Electronmagnetic clutch

An electromagnetic clutch and electromagnetic force technology, which is applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of a large number of components and a large number of man-hours in electromagnetic clutches, and achieve the effect of reducing impact and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

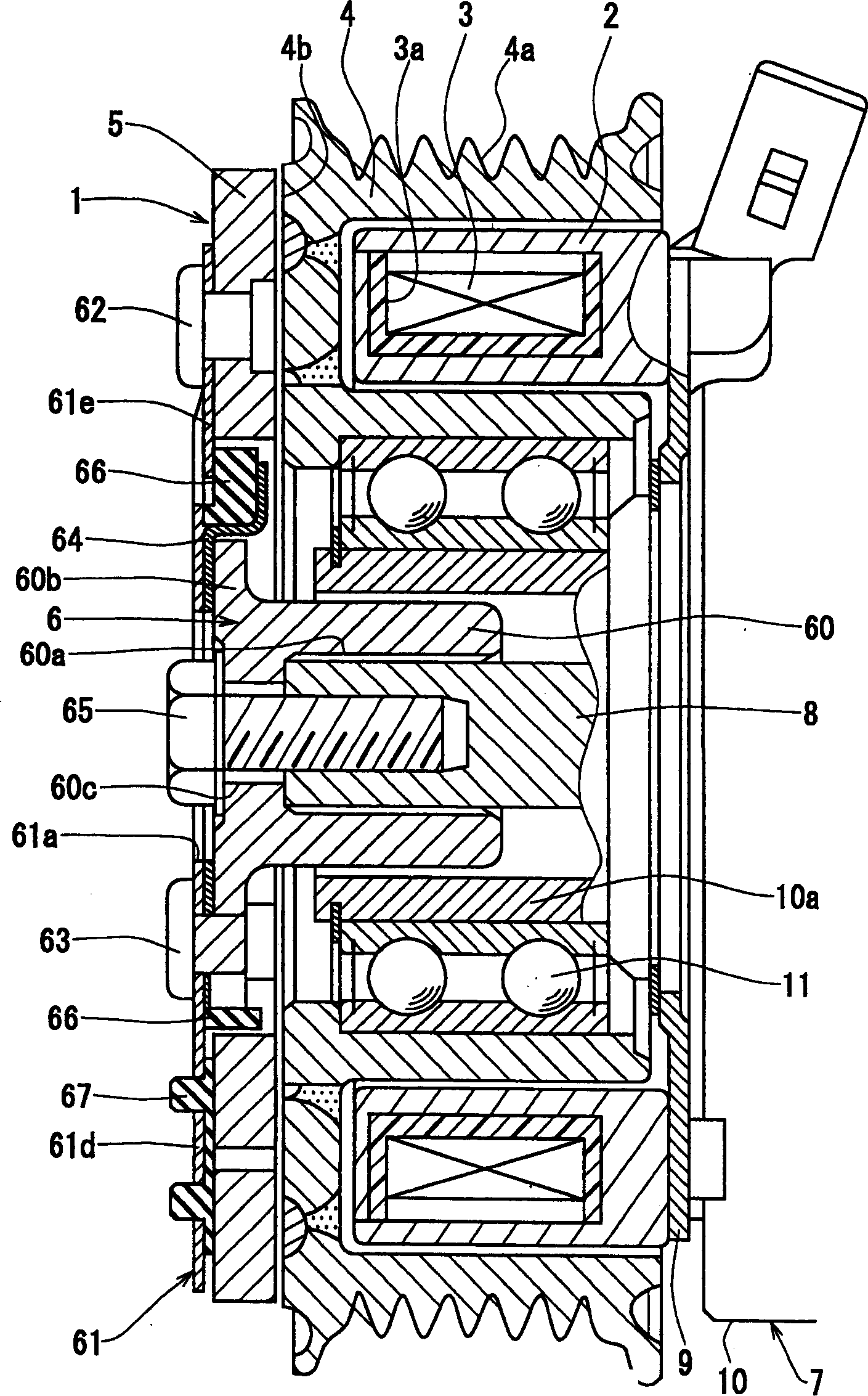

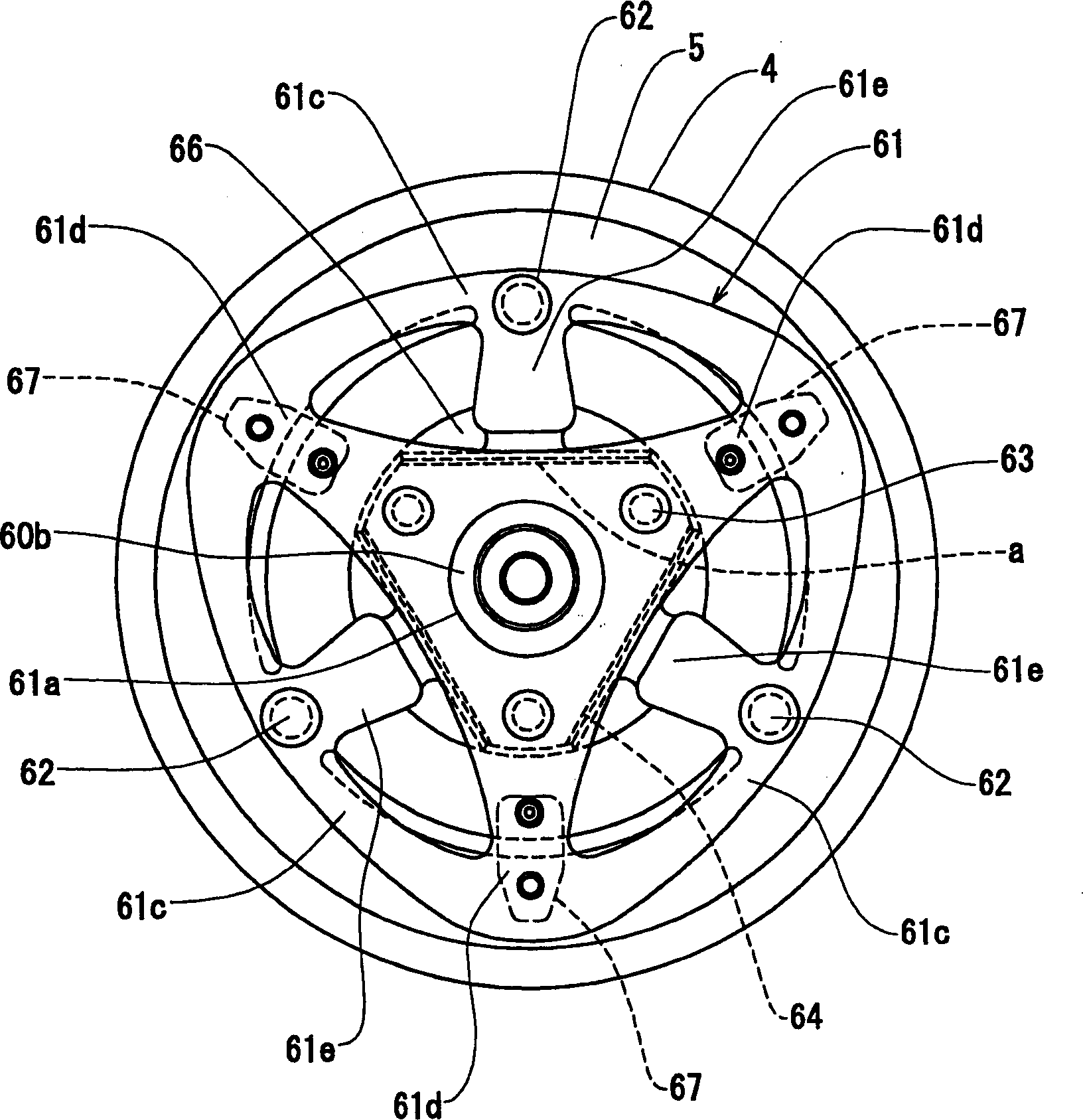

[0072] In the first embodiment described above, the first elastic member 67 and the second elastic member 66 are both separate elements, but the first elastic member 67 and the second elastic member 66 may be integrated. By referring to FIGS. 9 to 11, the second embodiment will be explained. Reference attached Figure 9A with 9B According to the second embodiment, the second elastic member 66 is provided with three integrally formed protrusions 67 which are located at the midpoint in the circumferential direction between the D-shaped elastic members 66a on the second elastic member, and Extend radially outwards.

[0073] Such as Picture 10 with 11 As shown, these protruding parts 67 are arranged between the armature 5 and the leaf spring 61, and are positioned at the midpoint between the fixed parts 62, so as to provide an initial offset for the leaf spring 61, which is equivalent to that in the first embodiment. The first elastic member 67. Therefore, the reduction in the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com