Diamond super micro powder and preparation method thereof

The technology of diamond micropowder and ultrafine powder is applied in the field of abrasives, which can solve the problems that the grinding force and surface flatness requirements of diamond particles cannot be solved, the hydrophilicity and lipophilicity of nano-diamond particles are changed, and the price of product raw materials is high. Machined surface flatness, obvious cost advantage, the effect of less cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 A kind of preparation method of diamond ultrafine powder, comprises the following steps:

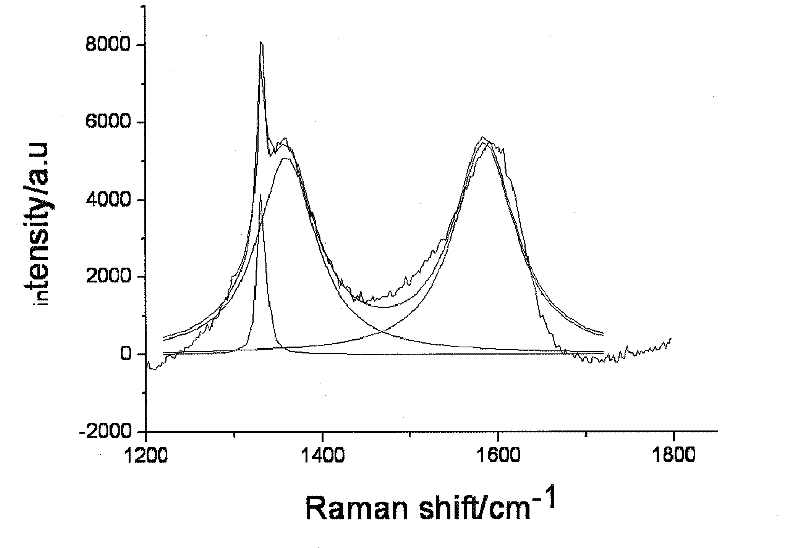

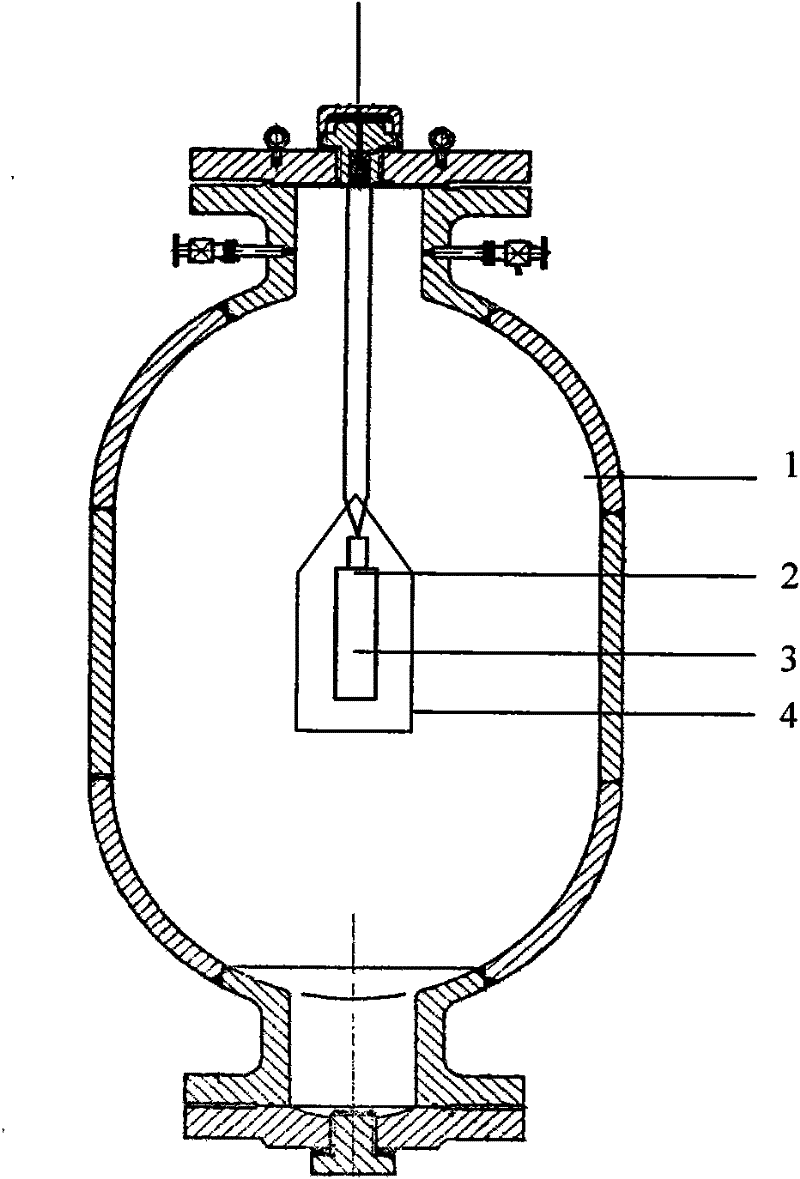

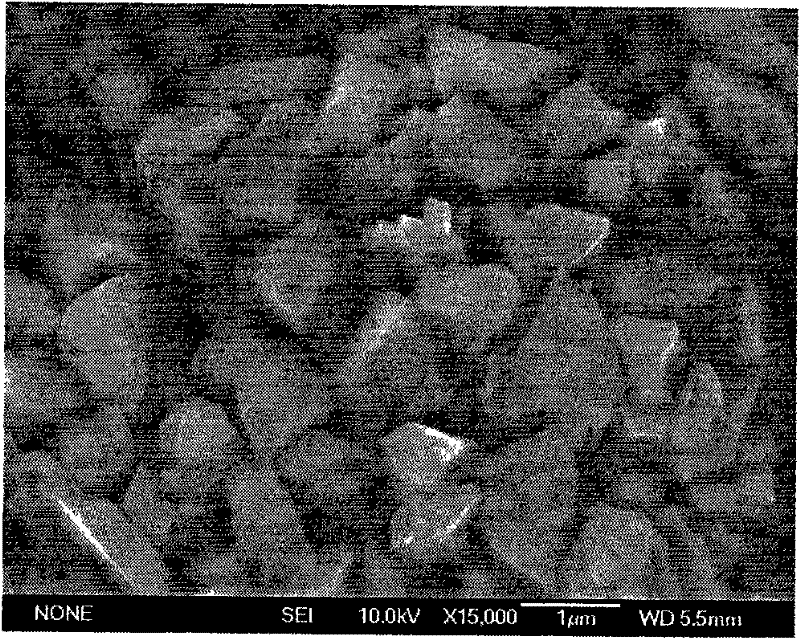

[0046] (1) The explosive assembly takes the single crystal diamond micropowder synthesized by isostatic pressing with a specification of 3 microns (for its crystal shape, appearance and phase, refer to figure 2 , image 3 ), mix together according to diamond micropowder+TNT explosive+additive (paraffin)=400g+600g+30g, put into mold after stirring evenly, make the cylindrical powder column of length-to-diameter ratio=3; tank (see figure 1 ), the powder column is protected by a water jacket;

[0047] (2) Explosive synthesis connects the detonator to assemble the explosive device for explosive action, collects the explosive products, removes mechanical impurities through sieving, and obtains a diamond blank;

[0048] (3) Unless carbon impurities are dissolved in dilute nitric acid to remove metal impurities, then washed with pure water to near neutrality and dried, a...

Embodiment 2

[0049] Embodiment 2 A kind of preparation method of diamond ultrafine powder, comprises the following steps:

