Basic shaft type metal 3D printing equipment

A 3D printing and metal technology, applied in the field of basic shaft metal 3D printing equipment, can solve the problems of poor screening effect of the powder sieve, inconvenient metal powder crushing, and reduced screening efficiency, etc., to achieve good printing effect and structure. Simple, powder firming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

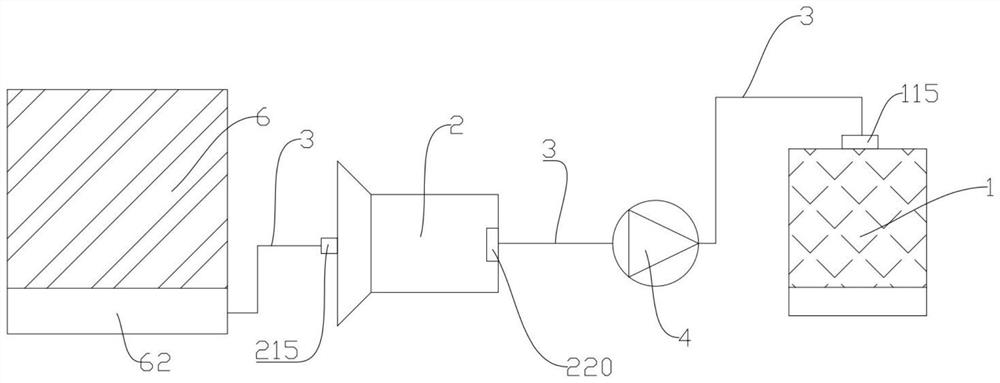

[0063] Such as Figures 1 to 18 As shown, a base shaft type metal 3D printing equipment includes an integrated powder replenishing and scraping device, including a powder suction device and a powder sieving machine;

[0064] The drawer of the powder replenishing and powder scraping integrated device is connected to the powder suction port of the powder suction device through a powder feeding pipe;

[0065] The discharge pipe of the powder suction device communicates with the feeding cylinder of the powder sieving machine through the powder feeding pipe; the powder feeding pipe is provided with a vacuum conveyor;

