Compression structure for compression forming machine

A technology of compression mechanism and forming machine, which is applied in the direction of material forming presses, presses, stamping machines, etc., can solve the problems of waste of resources, easy blockage, a large number of by-products, etc., to achieve convenient processing and manufacturing, increase input power, The effect of improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

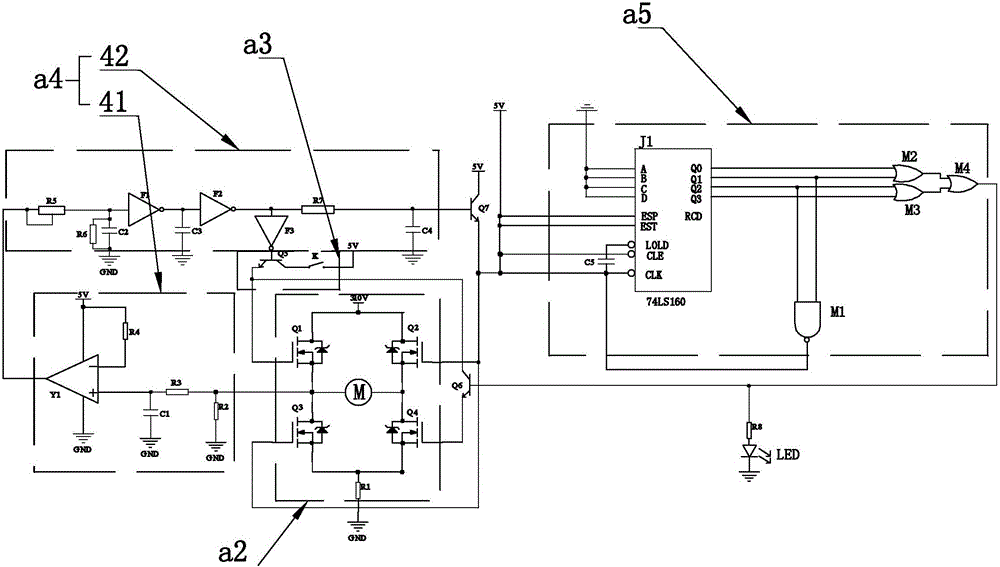

[0035] As an improved specific implementation, the detection circuit a4 includes:

[0036] The current detection unit 41 is coupled to the external motor to detect and output the current flowing through the external motor;

[0037] The delay judgment unit 42 is coupled to the current detection unit 41, and is also coupled to the base of the switch transistor Q7, to receive the motor current signal output by the current detection unit 41, and compare it with the threshold value set in it, if the motor current is greater than threshold, then send a signal to the switch transistor Q7, the switch transistor Q7 conducts the 5V power supply and the control terminal of the IGBT tube Q2 and the control terminal of the IGBT tube Q3. By setting the current detection unit 41, the current flowing through the motor can be effectively detected, and by setting the delay judgment unit 42, the motor current detected by the current detection unit 41 can be delayed and judged. The function of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com