Fiber extending method for carbon fibers through supersonic wave

An ultrasonic and carbon fiber technology, applied in fiber processing, textile and papermaking, physical processing, etc., can solve the problems of a large decline in the mechanical properties of carbon fiber, affecting the use of carbon fiber, slow speed, etc., achieving good fiber spreading effect, low cost of invention, The effect of enhancing the fiber spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

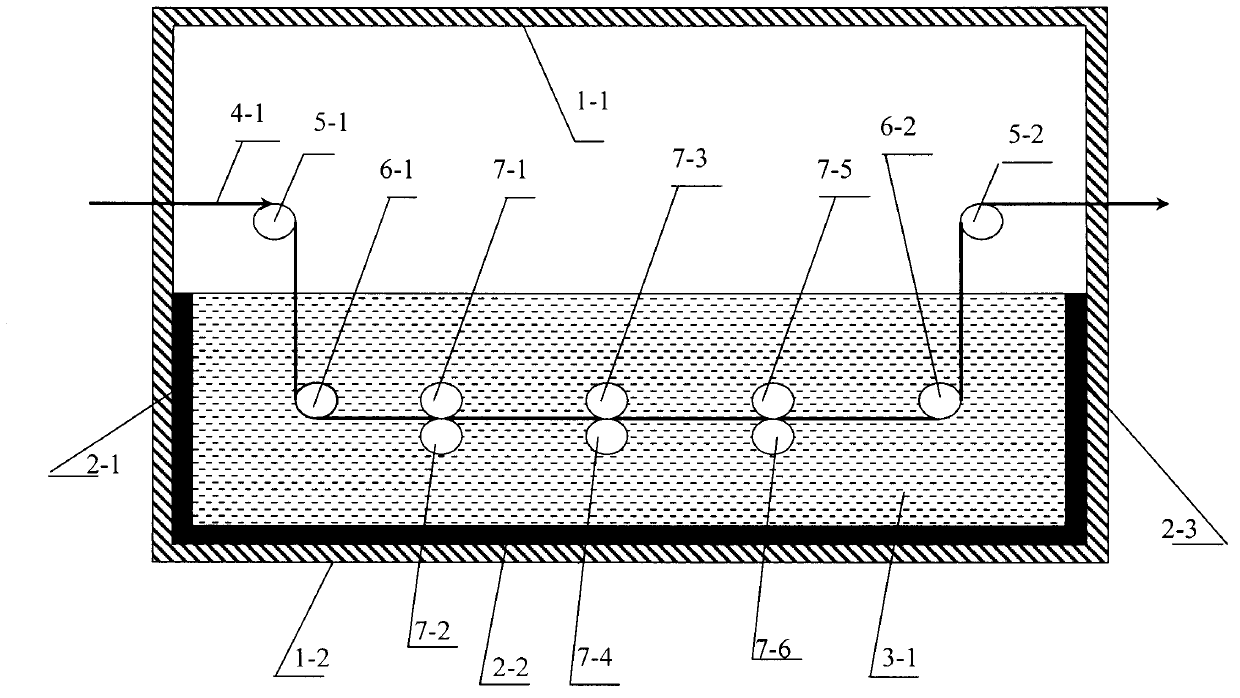

[0019] Embodiment 1 adopts the sodium hydroxide solution that concentration is 15wt%, and ultrasonic power is 2000W, and ultrasonic frequency is 100kHz, and the tangential drafting guide roll in solution is 3 pairs, and drafting speed is 0.8m / s to stretch carbon fiber bundle. fiber.

Embodiment 2

[0020] Example 2 uses an ethanol solution with a concentration of 30wt%, with an ultrasonic power of 2500W and an ultrasonic frequency of 160kHz. There are 2 pairs of tangential draft guide rollers in the solution, and the draft speed is 1.5m / s to spread the carbon fiber bundle.

Embodiment 3

[0021] Embodiment 3 adopts the hydrogen peroxide solution that concentration is 20wt%, and ultrasonic power is 1500W, and ultrasonic frequency is 160kHz, and the tangential drafting guide roll in solution is 3 pairs, and drafting speed is 1.2m / s to stretch carbon fiber bundle. fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com