[0050] (1) Explosive assembly gets 300g of 1 micron specification isostatic pressing synthetic single crystal diamond micropowder abrasive, puts into mold after mixing evenly according to diamond micropowder+TNT explosive+additive (paraffin)=300g+700g+20g, makes length-to-diameter ratio =3 cylindrical powder column. Put the finished powder into the figure 1 In the explosion tank shown, the powder column is protected by a water jacket;

[0051] (2) Explosive synthesis connects the detonator to assemble the explosive device for explosion, collects the explosive products, removes mechanical impurities through sieving, and obtains a diamond blank;

[0052] (3) Unless carbon impurities are dissolved in dilute nitric acid to remove metal impurities, washed with pure water to near neutrality, and dried, a large number of microscopic internal cracks and structural defects a...

Embodiment 3

[0053] Embodiment 3 A kind of preparation method of diamond ultrafine powder, comprises the following steps:

[0054] Steps (1), (2), (3) are the same as in Example 1;

[0055] (4) Purification Take 100g of the product obtained in the previous step and place it in a 1000ml heat-resistant flask, add 100ml of nitric acid and 400ml of perchloric acid, place the flask on a temperature-controlled electric heating plate and heat it until the solution boils, and keep it for 2 hours, then remove it to cool , washed with high-purity water, the pH value is close to neutral, and the gray-black micropowder is obtained after drying, and the metal impurities are measured by inductively coupled plasma emission spectrometry (ICP-AES). The contents of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com