g of electrospinning monomer N, N'-diethylacrylamide and N, N-dimethylaminoethyl ester were weighed by a precision balance, Under the protection of nitrogen and ice-water bath at 0°C, add a green solvent with a volume ratio of ethanol / water of 4:7, stir magnetically for 25 minutes until uniformly mixed, then add 0.15g APS and 20μL TEMED in sequence, control the reaction temperature to 40°C, and the reaction time to 12h. Synthetic polymer concentration is the spinning solution of 15wt%;

[0041] 2) Spinning of nanofiber membrane: First, place the mixed solution obtained in step 1 under magnetic stirring for 30 minutes to make the mixed solution uniform and obtain a uniform electrospinning spinning solution, then put it into a 15mL plastic syringe, and use the purchased electrostatic Spinning device, adjust the spinning parameters such as spinning voltage 15kV, receiving distance 10cm, liquid feeding rate 0.7mL / h, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com