Water-based 6H-SiC monocrystalline substrate chemical mechanical polishing (CMP) solution and preparation method thereof

A chemical-mechanical, polishing liquid technology, used in polishing compositions containing abrasives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

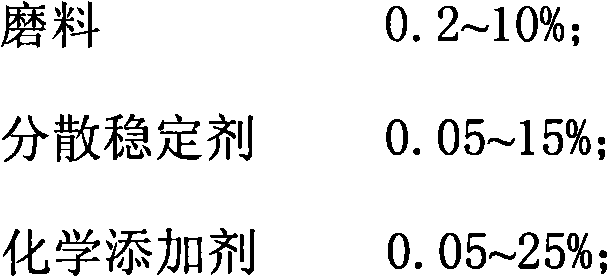

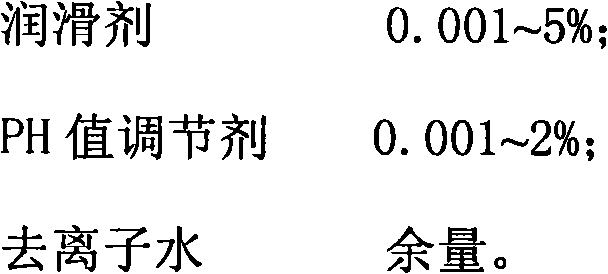

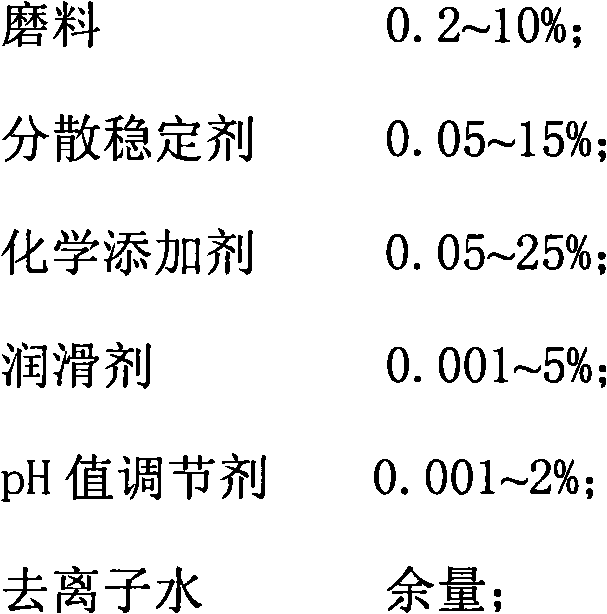

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Taking the preparation of 500ml chemical mechanical polishing liquid as an example, the dispersion stabilizer nonylphenol polyoxyethylene ether and deionized water are used to prepare a 300ml deionized water mixed solution, wherein the weight percentage of nonylphenol polyoxyethylene ether 0.3%, for later use; take 100ml of silica sol with an average particle size of 25nm and add it to the mixed solution made of nonylphenol polyoxyethylene ether and deionized water, and stir evenly, then add 2g of 150nm diamond powder, and stir Evenly, then add 2g of 1~5nm lubricant and stir evenly. Then add an appropriate amount of deionized water to 490ml; then add 10ml of hydrogen peroxide, stir evenly, and finally add triethanolamine as a pH regulator to adjust its pH to 11.

[0028] Use the above-mentioned prepared polishing solution to polish the Si surface of 2-inch 6H-SiC single wafer (0001) on a ZYP300 polishing machine. Before polishing, the surface roughness is abo...

Embodiment 2

[0029] Embodiment 2: Taking the preparation of 500ml chemical mechanical polishing liquid as an example, use dispersant nonylphenol polyoxyethylene ether and deionized water to prepare a 300ml deionized water mixed solution, wherein the weight percentage of nonylphenol polyoxyethylene ether is 0.4%, for later use; take 100ml of silica sol with an average particle size of 25nm and add it to the mixed solution of nonylphenol polyoxyethylene ether and deionized water, and stir evenly, then add 3g of 250nm diamond powder, and stir evenly , and then add 2g of 1 ~ 5nm lubricant, stir well. Then add an appropriate amount of deionized water to 490ml; then add 10ml of hydrogen peroxide, stir evenly, and finally add triethanolamine as a pH regulator to adjust its pH to 9.5.

[0030] Polish a 2-inch 6H-SiC single wafer (0001) C surface on a ZYP300 polishing machine with the above-mentioned prepared polishing solution. Before polishing, the surface roughness is about 90nm. The polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com