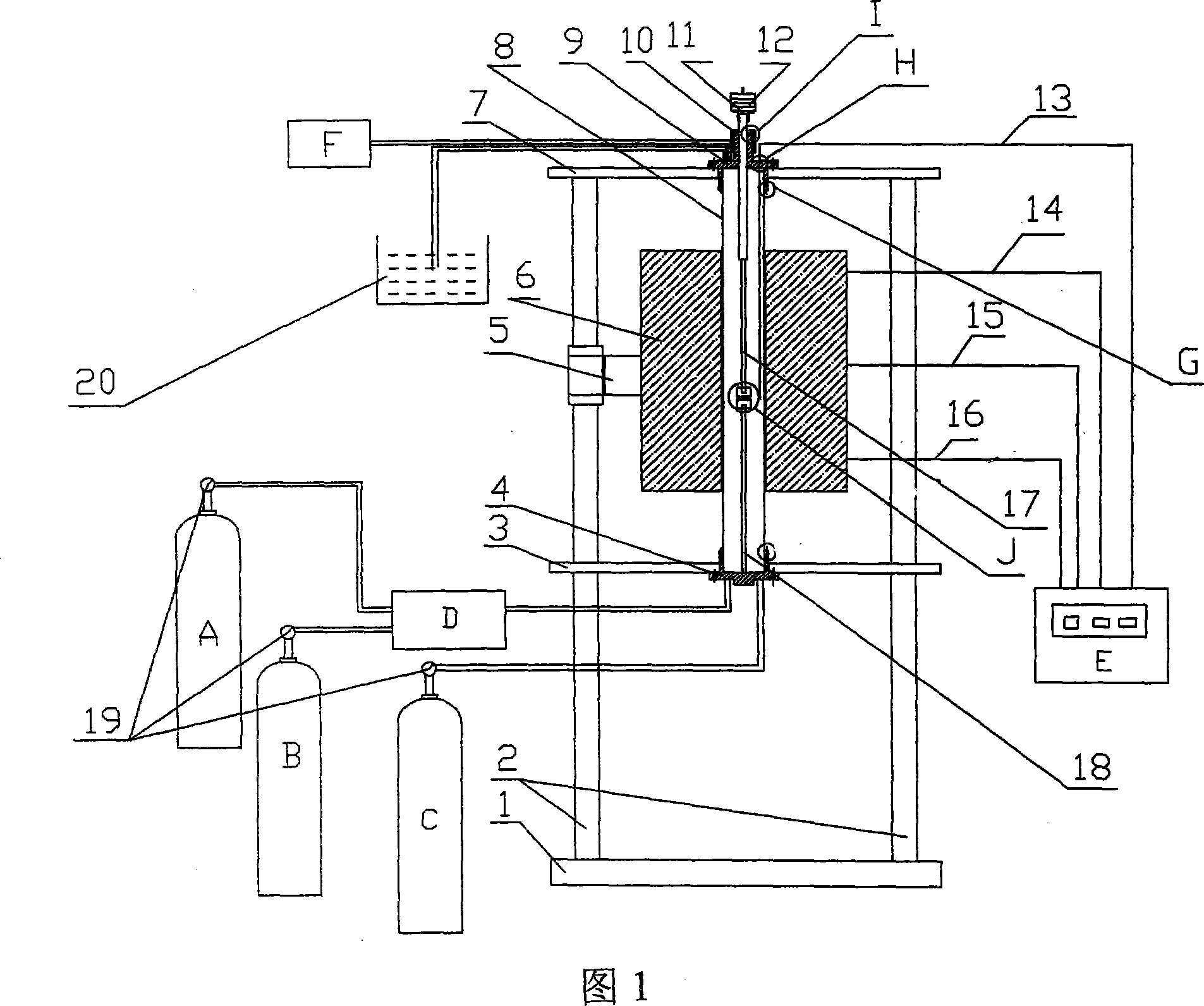

Multi-stress high-temperature corrosion testing system apparatus

A high-temperature corrosion and test system technology, used in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as harmful and high-risk corrosive gas sealing, and achieve the effects of test specifications, convenient installation, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

