Soil pressing roller with adjustable pressing force and manufacturing method thereof

A production method and adjustable technology, applied in the field of agricultural machinery, can solve problems such as different pressure requirements, and achieve the effect of large market demand, easy molding, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

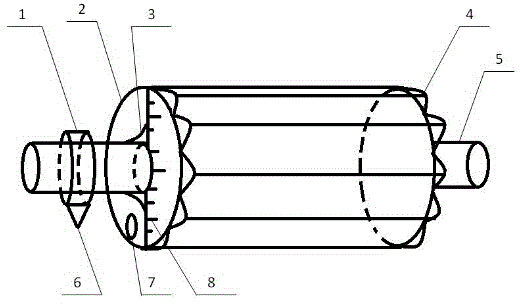

[0024] like figure 1 As shown, a pressure-adjustable soil pressure roller includes a roller body 2, the roller body is a plastic roller body or a rubber roller body, the roller body is a hollow cylinder structure, the wall thickness of the roller body is 5mm, the end diameter is 80cm, and the length is 150cm . The end surface of the roller body is provided with a water injection hole 7 with a diameter of 10 cm, and the water injection hole orifice is provided with a sealing cover to seal it.

[0025] The end surface of the roller body is provided with a scale line 8 marking the weight, and the outer circumferential surface of the roller body is axially provided with several arc-shaped convex lines 4, the tops of adjacent arc-shaped convex lines are separated by 5 cm, and the height of the arc-shaped convex lines is 5 cm.

[0026] The two ends of the roller body are provided with traction shafts 5 available for traction respectively. The diameter of the traction shaft is 15cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| End diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com