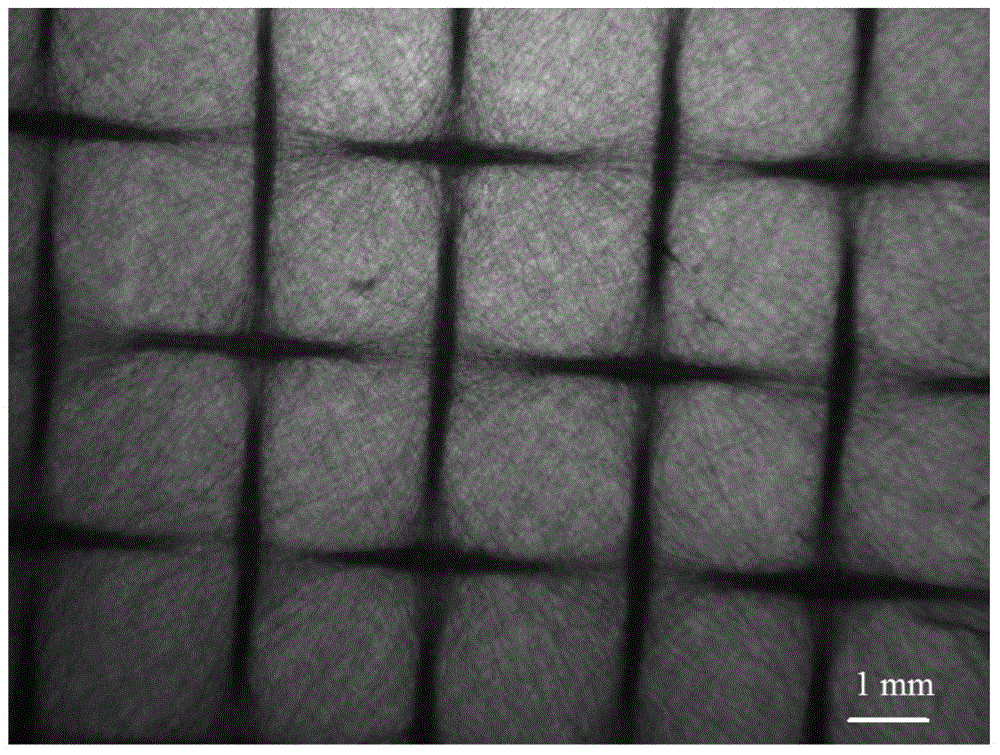

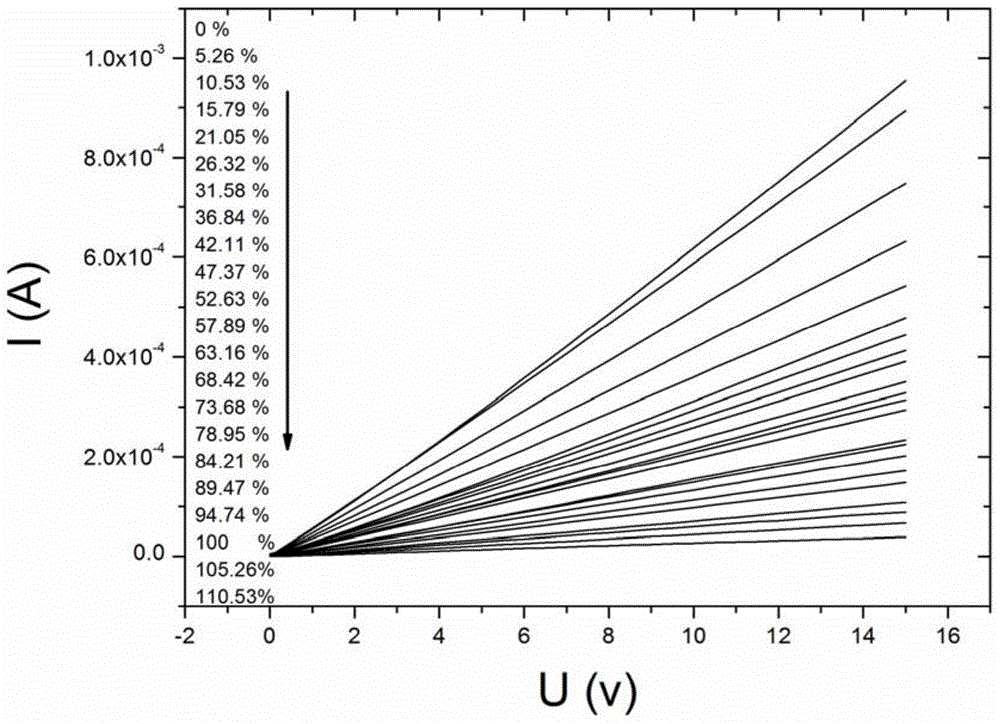

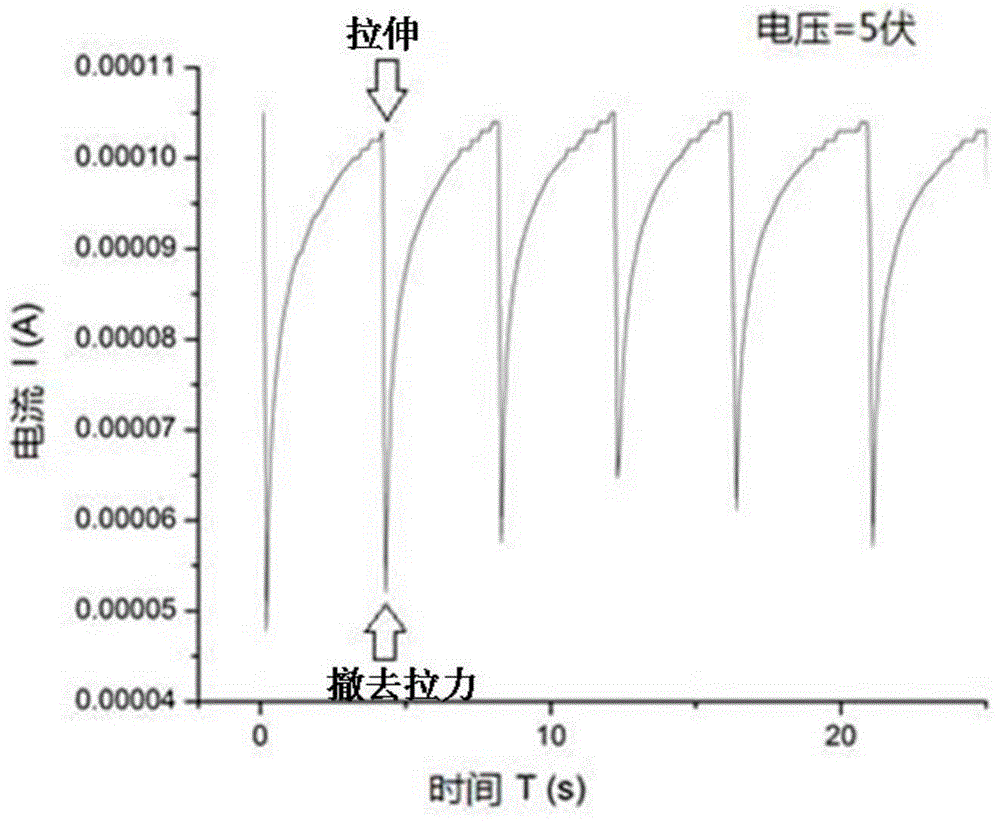

Force-sensitive stretchable electro-spinning patterning conductive nanofiber membrane and preparation method thereof

A nanofiber film, conductive nanotechnology, applied in fiber treatment, textiles and papermaking, non-woven fabrics, etc., to achieve good recovery characteristics, wide application, simple methods and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a force-sensitive stretchable electrospun patterned conductive nanofiber film, comprising the following steps:

[0027] (1) Preparation of spinning precursor solution: 1.0 grams of polyvinylpyrrolidone powder with a molecular weight of 1.3 million and 3.0 grams of poly(3,4-ethylenedioxythiophene) / polystyrenesulfonic acid aqueous solution with a mass fraction of 2.8wt% , and 2 grams of absolute ethanol were mixed, then 0.2 grams of dimethyl sulfoxide was added, and magnetically stirred at room temperature for 5 hours to make the solution evenly mixed, and then left to stand for 90 minutes to obtain a uniform electrospinning precursor solution;

[0028] (2) The spinning precursor solution prepared in step (1) is placed in a spinning solution container with a metal nozzle. Directly below the injection port of the metal nozzle and connected to the negative pole of the DC high-voltage power supply, adjust the spinning distance, the precursor solution f...

Embodiment 2

[0031] The preparation method of the force-sensitive stretchable electrospun patterned conductive nanofiber membrane of Example 2 is similar to that of Example 1, the difference is that step (1) prepares the spinning precursor solution: 1.0 g of undoped intrinsic state Polyaniline (molecular