Underground horizontal rubbish compressor

A garbage compressor and horizontal technology, which is applied in the directions of presses, trash cans, garbage conveying, etc., can solve the problems of affecting the overall horizontal garbage compressor work efficiency, lack of effective guarantee of stability, affecting the subsequent treatment of garbage blocks, etc. The effect of small area, simple structure and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with specific embodiment, preparation method of the present invention is described in further detail:

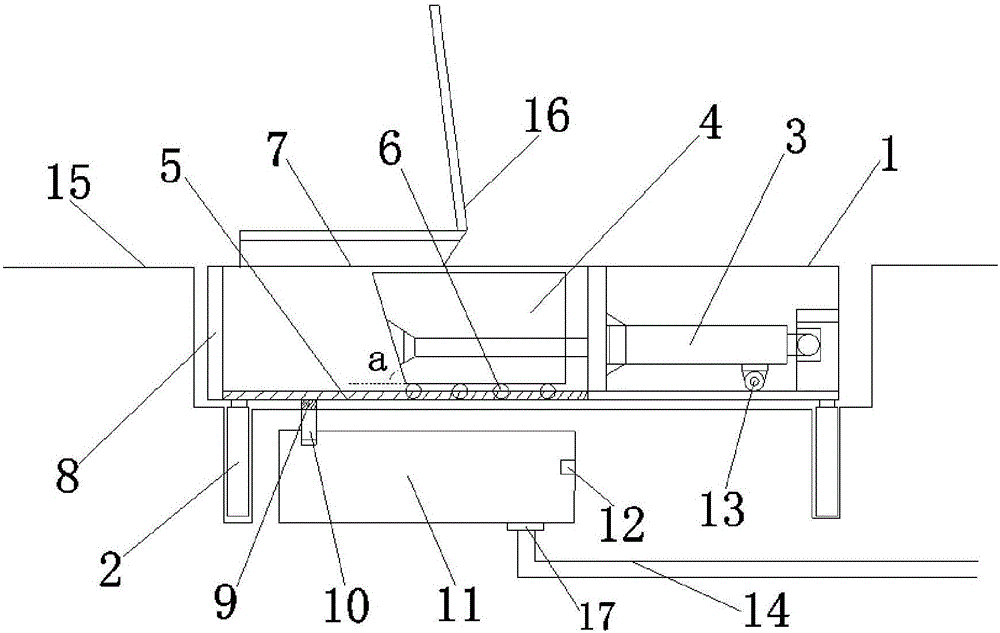

[0009] refer to figure 1 The shown underground horizontal garbage compressor includes a cabinet 1, four lifting cylinders 2 are arranged at the bottom of the cabinet 1, and the cabinet 1 and the lifting cylinders 2 are fixed in a pit 15, and the upper end of the cabinet is connected to the ground level.

[0010] Described chassis 1 is provided with master oil cylinder 3, and the cylinder body of described master oil cylinder 3 is fixed on the right end of chassis 1, and the load-bearing wheel 13 that is used to support cylinder body is connected with support below the cylinder body, and load-bearing wheel 13 is not easy to take place due to gravity. Bend for longer life.

[0011] The piston rod end of the main oil cylinder 3 is fixed with a pressure head 4, the angle a between the compression surface of the pressure head 4 and the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com