Electrospun nanofiber composite carbon aerogel and preparation method thereof

A technology of nanofibers and carbon aerogels, which is applied in the fields of fiber chemical characteristics, ceramic products, textiles and papermaking, etc., can solve the problems of uneven dispersion of supports, high packing density of raw materials, complicated preparation methods, etc. The effect of controllable shape, reduced bulk density and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

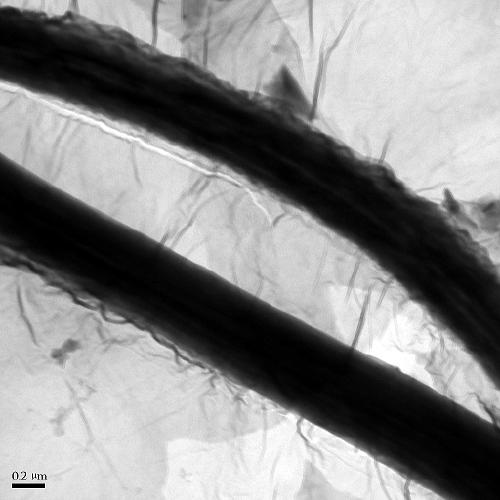

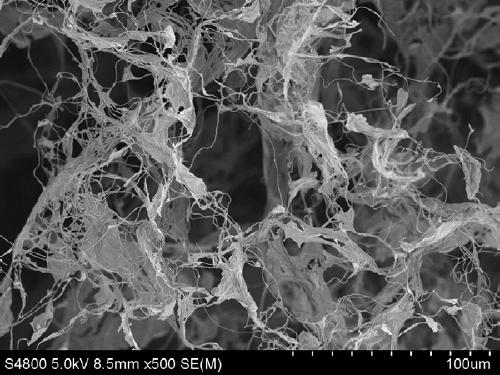

[0033] Preparation of nanofiber composite carbon airgel materials from polyacrylonitrile (PAN) and graphene oxide (GO):

[0034] (1) Preparation of spinning solution: Weigh 2 g of PAN polymer powder, add it to dimethylformamide (DMF), put it in a water bath at 60 °C and stir until dissolved, and obtain a PAN spinning solution with a mass fraction of 10%. liquid;

[0035] (2) Preparation of nanofiber / support dispersion: transfer the spinning solution in step (1) into a syringe and connect it to an autosampler, connect the needle to a high-voltage power supply for electrospinning, and the receiving solution is 0.2 mg / mL GO dispersion in water. Spinning conditions: the spinning voltage is 20 kV, -10 kV, the flow rate of the spinning solution is 1 mL / h, the distance between the needle and the receiving liquid surface is 15 cm, and the fiber density is 2 mg / mL;

[0036] (3) Preparation of nanofiber / support composite block: transfer the PAN nanofiber / GO composite dispersion prepar...

Embodiment 2

[0039] With PAN and manganese dioxide nanosheets (MnO 2 ) as raw material to prepare nanofiber composite carbon airgel material:

[0040] (1) Preparation of spinning solution: Weigh 2 g of PAN polymer powder, add it to DMF, place it in a water bath at 60 °C and stir until dissolved to obtain a PAN spinning solution with a mass fraction of 10%;

[0041] (2) Preparation of nanofiber / support dispersion: transfer the spinning solution in step (1) into a syringe and connect it to an autosampler, connect the needle to a high-voltage power supply for electrospinning, and the receiving solution is 0.5 mg / mL MnO2 / 50% tert-butanol / water dispersion. Spinning conditions: the spinning voltage is 15 kV, -5 kV, the flow rate of the spinning solution is 2 mL / h, the distance between the needle and the receiving liquid surface is 20 cm, and the fiber density is 2 mg / mL;

[0042] (3) Preparation of nanofiber / support composite block: transfer the PAN nanofiber / MnO2 dispersion prepared in step (...

Embodiment 3

[0045] Preparation of nanofiber composite carbon airgel materials with PAN, polymethyl methacrylate (PMMA) and GO as raw materials:

[0046] (1) Preparation of spinning solution: Weigh 2 g of PAN and 1 g of PMMA polymer powder, add them to DMF, place in a 60 °C water bath and stir until dissolved to obtain a mixed spinning solution with a mass fraction of 15%;

[0047] (2) Preparation of nanofiber / support dispersion: transfer the spinning solution in step (1) into a syringe and connect it to an autosampler, connect the needle to a high-voltage power supply for electrospinning, and the receiving solution is 0.2 mg / mL GO / 50% ethanol / water dispersion. Spinning conditions: the spinning voltage is 30 kV, -5 kV, the flow rate of the spinning solution is 0.5 mL / h, the distance between the needle and the receiving liquid surface is 20 cm, and the fiber density is 1 mg / mL;

[0048] (3) Preparation of nanofiber / support composite block: transfer the PAN / PMMA nanofiber / GO dispersion prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com