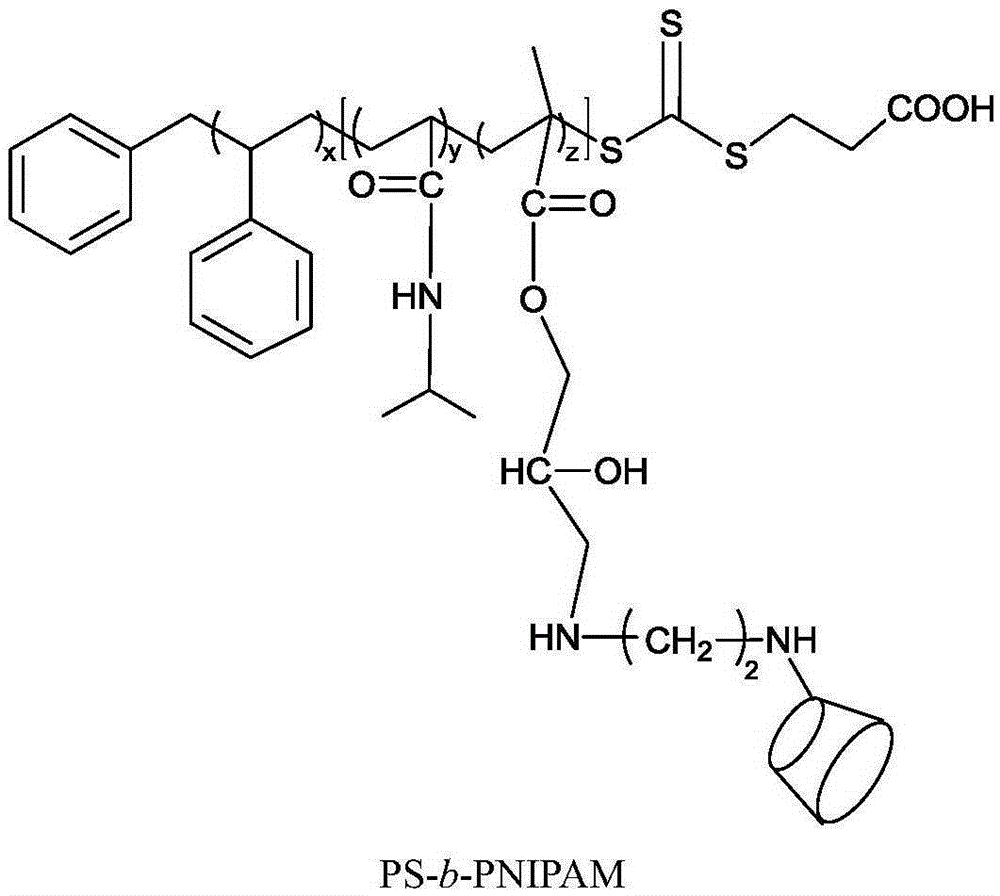

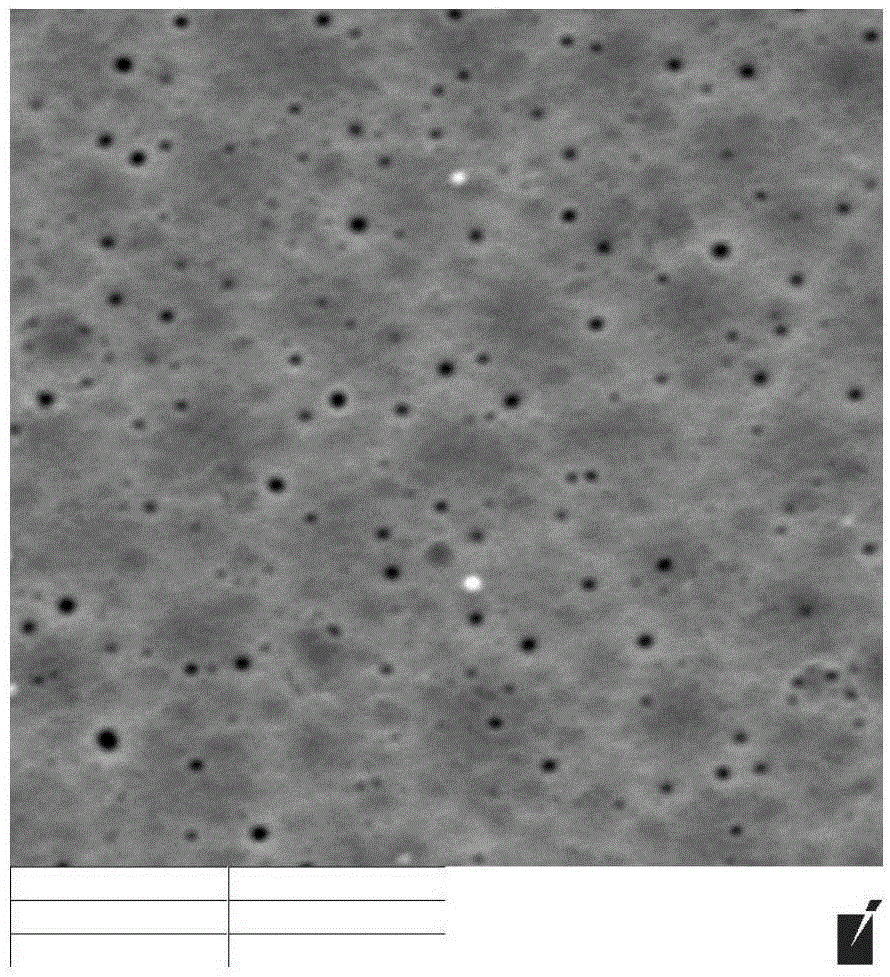

Preparation method of block copolymer nanoporous membrane containing cyclodextrin chain segments and having temperature responsiveness

A block copolymer and temperature-responsive technology, which is applied in the field of preparation of block copolymer nanoporous membranes, can solve the problems of complex processing procedures, low degree of membrane functionalization, poor controllability of molecular structure, etc., so as to improve the selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Potassium phosphate (2 g, 9.43 mmol) and 16 mL of acetone were added to a dry one-necked flask, and magnetically stirred for 8 h to fully dissolve it. Mercaptopropionic acid (1g, 9.43mmol) was added dropwise to the above-mentioned flask, continued magnetic stirring for 2h, and carbon disulfide (2.15g, 28.3mmol) was added dropwise in the above-mentioned flask, and benzyl bromide (1.61g, 9.43mmol) was added and the stirring reaction was continued for 2h. After the reaction was completed, saturated saline and diethyl ether were sequentially added into the single-necked flask for extraction and washing, and the resulting diethyl ether layer was collected and distilled under reduced pressure to obtain a yellow liquid. Add an equal amount of saturated saline and diethyl ether to the yellow liquid for secondary extraction and washing, collect the final organic layer, add anhydrous sodium sulfate twice the volume of the product to it, stir magnetically for 2 hours, and filter i...

Embodiment 2