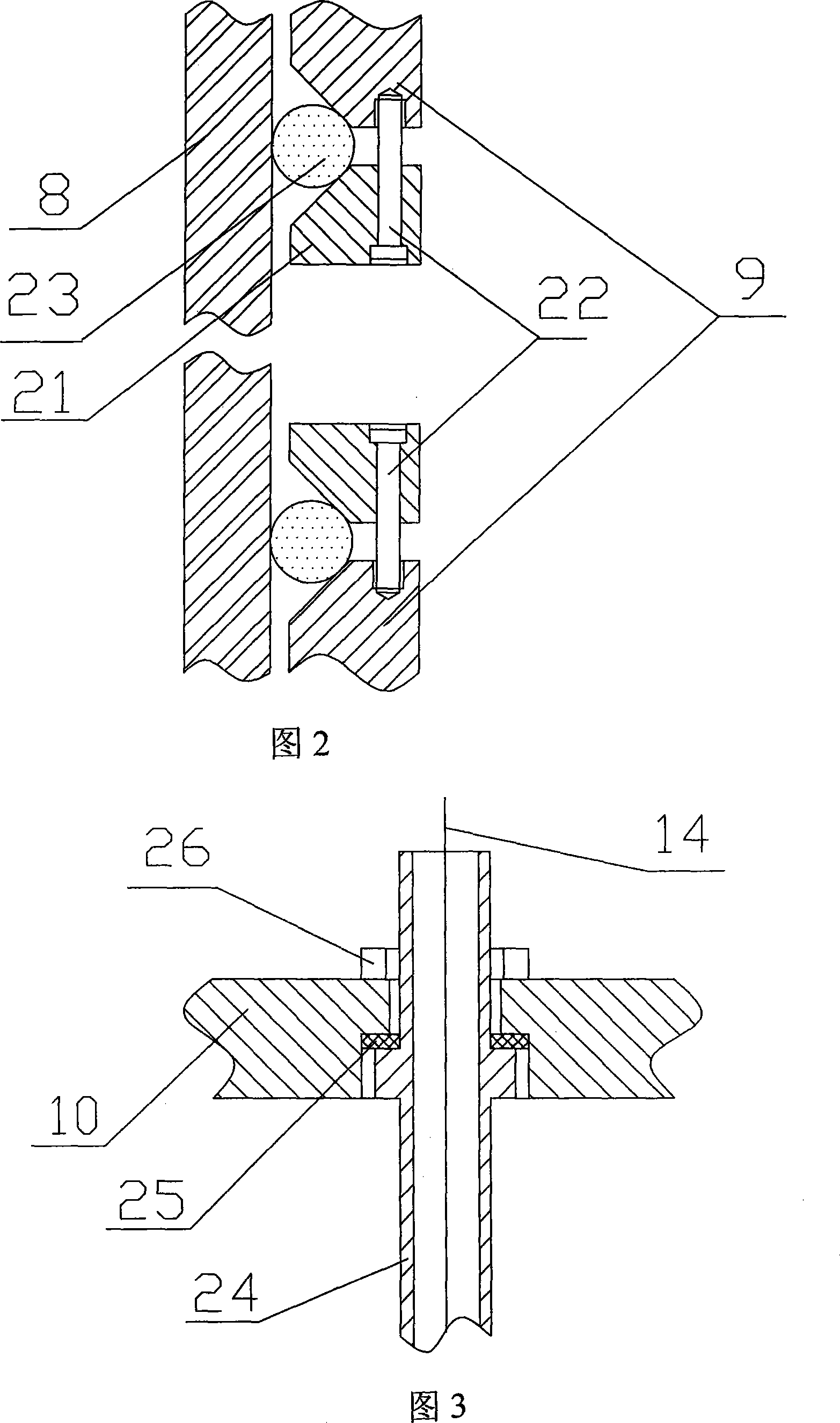

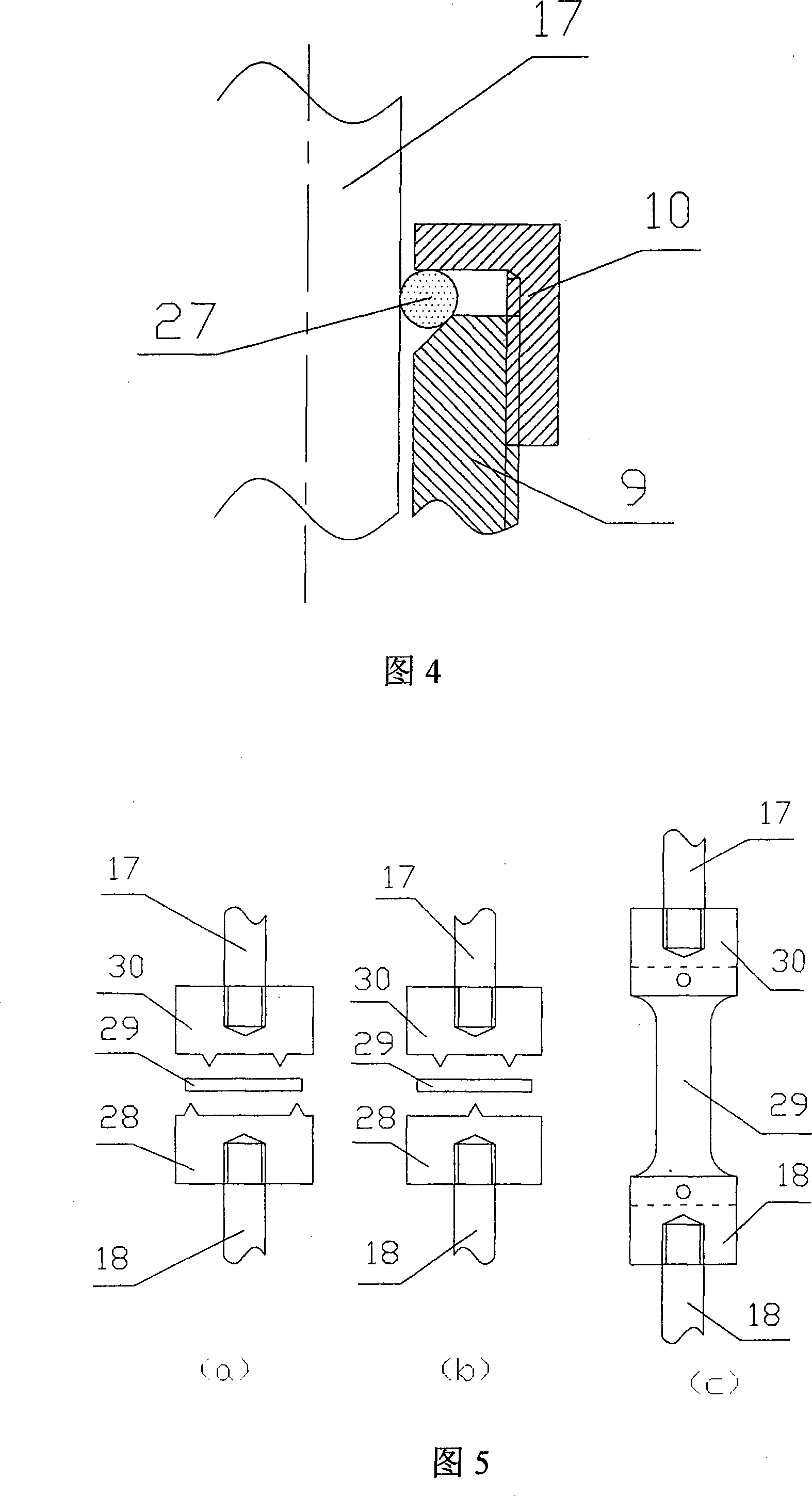

[0021] The installation of the test device of the present invention: assemble the base 1 in order, the column 2, the upper support plate 7, the lower support plate 3, the lower sealing sleeve 4, and then the electric heating furnace 6 is installed on the column 2 through the connecting element 5, and the lower support rod 18 is installed on the lower sealing sleeve 4, the sample is placed on the lower support seat, and then the quartz tube 8 is placed on the lower sealing sleeve, after the upper support seat is installed on the upper support rod, it is placed on the sample, and finally the upper support The sealing sleeve is installed on the upper end of the quartz tube. The upper sealing sleeve 9 and the lower sealing sleeve 4 are respectively connected with the upper support plate 7 and the lower support plate 3 through four locking bolts. Screw on the upper sealing sleeve 9 after the upper support rod sealing cap 10 is packed into the O-ring. When loading, the weight 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com