Water-milling environmental-friendly polishing wheel and manufacturing method thereof

A polishing wheel, environmental protection technology, applied in the field of polishing wheels, can solve the problems of poor toughness, insufficient gloss, not beautiful and delicate knife handles, etc., and achieve the effect of good structural toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

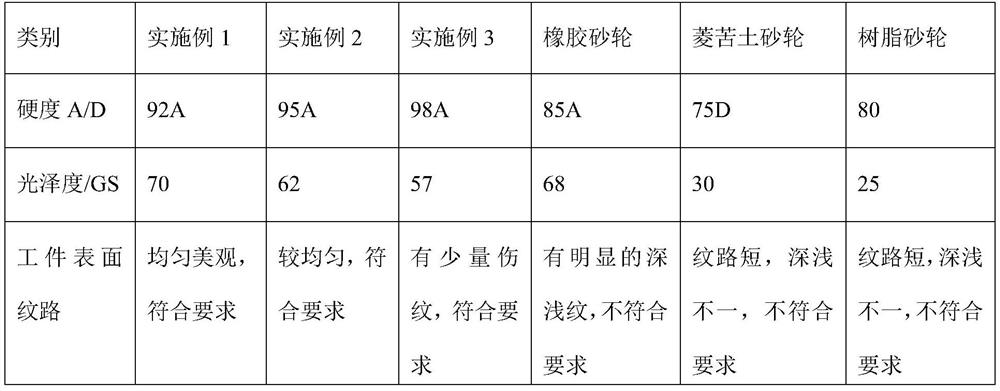

Examples

Embodiment 1

[0031] The water-grinding environment-friendly polishing wheel of the present embodiment comprises the following components by weight:

[0032] 30 parts of polyether polyol (functionality 2, molecular weight 2000), polyester polyol 20 parts (functionality 3, molecular weight 4000), TDI 25 parts, triethylenediamine 0.035 parts, 1,4-butanedi 4 parts of alcohol, 0.6 parts of water, 0.2 parts of foam stabilizer of product number M-7742 of Jiangsu Meisid Chemical Co., Ltd., 120 parts of black silicon carbide (particle size is 80#-1000#), 7 parts of talcum powder, chrome green 0.7 parts.

[0033] When preparing the polishing wheel, the raw materials of each component are poured into the mold, the mold is heated to 35-45°C, the material in the mold is naturally foamed, and then demolded;

[0034] Heat and bake to cure the polyurethane resin to obtain a semi-finished polishing wheel; the baking temperature during curing is 80-120°C, and the baking time is 1-3 hours. After curing, the...

Embodiment 2

[0037] The water-grinding environment-friendly polishing wheel of the present embodiment comprises the following components by weight:

[0038] 35 parts of polyether polyol (functionality 3, molecular weight 5000), polyester polyol 15 parts (functionality 2, molecular weight 2000), MDI 35 parts, tetramethylhexamethylenediamine 0.025 parts, ethylene glycol 3 parts , 0.4 parts of cyclopentane, 0.4 parts of foam stabilizer with product number M-88310 of Jiangsu Meisid Chemical Co., Ltd., 180 parts of boron nitride (particle size is 80#-1000#), 9 parts of calcium carbonate, iron red powder 0.8 servings.

[0039] The preparation method of the polishing wheel of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0041] The water-grinding environment-friendly polishing wheel of the present embodiment comprises the following components by weight:

[0042] 40 parts of polyether polyol (functionality 3, molecular weight 3500), polyester polyol 10 parts (functionality 2, molecular weight 5000), PPDI 45 parts, triethylamine 0.015 parts, methyldiethanolamine 2 parts, 1 , 0.2 parts of 1-difluoroethane, 0.6 parts of foam stabilizer with product number M-9905 of Jiangsu Mesid Chemical Co., Ltd., 240 parts of zirconium corundum (particle size is 80#-1000#), 11 parts of calcium stearate parts, 0.9 parts of carbon black.

[0043] The preparation method of the polishing wheel of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com