[0058]Potassium phosphate (4 g, 18.86 mmol) and 30 mL of acetone were added to a dry one-necked flask, and magnetically stirred for 10 h. Mercaptopropionic acid (2g, 18.86mmol) was added dropwise in the above-mentioned flask, continued magnetic stirring for 2h, carbon disulfide (4.3g, 56.6mmol) was added dropwise in the above-mentioned flask and continued to stir for 2h, and then benzyl bromide (3.22g , 18.86mmol) was added and stirring was continued for 2h. After the reaction was completed, saturated saline and diethyl ether were sequentially added into the single-necked flask for extraction and washing, and the resulting diethyl ether layer was collected and distilled under reduced pressure to obtain a yellow liquid. Extract and wash again with saturated saline and ether, collect the final organic layer, add anhydrous sodium sulfate twice the volume of the product to it, stir magnetically for 2 hours, filter with a G4 sand core funnel to remove anhydrous sodium sulfate, and ...

Embodiment 3

[0065] Potassium phosphate (6 g, 28.29 mmol) and 46 mL of acetone were added to a dry one-necked flask and magnetically stirred for 12 h. Mercaptopropionic acid (3g, 28.29mmol) was added dropwise in the above-mentioned flask, and carbon disulfide (6.45g, 84.9mmol) was added dropwise in the above-mentioned flask after continuing to stir for 2h, and then benzyl bromide (4.83g , 28.29mmol) was added and the stirring reaction was continued for 2h. After the reaction was completed, saturated saline and diethyl ether were sequentially added into the single-necked flask for extraction and washing, and the resulting diethyl ether layer was collected and distilled under reduced pressure to obtain a yellow liquid. Extract and wash again with saturated brine and ether, collect the final organic layer, add anhydrous sodium sulfate twice the volume of the product to it, stir magnetically for 2 hours, filter with a G4 sand core funnel to remove anhydrous sodium sulfate, and distill under re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com