Floating tool electrolytic turning and grinding integrated machining method and implementation device

A technology of floating tools and processing methods, which is applied in the direction of electric processing equipment, attachments, manufacturing tools, etc., and can solve the problems of difficult stable adjustment of grinding force, reduced service life, and difficult complete removal of mechanical grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

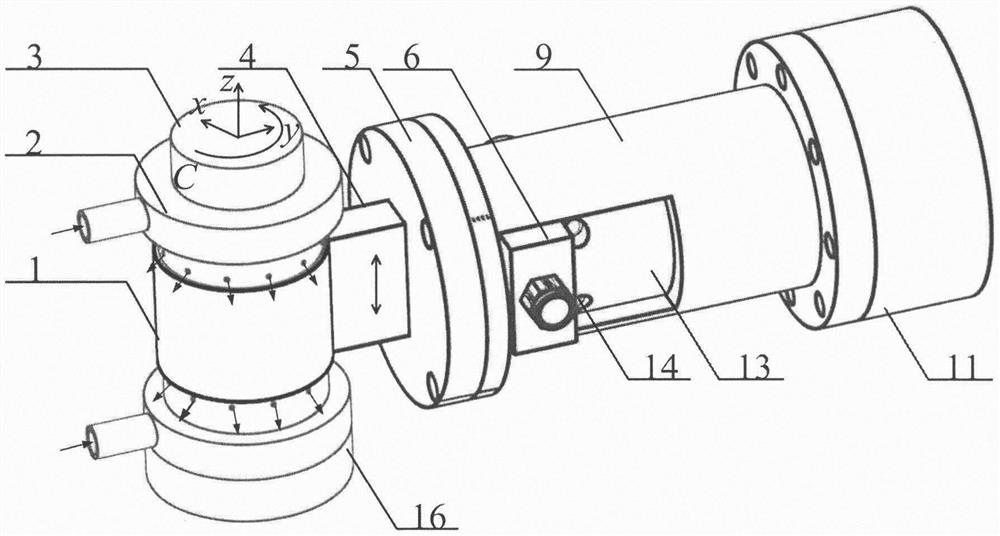

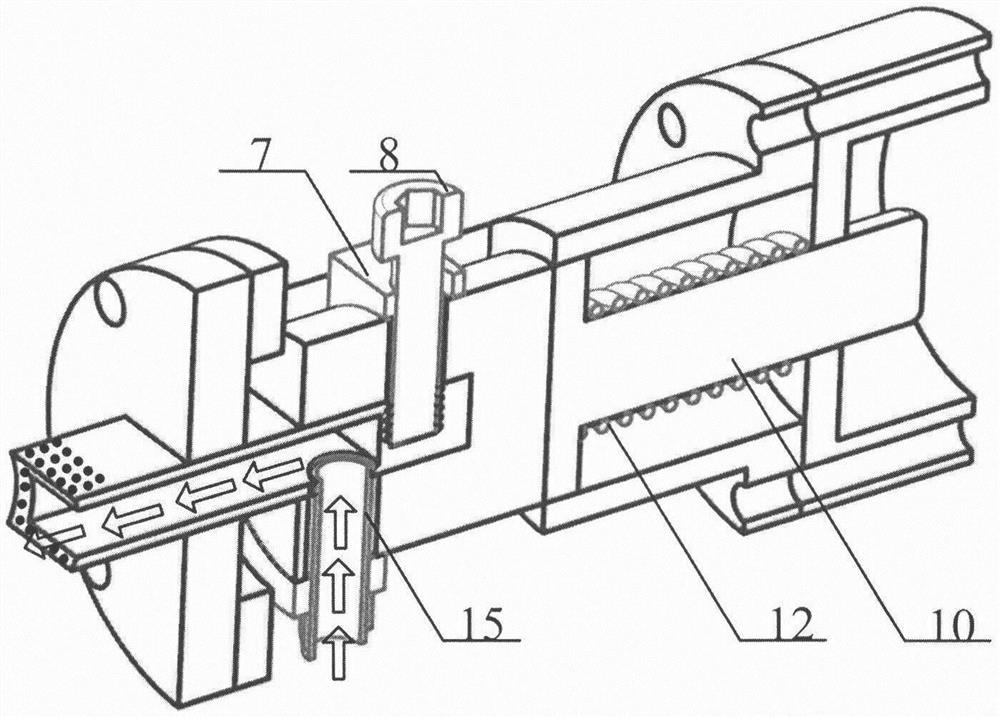

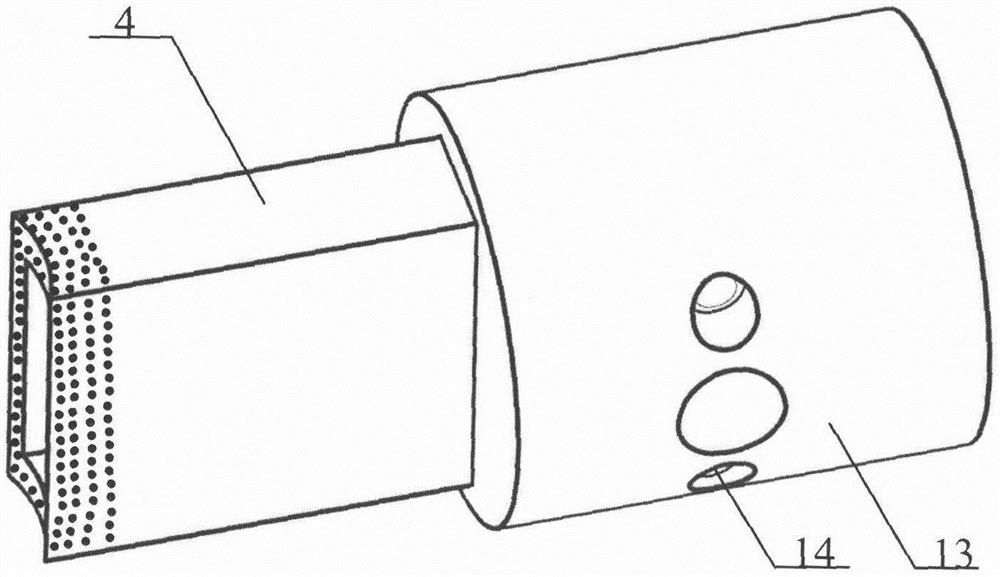

[0022] like figure 1 Shown is the overall structure of the floating tool electrolytic turning and milling integrated processing realization device, which includes: current and drainage devices, tooling fixtures, rotary ventilation device 2, rotary workpiece 1 and tool grinding head 4. The rotary workpiece 1 is installed on the rotary shaft 3, and rotates around its own axis; the rotary ventilation device 2 is respectively arranged on the upper and lower sides of the rotary workpiece 1, and the mover end of the rotary ventilation device 2 performs rotary motion with the rotary shaft 3 , The stator end is connected with the air compressor, and the high-pressure air is continuously transported to the non-processing area of the rotary workpiece 1 through the air outlet holes evenly distributed on the side wall of the rotary ventilation device 2; a rotary conductive slip ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com