Burr removal method and apparatus for oil ejector body pressure regulating cavity

A pressure regulating chamber and fuel injector technology, which is applied in metal processing equipment, abrasive jet machine tools, abrasives, etc., can solve problems such as surface burrs and oxides, and achieve environmental protection, uniform grinding, and high processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

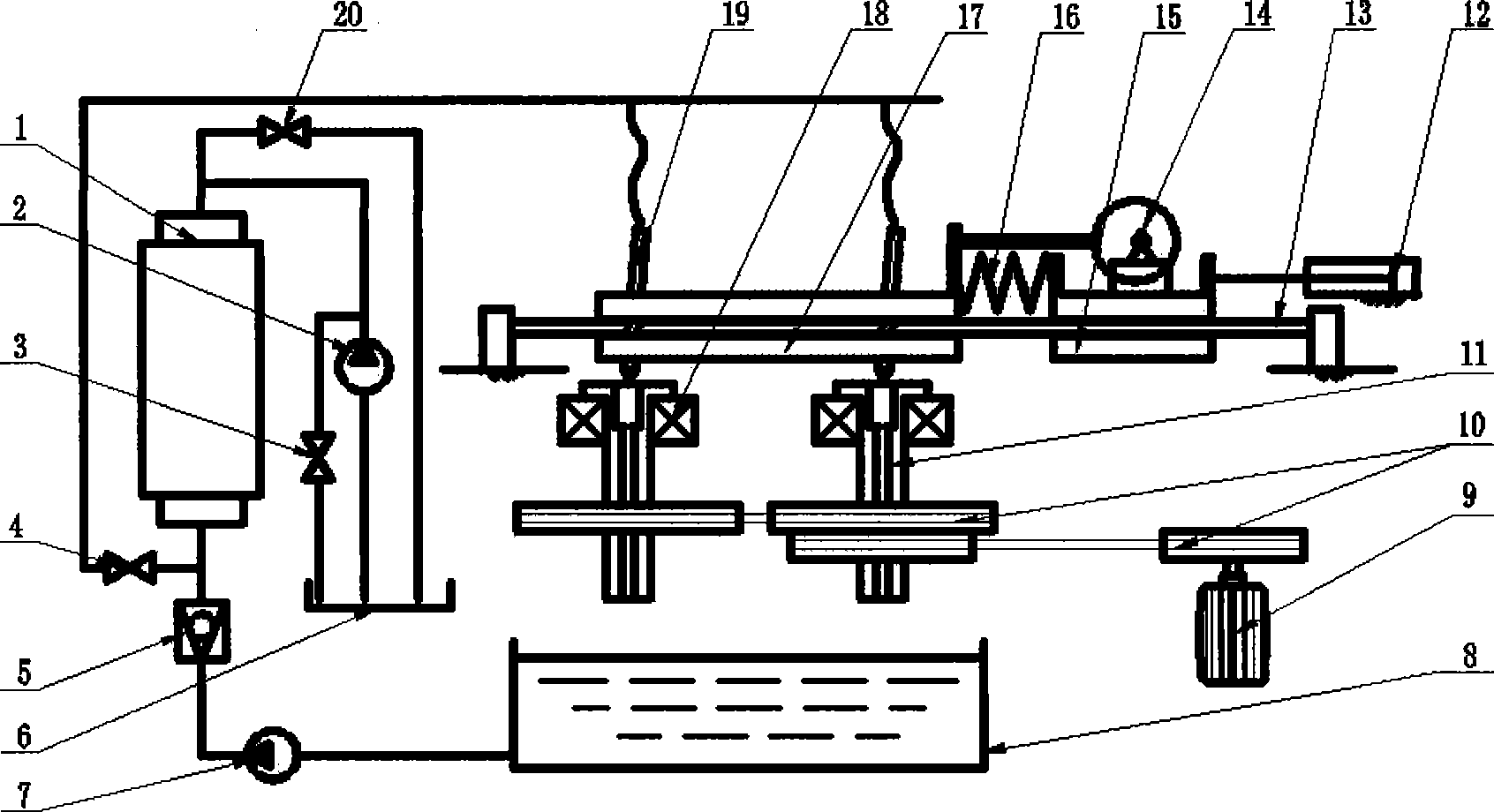

[0015] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0016] The method for deburring the pressure regulating chamber of the injector body adopts the abrasive slurry jet to deburr, and uses the high-pressure generating device to make the abrasive slurry generate a high-speed jet. The abrasive particles with relatively large kinetic energy in the abrasive slurry jet have a strong grinding effect Through the erosion and grinding effect of these abrasive particles on the inner wall of the channel of the pressure regulating chamber of the injector body, the burrs and oxides on the surface of the inner wall of the channel of the pressure regulating chamber of the injector body are removed.

[0017] see figure 1 , the equipment for deburring the pressure regulating cavity of the injector body used in this method includes a high-pressure material tank 1, an oil pump 2, a nozzle 19, a slurry pump 7, a slide rail 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com