Straightening and winding device applied to tire bead wire production

A technology of winding device and bead steel wire, which is applied in the directions of transportation and packaging, grinding machine tool parts, and conveying filamentous materials, etc. It can solve the problems of single function, simple structure, and no shock-absorbing structure, etc. Tightness, guarantee of applicability, effect of improving torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

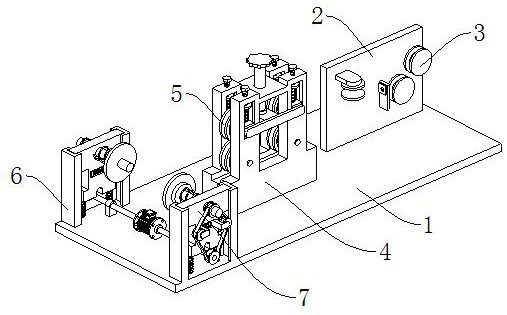

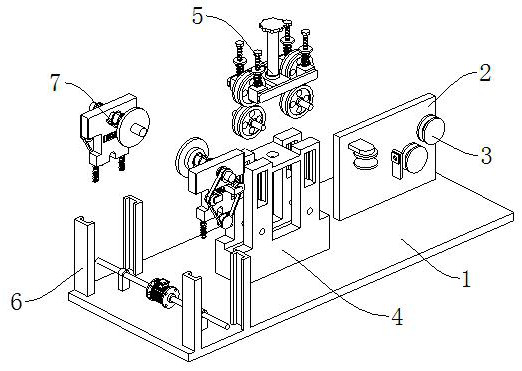

[0030] see Figure 1-3, a straightening and winding device applied to the production of bead wires, comprising a mounting base 1, a mounting plate 2, a fixing frame 4 and a mounting frame 6, the mounting plate 2 is fixedly connected to the mounting base 1, and the mounting plate 2 is connected to There is a steel wire dephosphorization mechanism 3, and the fixed frame 4 is fixedly connected to the middle position of the installation base 1, and the steel wire straightening mechanism 5 is connected to the fixed frame 4; the installation frame 6 is fixedly connected to the end of the installation base 1 away from the installation plate 2, and the installation frame 6 is connected with a driving winding device 7, and the driving winding device 7 includes a driving mechanism and a winding mechanism.

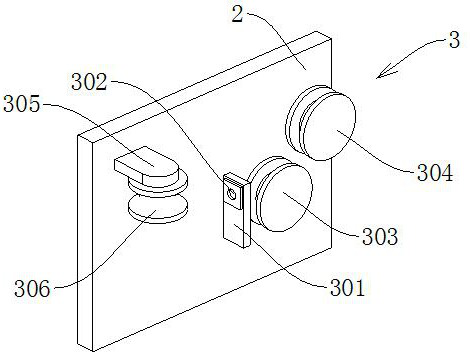

[0031] The steel wire dephosphorization mechanism 3 includes a first connecting plate 301, a first vertical fixed pulley 303 and a second vertical fixed pulley 304, the first connect...

Embodiment 2

[0034] see Figure 4-5 The difference in connection with the basis of Embodiment 1 is that the wire straightening mechanism 5 includes a fixed straightening wheel 501, and the fixed straightening wheel 501 is rotatably connected to the bottom of the fixed frame 4, and the fixed frame 4 is vertically provided with a first Limiting groove 502, vertical sliding connection in the first limiting groove 502 is movable block 503, movable straightening wheel 504 is connected with rotation between movable block 503, and linkage adjustment rod 505 is fixedly connected on the outer wall of movable block 503, linkage adjustment A first fixing plate 506 is fixedly connected between the rods 505 , and a first thread adjusting rod 507 is rotatably connected to the first fixing plate 506 .

[0035] The top of the first fixed plate 506 is provided with a second fixed plate 508, the second fixed plate 508 is fixedly connected with the fixed frame 4, and the first thread adjusting rod 507 is scr...

Embodiment 3

[0038] See 6, based on Examples 1-2 but differing in that,

[0039] The driving mechanism includes a biaxial servo motor 701, which is fixedly installed on the installation base 1, the output shaft of the biaxial servo motor 701 is fixedly connected with a connecting shaft 702, and the installation base 1 is also fixedly connected with an auxiliary support frame 703 , the connecting shaft 702 is rotatably connected to the auxiliary supporting frame 703 .

[0040] The winding mechanism includes a damping spring 704, the bottom of which is fixedly connected to the mounting base 1, the top of the damping spring 704 is fixedly connected to the bottom surface of the movable plate 705, and the movable plate 705 is vertically slidably connected to the mounting frame 6. On the movable plate 705, a second limiting groove 706 is horizontally arranged, the end of the connecting shaft 702 away from the biaxial servo motor 701 is fixedly connected with a first belt pulley 707, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com