Oil field sewage bactericide and preparation method thereof

A technology of oilfield sewage and fungicides, which is applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of high cost and difficulty in lasting drug effect, and achieve the goal of lasting drug effect, slowing down the operation intensity, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

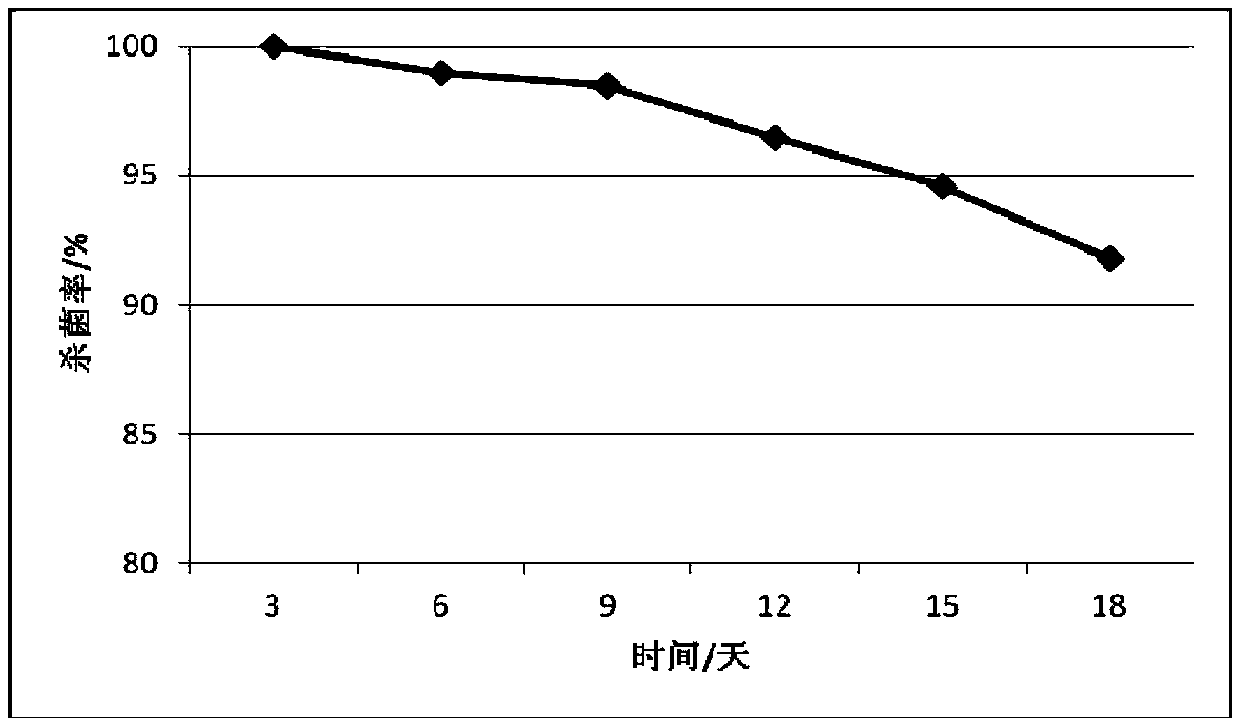

[0022] Example 1: Add 10g of nano titanium dioxide powder and 57mL of distilled water into a 250mL reaction vessel, add 1mL of ethylene glycol with a mass fraction of 99%, heat to 70°C, stir for 1.5 hours, and then add 12mL of 50% dodecyl Alkyl dimethyl benzyl ammonium chloride and 20 mL of sodium hypochlorite solution with a mass fraction of 30% are stirred evenly to obtain a fungicide for oilfield sewage. For performance evaluation results, see figure 1 .

