Mechanical descaling method

A mechanical and brush roller technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that the uniformity of cleaning is difficult to be guaranteed, the stability of the effect of the brush roller is affected, and the hard particles are easy to fall off, etc. , achieve good environmental protection improvement ability, improve environment and pollution control ability, and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

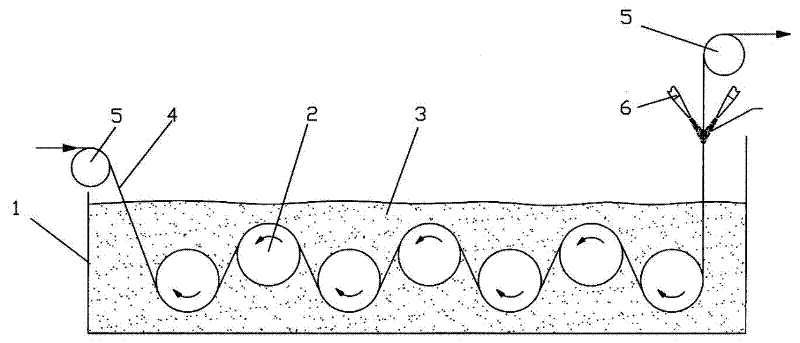

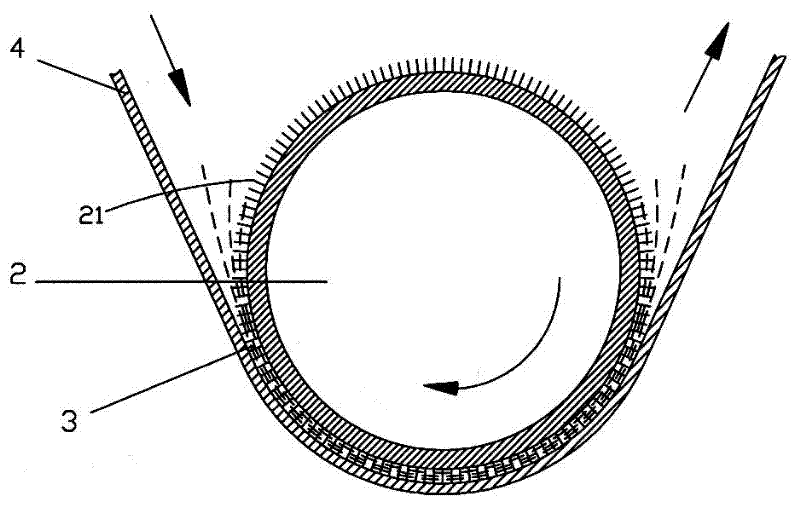

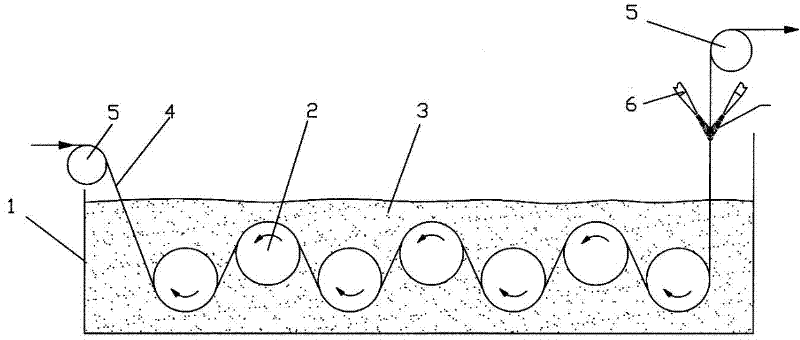

[0019] See figure 1 , figure 2 , A mechanical descaling method of the present invention, in a mud pool 1 filled with grinding mud, several brush rollers 2 arranged staggered up and down, the brush rollers 2 are completely immersed in the grinding mud 3, and the surface of the brush roller 2 has bristles 21; Insert the metal strip 4 in the brush rollers 2 staggered up and down, and use the tension of the front and rear tension roller groups 5 to produce a certain tension between the metal strip 4 and all the brush rollers 2, That is, a certain contact pressure is generated; the metal plate belt moves under the pulling action of the front and rear tension roller groups, and the brush roller rotates in the opposite direction to realize the relative movement between the brush roller surface and the metal plate belt surface. There is a large amount of grinding mud in the bristles. When the bristles slide relative to the surface of the metal strip, the mud also slides and grinds rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com