Ultra-high performance concretes having a low cement content

A cement and hydraulic technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as carbon dioxide emissions, and achieve the effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

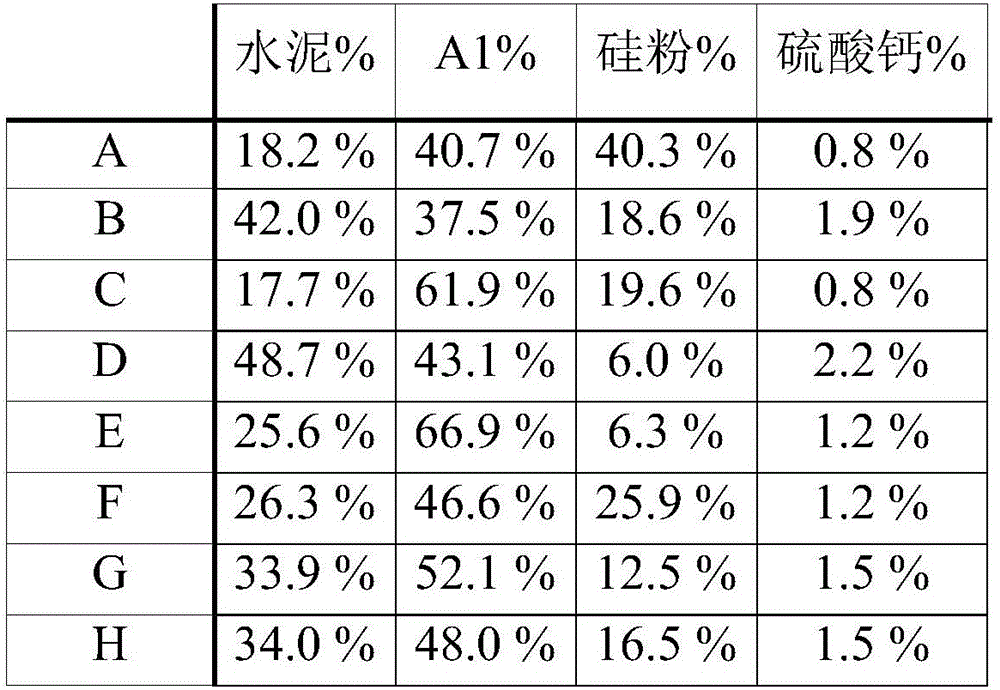

[0127] The invention is described by the following non-limiting examples A, B, C, D, E, F, G, H:

[0128]

[0129]

[0130] The cement was prepared by grinding and isolating Portland cement CEM I, 52.5 NPMES from Lafarge Le Teil Cement Works. This grinding is carried out by using an air jet mill associated with a very efficient separator. The ground cement obtained had a D10 of 1.7 μm, a D50 of 5.3 μm and a D90 of 10.6 μm. Blaine specific surface area is 6,950cm 2 / g and the BET specific surface area is 1.65m 2 / g.

[0131] Le Millisil C6 is a siliceous filler (quartz) from Sibelco. It corresponds to the A1 additive. It has a D10 of 2.9 μm, a D50 of 28.9 μm and a D90 of 95.6 μm.

[0132] Silica fume MST 02 from SEPR is characterized by 12m 2 / g of BET specific surface area.

[0133] Micro A anhydrite is micronized anhydrous calcium sulfate supplied by Maxit. It has a D10 of 1.6 μm, a D50 of 12.3 μm and a D90 of 17.0 μm.

[0134] BE01 sand is siliceous sand supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com