Embodiment 2

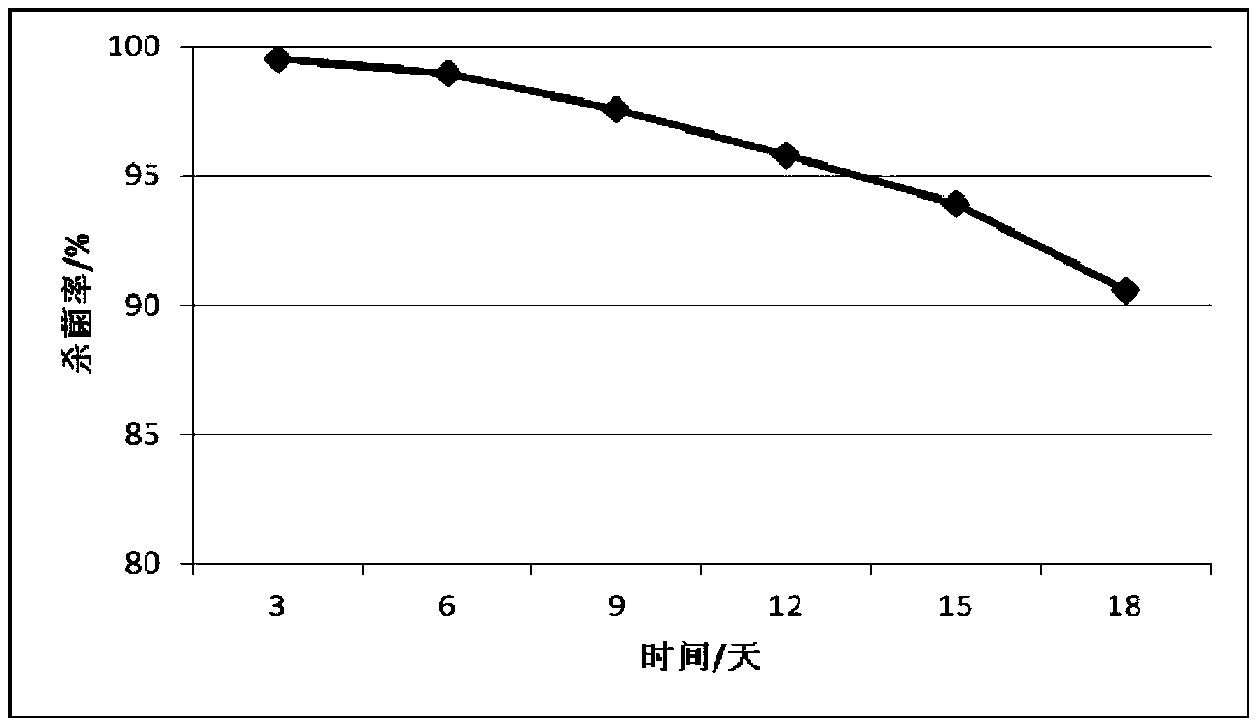

[0023] Example 2: Add 15g of nano-titanium dioxide powder and 45mL of distilled water into a 250mL reaction vessel, add 3mL of epichlorohydrin with a mass fraction of 30%, heat to 60°C, stir for 1 hour, and then add 20mL of dec Dialkyl dimethyl benzyl ammonium chloride and 17 mL of potassium hypochlorite solution with a mass fraction of 30% were stirred evenly to obtain a fungicide for oilfield sewage. For performance evaluation results, see figure 2 .

Embodiment 3

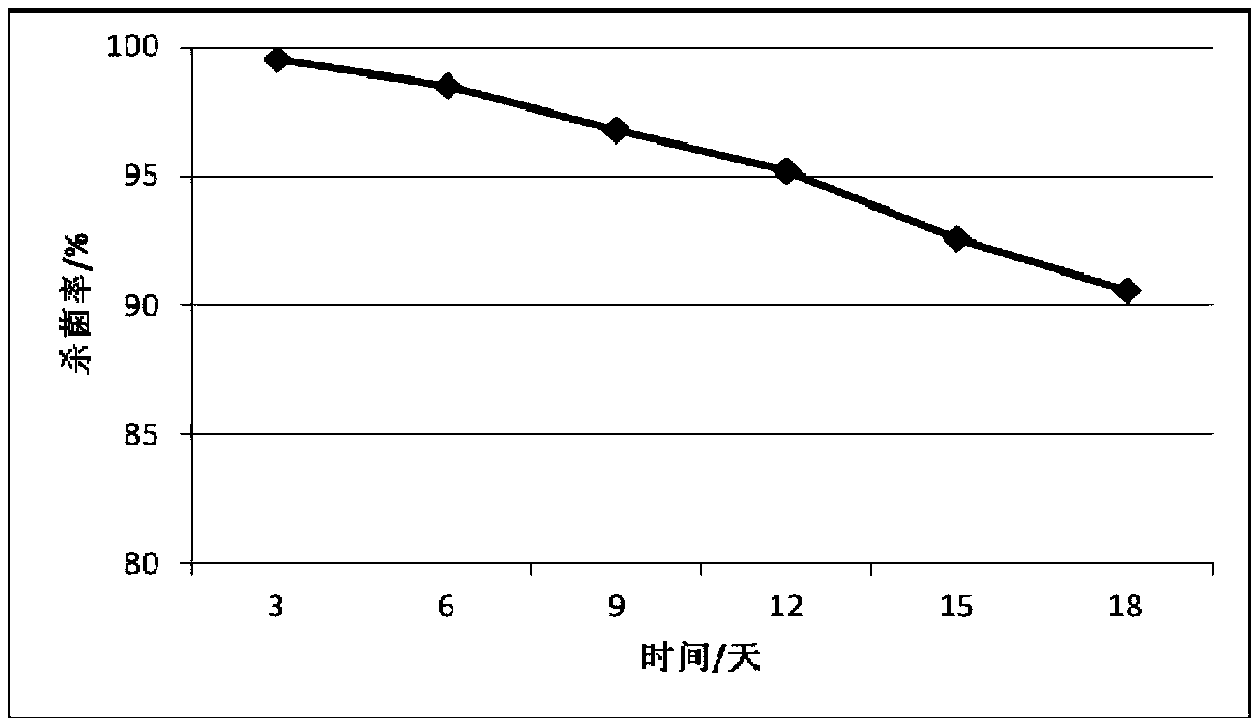

[0024] Example 3: Add 25g of nano titanium dioxide powder and 35mL of distilled water into a 250mL reaction vessel, add 5mL of 4-mercaptobenzoic acid with a mass fraction of 30%, heat to 80°C, stir for 1 hour, and then add 10mL of 4-mercaptobenzoic acid with a mass fraction of 50%. Octadecyl dimethyl benzyl ammonium chloride and 25mL sodium hypochlorite solution with a mass fraction of 30% were stirred evenly to obtain the oilfield sewage fungicide. For performance evaluation results, see image 3 .

[0025] The test method is unchanged, and the content of each component is changed. At a temperature of 70 ° C, Examples 4-10 are obtained under the condition of stirring for 1 hour. The results are as follows:

[0026] Table 1 Composition and content of oilfield sewage fungicides in Examples 4-10

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com