weight: 120,000) was mixed with 1.29 g of camphorsulfonic acid, dissolved in 100 ml of chloroform, and magnetically stirred at room temperature for 4 hours. The resulting dark green solution (doped polyaniline) was filtered, then 32 mg of polyethylene oxide (molecular weight 2,000,000) was added to the filtrate, and the solution was filtered again after magnetic stirring at room temperature for 2 hours to obtain a uniform electrospun Precursor solution; the spinning distance in step (2) is 10 centimeters, the spinning voltage is 14 kilovolts, and the spinning time is 15 minutes. The collection template is an insulating plastic net, and the insulating plastic net is lined with aluminum foil ...

Embodiment 3

[0034] The preparation method of the force-sensitive stretchable electrospun patterned conductive nanofiber membrane of embodiment 3 is similar to that of embodiment 1, the difference is: step (1) preparation of spinning precursor solution: 0.5 gram of polypyrrole powder (molecular weight greater than 1000 ) was mixed with 1.0 g of dodecylbenzenesulfonic acid, and dissolved in 10 ml of chloroform with ultrasonic stirring. The obtained solution (doped polypyrrole) is filtered with a Teflon filter membrane, the filtrate is evaporated and concentrated until the mass percentage of polypyrrole is about 35 wt%, and then polyvinyl cinnamate, polypyrrole and polycinnamic acid are added The mass ratio of vinyl ester was 4:1, and magnetic stirring at room temperature was carried out for 2 hours to obtain a uniform electrospinning precursor solution; the spinning distance in step (2) was 10 cm, the spinning voltage was 14 kV, and the spinning time 20 minutes, and the collection template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com