Carbon fiber unfolding device

A technology of carbon fiber and carbon fiber bundle, which is applied in the field of carbon fiber yarn spreading device, can solve the problems of carbon fiber spreading effect, uneven heating of carbon fiber bundle, etc., and achieve good fiber spreading effect, low invention cost and low equipment investment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

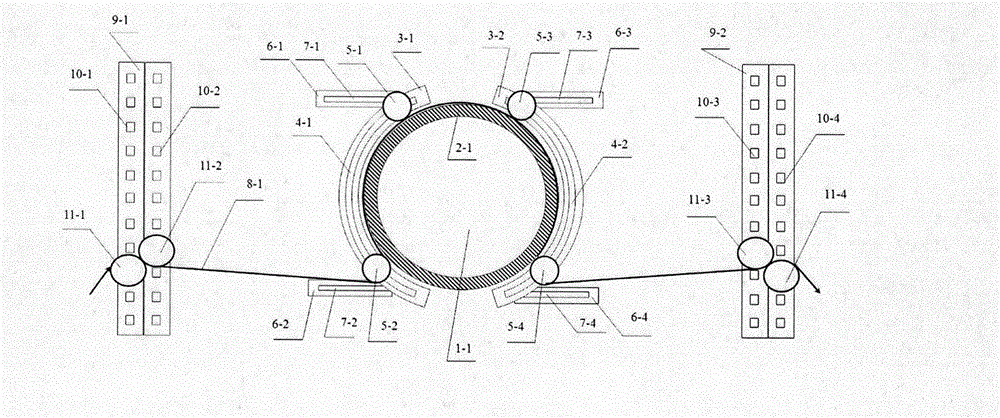

[0018] Attached below figure 1 The present invention is described in further detail, see attached figure 1 .

[0019] attached figure 1 It is a schematic diagram of a carbon fiber spreading device of the present invention: the carbon fiber bundle (8-1) is introduced into the carbon fiber spreading device through the action of a pair of tangential guide rollers (11-1 and 11-2) on the support (9-1) In the second yarn guide roller (5-2), after the carbon fiber bundle bypasses the heating roller (1-1) and its heating ring (2-1), it is drafted to the support by the fourth yarn guide roller (5-4) (9-2) put on a pair of tangential guide rollers (11-3 and 11-4), and then carry out subsequent process processing; wherein the carbon fiber bundle is adjusted by adjusting the guide rollers (5-1) and The distance of the guide roller (5-2) and the distance between the guide roller (5-3) and the guide roller (5-4) control the heating area of the carbon fiber bundle on the heating roller;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com