Method for testing concrete performance under pressure stress-chemical coupling effect and device thereof

A test method and technology for concrete specimens, which are used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc. The effect of low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

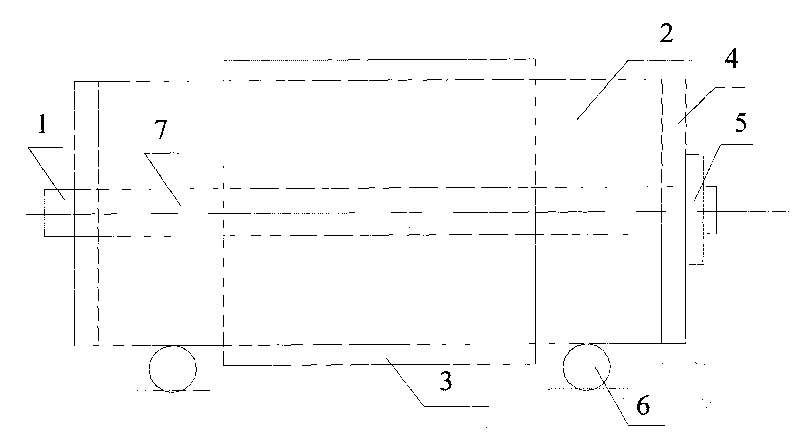

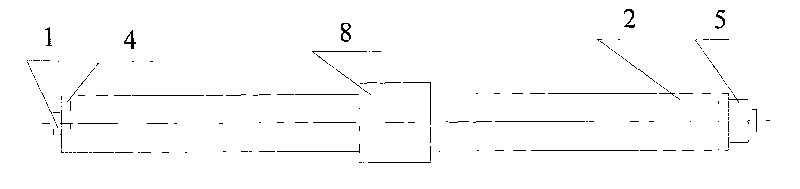

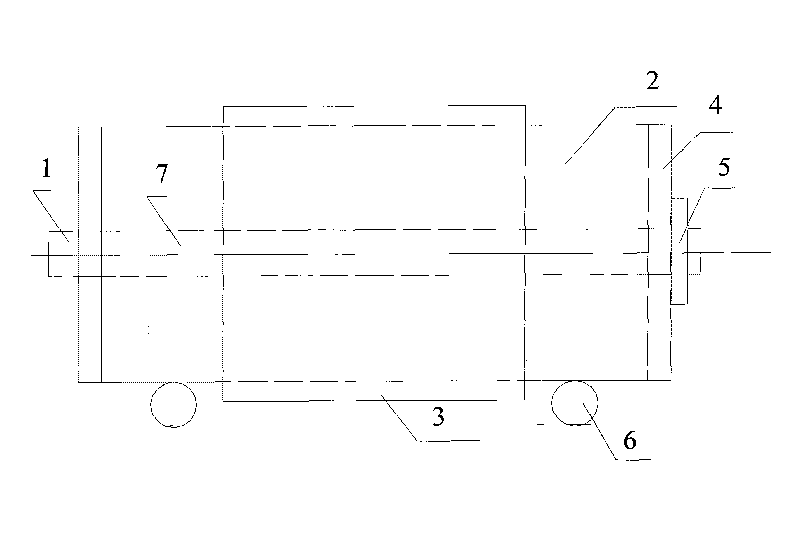

Image

Examples

Embodiment 1

[0029] The first step, the calculation of steel bar strength requirements:

[0030] Assuming the section A of the concrete, in this example, take 100×100mm 2 , then the smaller the diameter of the reserved channel, the smaller the impact on the performance of the concrete specimen under compression. Assume that the diameter of the steel bar is D, the maximum load is P, and the average stress in the section is σ×A. In this example, 400KN is used for calculation, then The design value f of the tensile strength of the reinforcement must be greater than If the diameter of the steel bar is 25mm, then there are

[0031] f > P π D 2 / 4 = 400000 / ( 3.14 * 25 * 25 / 4 ) = 816 MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com