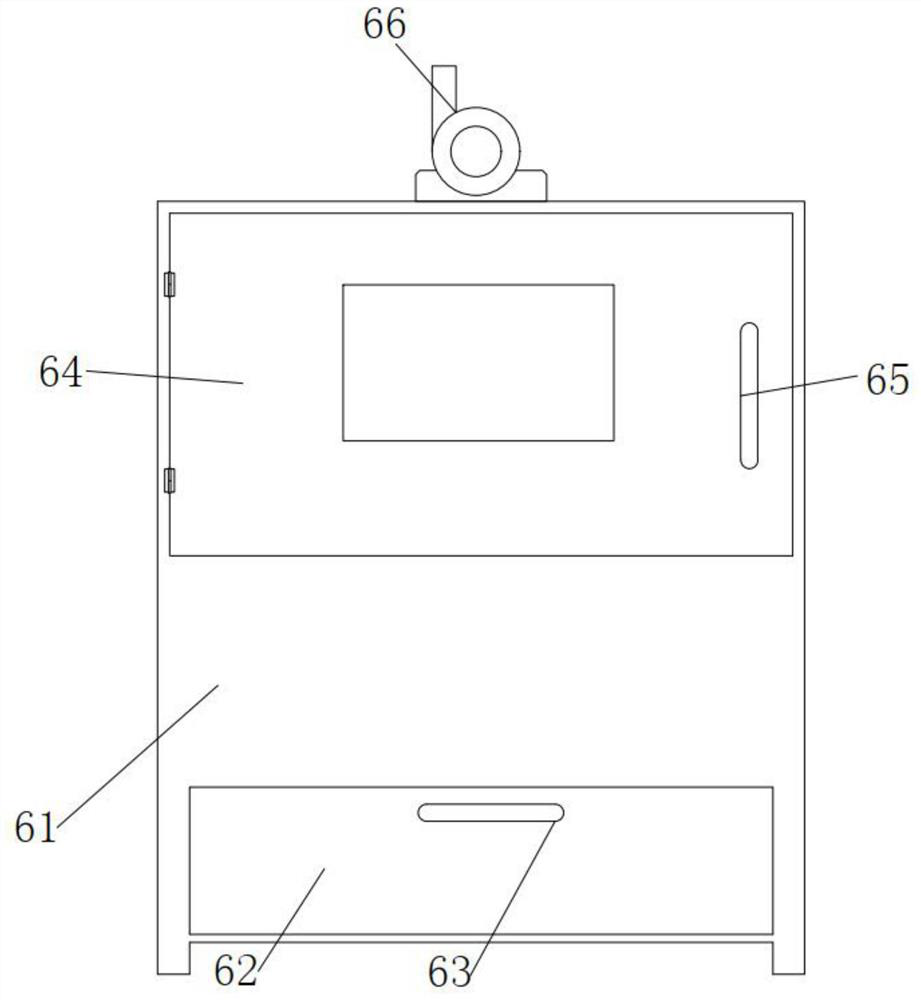

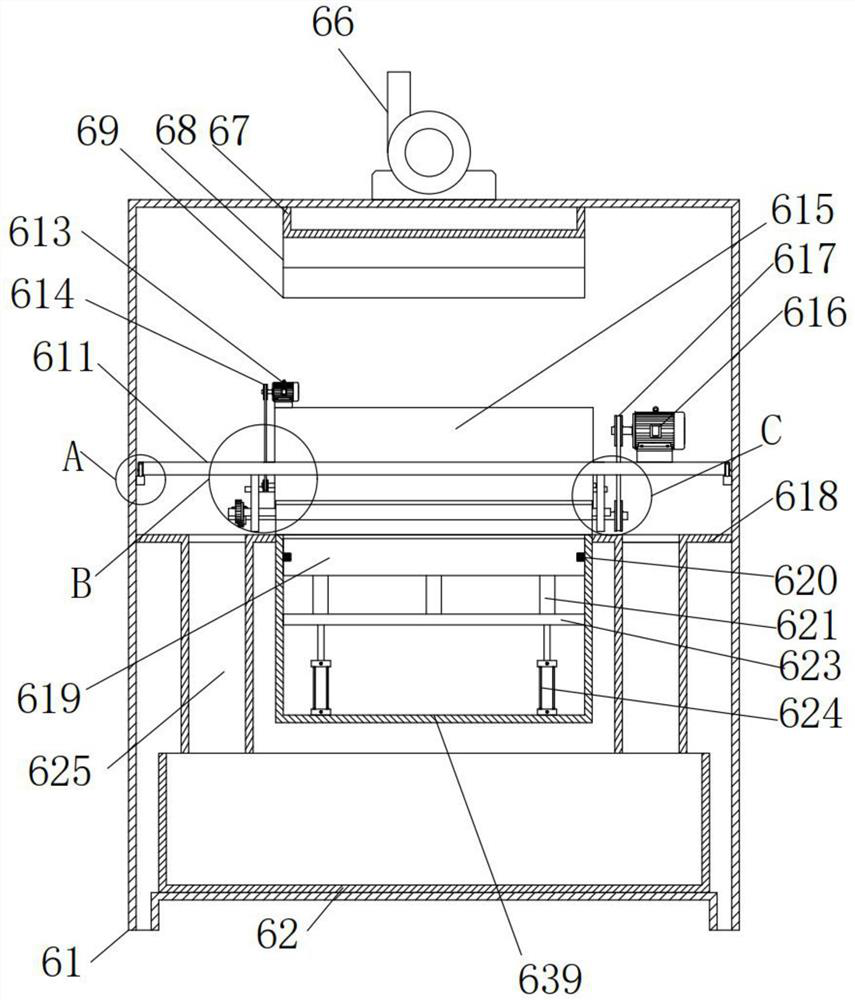

[0066] The powder replenishing and powder scraping integrated device includes a fuselage, the outer wall of the fuselage is rotatably connected with a box door, the outer wall of the box door is fixedly connected with a second handle, the inside of the fuselage is fixedly connected with a partition, and the partition The inner wall is provided with a recovery channe...

Embodiment 2

[0070] like Figures 1 to 18 As shown, a base shaft type metal 3D printing equipment includes an integrated powder replenishing and scraping device, including a powder suction device and a powder sieving machine;

[0071] The drawer of the powder replenishing and powder scraping integrated device is connected to the powder suction port of the powder suction device through a powder feeding pipe;

[0072] The discharge pipe of the powder suction device communicates with the feeding cylinder of the powder sieving machine through the powder feeding pipe; the powder feeding pipe is provided with a vacuum conveyor;

[0073] refer to Figure 2-10 The integrated powder replenishing and scraping device of the present invention includes a fuselage, the outer wall of the fuselage is rotatably connected with a box door, the outer wall of the box door is fixedly connected with a second handle, the inner side of the fuselage is fixedly connected with a partition, and the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com